All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

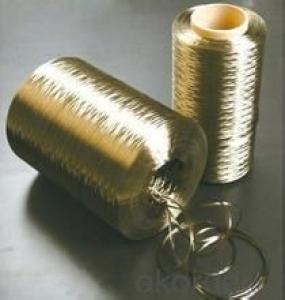

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is fiberglass roving used in the manufacturing of fiberglass insulation?

Fiberglass roving is used in the manufacturing of fiberglass insulation by being chopped into small strands and mixed with a binder. This mixture is then processed and formed into insulation batts or blown into spaces to provide thermal insulation for buildings. The roving acts as the primary reinforcing material, helping to enhance the insulation's structural integrity and thermal resistance properties.

How does fiberglass roving compare to carbon fiber roving?

Fiberglass roving and carbon fiber roving differ in terms of their composition and properties. Fiberglass roving is made from strands of glass fibers, while carbon fiber roving is composed of carbon filaments. Carbon fiber roving exhibits superior strength, stiffness, and lightweight properties compared to fiberglass roving. Additionally, carbon fiber roving has a higher tensile strength and greater resistance to heat and chemicals. However, fiberglass roving is generally more affordable and provides good insulation and corrosion resistance. Ultimately, the choice between the two depends on specific application requirements and budget considerations.

What are the common sizing options for fiberglass roving?

The common sizing options for fiberglass roving typically range from 300 tex to 4800 tex.

What are the different sizes and weights available for fiberglass roving?

The sizes and weights available for fiberglass roving can vary depending on the specific product and manufacturer. However, common sizes range from 200 tex (tex refers to the weight in grams per 1,000 meters) up to 4800 tex or even higher. The weights can range from 200 g/m² up to 2400 g/m² or more. It is important to consult with the supplier or manufacturer to determine the exact sizes and weights available for the specific fiberglass roving product desired.

Wholesale Fiberglass Roving from supplier in Latvia

Whether you are in the construction, automotive, or marine industry, our Fiberglass Roving products are designed to meet your specific requirements. Our sales team is dedicated to understanding your needs and providing you with the most suitable solutions. We offer competitive prices and flexible payment terms to ensure a seamless procurement process.

In addition to sales, we also provide comprehensive technical support. Our team of experts is well-versed in the technical aspects of Fiberglass Roving and can offer guidance and assistance throughout your project. Whether you need help with product selection, installation, or troubleshooting, we are here to support you every step of the way.

Furthermore, we understand the importance of timely and accurate quotations. Our dedicated team ensures prompt responses to your inquiries, providing you with detailed quotations that include all the necessary information. We strive to offer transparent and competitive pricing to help you make informed decisions.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to provide you with convenient and efficient procurement solutions. Whether you require small quantities or bulk orders, we have the capability to fulfill your requirements promptly.

Our years of market experience in Latvia have given us valuable insights into the local industry and customer needs. We understand the challenges and requirements specific to the Latvian market, enabling us to offer tailored solutions that enhance your projects. Our team is always up-to-date with the latest industry trends and regulations, ensuring that you receive the most relevant and reliable advice.

In summary, our specialization in supplying Fiberglass Roving in Latvia, combined with our comprehensive services, make us the ideal partner for your Fiberglass Roving needs. Contact us today to discuss your requirements and experience the convenience and efficiency of our procurement solutions.

In addition to sales, we also provide comprehensive technical support. Our team of experts is well-versed in the technical aspects of Fiberglass Roving and can offer guidance and assistance throughout your project. Whether you need help with product selection, installation, or troubleshooting, we are here to support you every step of the way.

Furthermore, we understand the importance of timely and accurate quotations. Our dedicated team ensures prompt responses to your inquiries, providing you with detailed quotations that include all the necessary information. We strive to offer transparent and competitive pricing to help you make informed decisions.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to provide you with convenient and efficient procurement solutions. Whether you require small quantities or bulk orders, we have the capability to fulfill your requirements promptly.

Our years of market experience in Latvia have given us valuable insights into the local industry and customer needs. We understand the challenges and requirements specific to the Latvian market, enabling us to offer tailored solutions that enhance your projects. Our team is always up-to-date with the latest industry trends and regulations, ensuring that you receive the most relevant and reliable advice.

In summary, our specialization in supplying Fiberglass Roving in Latvia, combined with our comprehensive services, make us the ideal partner for your Fiberglass Roving needs. Contact us today to discuss your requirements and experience the convenience and efficiency of our procurement solutions.