All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What factors influence the choice of steel coil grade for a specific application?

The choice of steel coil grade for a specific application is influenced by several factors including the required mechanical properties, corrosion resistance, formability, weldability, cost, and availability. The specific application's load-bearing requirements, environmental conditions, manufacturing processes, and desired product lifespan are also important considerations in determining the most suitable steel coil grade.

How are steel coils prepared for tube and pipe production in the construction sector?

Steel coils are prepared for tube and pipe production in the construction sector through a series of steps. Firstly, the coils are unrolled and flattened to create a continuous sheet of steel. Then, the edges are trimmed and the sheet is passed through a series of rollers to give it the desired shape and thickness. The sheet is then welded to form a continuous tube or pipe. Finally, the tubes or pipes are cut to the required length and undergo various finishing processes before being used in construction projects.

How are steel coils tested for corrosion resistance?

Steel coils are tested for corrosion resistance using various methods such as salt spray testing, humidity testing, and cyclic corrosion testing. These tests involve subjecting the coils to harsh environmental conditions and observing their resistance to corrosion over a period of time. Additionally, other techniques such as electrochemical testing and coating thickness measurement may also be utilized to assess the corrosion resistance of steel coils.

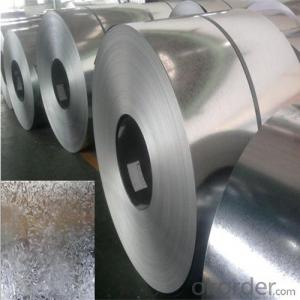

Wholesale Steel Coils from supplier in Hungary

Our team of experienced professionals is committed to delivering high-quality Steel Coils to meet your specific requirements. We work closely with our customers to understand their needs and provide tailored solutions that ensure optimal performance and cost-efficiency.

At our facility in Hungary, we maintain a large inventory of Steel Coils products, including hot-rolled coils, cold-rolled coils, galvanized coils, and stainless steel coils. Our products are sourced from trusted manufacturers and undergo rigorous quality control measures to ensure they meet industry standards.

In addition to supplying Steel Coils, we also offer a range of value-added services, including cutting, slitting, and packaging, to meet your specific project needs. Our technical support team is available to assist you with any inquiries or concerns, providing expert advice and guidance throughout the procurement process.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to offer competitive pricing, reliable delivery, and superior customer service. We are committed to building long-term partnerships with our customers and strive to exceed their expectations with every interaction.

Whether you are in the construction, automotive, or manufacturing industry, our Steel Coils products and services can help you achieve your project goals. Contact us today to learn more about how we can support your Steel Coils procurement needs in Hungary.

At our facility in Hungary, we maintain a large inventory of Steel Coils products, including hot-rolled coils, cold-rolled coils, galvanized coils, and stainless steel coils. Our products are sourced from trusted manufacturers and undergo rigorous quality control measures to ensure they meet industry standards.

In addition to supplying Steel Coils, we also offer a range of value-added services, including cutting, slitting, and packaging, to meet your specific project needs. Our technical support team is available to assist you with any inquiries or concerns, providing expert advice and guidance throughout the procurement process.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to offer competitive pricing, reliable delivery, and superior customer service. We are committed to building long-term partnerships with our customers and strive to exceed their expectations with every interaction.

Whether you are in the construction, automotive, or manufacturing industry, our Steel Coils products and services can help you achieve your project goals. Contact us today to learn more about how we can support your Steel Coils procurement needs in Hungary.