All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

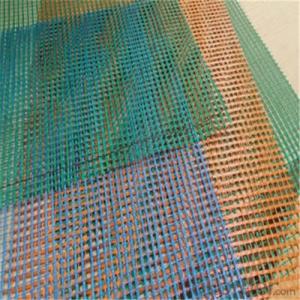

- - Fiberglass Mesh Cloth

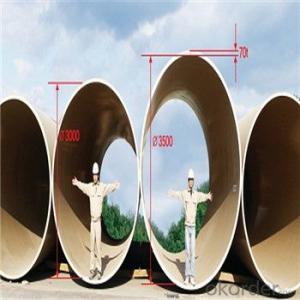

- - Composite Pipes

- - FRP Pultrusion Profiles

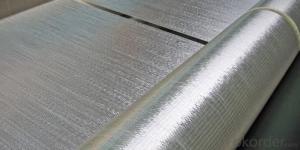

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Fiberglass Chopped StrandView More

Fiberglass Mesh ClothView More

Composite PipesView More

FRP Pultrusion ProfilesView More

Fiberglass Mat TissueView More

Fiberglass FabricsView More

Fiberglass MeshView More

Composite TankView More

Fiberglass Mesh tapeView More

PolymerView More

FRP Roofing PanelView More

Fiberglass RovingView More

Q & A

How do I cut fiberglass?

To cut fiberglass, you will need to take the following steps:

1. Ensure you are wearing protective gear, including safety goggles, a dust mask, and gloves.

2. Mark the area you want to cut with a marker or tape.

3. Use a fine-toothed saw or a rotary tool with a fiberglass cutting wheel for smaller cuts. For larger cuts, a jigsaw or reciprocating saw with a fine-toothed blade will work.

4. Apply gentle, steady pressure while cutting to avoid cracking or splintering the fiberglass.

5. Take breaks if needed to prevent overheating the cutting tool or blade.

6. After cutting, clean up any loose fiberglass particles and dispose of them properly.

Remember to always follow safety precautions and consult professional advice if unsure about the cutting process.

What are the steps involved in repairing fiberglass?

The steps involved in repairing fiberglass typically include preparing the damaged area by cleaning and sanding it, applying a layer of fiberglass resin or epoxy to reinforce the damaged area, placing a fiberglass cloth or mat over the resin, and applying additional layers of resin until the repair is built up and smooth. The final steps usually involve sanding and finishing the repaired area to match the surrounding surface.

How is fiberglass supply repaired?

Fiberglass supply is typically repaired by first identifying the damaged area, which may include cracks, holes, or delamination. The damaged section is then sanded down to remove any loose or damaged material. Next, a fiberglass repair kit is used to apply a layer of fiberglass cloth or mat over the damaged area. This is followed by applying a layer of fiberglass resin to fully saturate the cloth or mat and ensure a strong bond. Once the resin cures, the repaired area is sanded and smoothed to match the surrounding surface. Finally, a coat of gelcoat or paint is typically applied to restore the appearance of the repaired fiberglass supply.

How do you clean and maintain fiberglass products?

To clean and maintain fiberglass products, start by rinsing them with water to remove any loose dirt or debris. Then, use a mild detergent or soap and a soft cloth or sponge to gently scrub the surface. Avoid using abrasive materials or harsh chemicals that could damage the fiberglass. Rinse thoroughly and dry with a clean cloth. For maintenance, it is recommended to wax the fiberglass surface using a specialized fiberglass wax to protect it from UV rays and maintain its shine. Regularly inspect the product for any cracks or damage, and address them promptly to prevent further deterioration.

How does fiberglass compare to other materials like steel or aluminum?

Fiberglass offers several advantages over materials like steel or aluminum. Firstly, fiberglass is lightweight, making it easier to handle and transport. It also boasts excellent corrosion resistance, making it highly durable in harsh environments. Fiberglass is also a non-conductive material, making it ideal for applications where electrical conductivity is a concern. Additionally, fiberglass has a high strength-to-weight ratio, offering comparable strength to steel or aluminum while being significantly lighter. Lastly, fiberglass is a versatile material that can be molded into complex shapes, providing design flexibility.

Wholesale Fiberglass Supply from supplier in Hungary

Whether you are in need of fiberglass materials for construction, insulation, or any other application, we have you covered. Our product range includes fiberglass fabrics, rovings, mats, tapes, and resin systems, among others. We source our products from trusted manufacturers to ensure high quality and reliability.

In addition to sales, we also provide quotations tailored to your specific project requirements. Our team of experts analyzes your needs and provides competitive pricing and cost-effective solutions. We understand the importance of timely delivery, and we strive to meet your deadlines without compromising on quality.

Moreover, our technical support services are available to assist you throughout the entire process. From product selection to installation advice, our experienced team is here to address any queries or concerns you may have. We are committed to providing the highest level of customer satisfaction and ensuring that your projects are successful.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the backing and resources to guarantee comprehensive and efficient procurement services. Our strong global network enables us to offer competitive pricing and access to a wide range of products. With our expertise and knowledge of the Hungarian market, we can provide valuable insights and guidance for your projects.

Whether you are a contractor, distributor, or end-user, we are here to support your fiberglass supply needs in Hungary. Contact us today to discuss your requirements and let us assist you in finding the best solutions for your projects.

In addition to sales, we also provide quotations tailored to your specific project requirements. Our team of experts analyzes your needs and provides competitive pricing and cost-effective solutions. We understand the importance of timely delivery, and we strive to meet your deadlines without compromising on quality.

Moreover, our technical support services are available to assist you throughout the entire process. From product selection to installation advice, our experienced team is here to address any queries or concerns you may have. We are committed to providing the highest level of customer satisfaction and ensuring that your projects are successful.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the backing and resources to guarantee comprehensive and efficient procurement services. Our strong global network enables us to offer competitive pricing and access to a wide range of products. With our expertise and knowledge of the Hungarian market, we can provide valuable insights and guidance for your projects.

Whether you are a contractor, distributor, or end-user, we are here to support your fiberglass supply needs in Hungary. Contact us today to discuss your requirements and let us assist you in finding the best solutions for your projects.

Hot Search

- Fiberglass Chopped Strand in Luxembourg

- Fiberglass Mesh Cloth in Uruguay

- Composite Pipes in Nicaragua

- FRP Pultrusion Profiles in Hungary

- Fiberglass Mat Tissue in Guinea

- Fiberglass Fabrics in Zambia

- Fiberglass Mesh in Monaco

- Composite Tank in Guatemala

- Fiberglass Mesh tape in Angola

- Polymer in France