All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What measures can be taken to improve the corrosion resistance of aluminum profiles in marine environments?

There are several measures that can be taken to enhance the corrosion resistance of aluminum profiles in marine environments. Firstly, the aluminum profiles can be treated with an appropriate surface coating or finish, such as anodizing or powder coating, to create a protective barrier against corrosive elements. Secondly, using aluminum alloys with higher levels of corrosion resistance, such as marine-grade alloys like 5052 or 6061, can significantly improve the profiles' durability in marine conditions. Additionally, regular cleaning and maintenance, including removing salt deposits and applying corrosion inhibitors, can help prevent corrosion and extend the lifespan of the aluminum profiles in marine environments.

How are aluminum profiles used in the design and manufacturing of state-of-the-art laboratory equipment?

Aluminum profiles are extensively used in the design and manufacturing of state-of-the-art laboratory equipment due to their numerous advantageous properties. These profiles offer exceptional strength, durability, and corrosion resistance, making them suitable for various laboratory applications. They can be easily customized and shaped into different configurations to meet specific equipment requirements. Aluminum profiles also provide lightweight solutions, allowing for easy handling and transportation of the equipment. Moreover, their excellent thermal conductivity enables effective heat transfer in laboratory apparatus. Overall, aluminum profiles play a crucial role in creating innovative and high-quality laboratory equipment.

How do the properties of aluminum profiles differ from those of copper profiles?

The properties of aluminum profiles differ from copper profiles in several ways. Firstly, aluminum is much lighter than copper, making it more suitable for applications where weight is a concern. Secondly, aluminum has better corrosion resistance than copper, making it more durable in outdoor or corrosive environments. Thirdly, aluminum has higher thermal conductivity than copper, making it better suited for heat transfer applications. Lastly, aluminum is more cost-effective compared to copper, making it a popular choice for various industries.

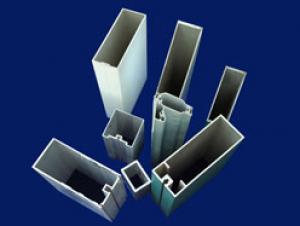

Wholesale Aluminum Profiles from supplier in Hungary

With our extensive product range, we can cater to various industries such as construction, architecture, manufacturing, and more. Our Aluminum Profiles are manufactured using high-quality materials and cutting-edge technology, ensuring durability and reliability.

Our team of experts is dedicated to providing excellent customer service, from initial inquiries to after-sales support. We offer personalized solutions tailored to your specific needs, ensuring that you receive the best product for your project.

In addition to sales and technical support, we also provide competitive quotes to help you make informed decisions. Our pricing is transparent and competitive, ensuring that you receive the best value for your investment.

As a subsidiary of CNBM, we benefit from the resources and expertise of a Fortune Global 500 company. This allows us to provide comprehensive procurement services, ensuring that you have a seamless experience throughout the purchasing process.

Whether you require standard Aluminum Profiles or customized solutions, we have the capabilities to meet your requirements. Our years of market development in Hungary have enabled us to establish strong relationships with suppliers and manufacturers, ensuring that we can provide you with the best products at the most competitive prices.

Contact us today to discuss your Aluminum Profiles needs in Hungary. Our team will be delighted to assist you and provide the necessary expertise and support for your projects.

Our team of experts is dedicated to providing excellent customer service, from initial inquiries to after-sales support. We offer personalized solutions tailored to your specific needs, ensuring that you receive the best product for your project.

In addition to sales and technical support, we also provide competitive quotes to help you make informed decisions. Our pricing is transparent and competitive, ensuring that you receive the best value for your investment.

As a subsidiary of CNBM, we benefit from the resources and expertise of a Fortune Global 500 company. This allows us to provide comprehensive procurement services, ensuring that you have a seamless experience throughout the purchasing process.

Whether you require standard Aluminum Profiles or customized solutions, we have the capabilities to meet your requirements. Our years of market development in Hungary have enabled us to establish strong relationships with suppliers and manufacturers, ensuring that we can provide you with the best products at the most competitive prices.

Contact us today to discuss your Aluminum Profiles needs in Hungary. Our team will be delighted to assist you and provide the necessary expertise and support for your projects.