Frequency Inverter Single-phase 220V class 185KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Product Name:CMAX-VCG15/P18.5T3 ~ CMAX-VCG18.5/P22T3

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

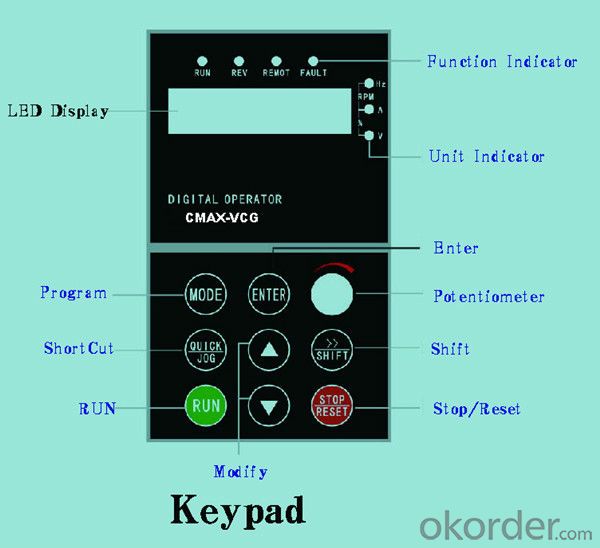

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

- Q:What does the base frequency 60Hz represent in the inverter?

- The schematic diagram of the basic frequency parameters of the converter is shown in figure.Below the fundamental frequency, the output voltage of the converter varies with the output frequency, and the V/F= constant is suitable for constant torque load characteristics.Above the fundamental frequency, the output voltage of the inverter maintains the same voltage rating of the power supply, which is suitable for constant power load characteristics.

- Q:Can the frequency converter 7.5KW take the motor with 11KW?

- A motor with variable torque with a constant torque converter, which is permissible. But the load and the motor are constant torque, and the frequency converter is also constant torque, so doing is the small horse cart. No, not recommended. Because the actual click can work continuously load is only 5.5kW, and then big, frequency converter can not stand.

- Q:PT100 temperature patrol instrument, when the converter is not open, the measurement is normal. Once opened, it shows completely disorder, and sometimes there are puzzling characters. How can I solve this problem? Please enlighten master!

- In the complex electromagnetic environment, AnyWay advocates the idea of digital front end, that is, in the vicinity of being measured, the signal will be digitized, and then the uploaded information will be uploaded to the host computer through digital communication. Digital transmission is much better than analog transmission in anti-interference ability. If the electromagnetic interference is very large, the transmission line can be changed into optical fiber transmission. In this way, the transmission link can completely avoid interference.

- Q:What does Ro1c mean on a converter?

- Frequency converter (Variable-frequency, Drive, VFD) is the application of frequency conversion technology and microelectronics technology, by changing the power supply frequency of the motor to control AC motor power control equipment. The frequency converter is mainly composed of rectifier (AC DC converter), filter, inverter (DC AC converter), brake unit, drive unit, detection unit, micro processing unit and so on.

- Q:What is the main function of the frequency converter on the machine tools?

- Where is the difference between soft starter and converter?

- Q:What does a frequency converter do?

- What is the starting current and starting torque of the motor when the inverter is in operation?Using frequency converter operation, with the acceleration of the motor, accordingly improve the frequency and voltage, the starting current is limited to 150% rated current (according to the type of machine is 125%~200%). The starting current is 6~7 times of direct starting with the mains frequency power supply, so the mechanical and electrical impact will be produced. It can start smoothly with frequency converter (longer starting time). The starting current is 1.2~1.5 times the rated current, the starting torque is 70%~120%, the rated torque; for the inverter with automatic torque enhancement, the starting torque is above 100%, and the full load can start.

- Q:Why does harmonic generator produce harmonic? What's his working principle?

- The working principle of the inverter is the first AC into DC, because the alternating current is not directly change its frequency, according to the parameter setting of the machine, and then the DC into AC power, and then drag to load.

- Q:Heating inverter commissioning steps

- The no-load connection test of the frequency converter will connect the grounding terminal of the frequency converter to the ground 1. 2 the power input terminal of the frequency converter is connected to the power supply through the leakage protection switch. 3 check the frequency converter display window factory display is normal, if not correct, should reset, or request exchange. 4 familiar with the operation key of frequency converter. The inverter has run in general (RUN) and stop (STOP), programming (PROG), P (DATAPENTER), the data confirm the increased (UP, 3), reduce (DOWN, 6) and other key definitions of different inverter operation keys are basically the same. In addition, some inverters also monitor (MONITORPDISPLAY), reset (RESET), inch movement (JOG), shift (SHIFT) and other functional keys.

- Q:What's the use of switching frequency of converter?

- The chopper device also has switching life, the higher the switching frequency, the shorter the life of the inverter, and will reduce the inverter output current and power. The smaller the chopping frequency, the higher harmonic content and the more serious harmonic pollution.

- Q:What is the difference between a frequency converter and a servo controller?

- Servo motor servomotorAutomatic control of micro motor actuator device used for. Executive motor. Its function is to convert electrical signals into angular or angular velocities of rotating shafts.Servo motors are divided into two categories: DC and dc. AC servo motors work in the same way as AC induction motors. Wf excitation winding and control winding WcoWf is connected to a constant AC voltage of two phase space displacement electric angle of 90 degrees on the stator, the change of Wc on AC voltage or phase is applied to achieve the purpose of running motor control. AC servo motor with stable operation, good controllability, fast response, high sensitivity and mechanical properties and nonlinear adjustment characteristic index (strict requirements are less than 10% and less than 15% ~ 15% ~ 25%) etc.. The principle of DC servo motor is the same as that of general DC motor. The motor speed is n

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Frequency Inverter Single-phase 220V class 185KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords