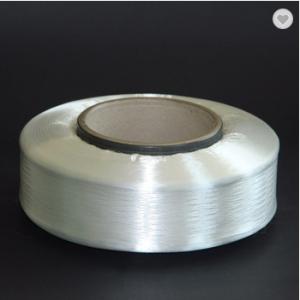

Eco-Friendly High Strength Fully Drawn Yarn FDY for Knitting Weaving Sewing

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of FDY Yarn

Material | 100% polyester |

Type | FDY (Fully Drawn Yarn), semidull |

Structure | Multifilament Yarn, Continuous Filament |

Color | White and Black |

Feature | Eco-Friendly, High Strength, |

Application | Knitting, Weaving, Sewing, Embroidery |

Specification | 11-167dtex, 12-144F |

Production Capacity of FDY Yarn

The production capacity is 200,000 TONS per year for now and it will be of 500,000 per year after the erection of the second production line.

Application and suggestion:

1. The adhesive of two layers of sports shoe Upper material —FDY 50D/75D

2. Soft curtain, Zebra curtain, Roman curtain—FDY 75D/150D

3. Vertical blinds—FDY 250D

4. Filter net for air condition—FDY 30D/50D/75D/150D

5. Electromagnetic wire: PET-Glass fiber blended fiber—FDY 50D/75D

6. Garment lining cloth for suit, tie, hat, etc. —FDY 150D/50D/420D

7. Warp knitting fabric such as: Stiff mesh fabric, medical/food filter net, inner car decoration.

8. Top-grade eco-friendly filter material

9. Other applications: protective gloves, dust gauze, top-grade window screen, invisible screen, etc.

Advantage of Us:

Subsidiary of Stated-owned group, reliable and trustable

Industry leader in the PET chip and yarn fields

On time delivery and prompt response

Well-funded and accept different kinds of payment terms

Workshop

- Q:What is the textile bobbin?

- A plurality of holes are formed in the tube wall of the bobbin so that the cheese yarns wound around the bobbin are easily humidified by these holes.

- Q:What is the reason for the low strength of cotton yarn

- We found in the spinning frame yarn problems, roving weight qualified, and later found in the apron with a plot of flowers, may affect the yarn less stretch.

- Q:What does JC40S cotton yarn mean?

- Cotton yarn is made of cotton fiber by spinning the yarn, processed by the stock after the cotton thread. According to the different spinning process, can be divided into carded yarn and combed yarn.

- Q:What is the cheese yarn?

- Usually called "cheese yarn"; size - such as diameter about ∮ 250mm or so, the height of about 150mm or so different specifications, requiring no joints (air splicing) or small and fast joints, and forming a good internal and external tension evenly.

- Q:What is yarn support?

- Metric count is also the weight of the system, so the greater the number of yarn finer. Cotton textile wool textile industry have to use.

- Q:From the yarn to the finished textile fabric production process

- Including aliphatic PA, fat-aromatic PA and aromatic PA. Among them, the aliphatic PA varieties, large output, widely used, the name of the monomer by the specific number of carbon atoms

- Q:Textile class 21 yarn, 32 shares of what is the meaning of goods ah

- Such as the yarn, 21 is a single yarn, 32 shares, equivalent to 16 yarn. So 32 shares more than 21 single yarn to be thick. The yarn is also more expensive than the single yarn.

- Q:What is the process of towel in the textile?

- Determine the yarn count, warp and weft density, the number of warp yarns and weft yarns (especially yarn-dyed), with a number of pieces, wearing a reed method, jacquard to determine the installation of wear method (in layman's terms, , Wear, mix wear method), reed width, shaft width, yarn consumption, hair times, under the specifications and weight, and so on

- Q:How much does it cost to do a small cotton textile mill?

- General brocade and roll machine together to sell together. A Qinghua with 3-5 sets of carding, two parallel, 1-2 sets of coarse sand machine, 8-16 spinning machine!

- Q:Textile waste silk (abandoned side yarn) what purpose ah?

- Textile waste silk (discarded yarn) is a non-woven textile raw materials, usually re-opened, non-woven non-woven equipment production, should be 90% of the product is the production of non-woven fabrics. The reason for this is as follows

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Eco-Friendly High Strength Fully Drawn Yarn FDY for Knitting Weaving Sewing

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords