Refractory Light Brick Thermal Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Light Brick Thermal Insulating Fire Brick

High alumina insulating fire brick is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina Insulating Fire Brick are made of selected high alumina bauxite, kaolin caly, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature.

Product Applications:

High alumina insulating fire brick are ideal for use in the below applications

Building materials for blast furnace

Building materials for hot-blast stove

Building materials for coke oven

Building materials for steel making furnace

For construction material in steel industry

For ladle

Product Advantages:

CNBM has success in its High alumina insulating fire brick due to their cost-effectiveness and excellent insulating properties. The refractoriness of magnesia chrome bricks are more than 2000°C, and the refractory under load is a above 1550°C.Good steady volume in high temperature, the performance of meeting sudden cold and sudden hot is better than magnesia bricks.

Main Product Features:

Excellent thermal stability

High refractoriness under load

Chemical stability and anti-corrision

Small high temperature creep rate

Excellent thermal shock resistance

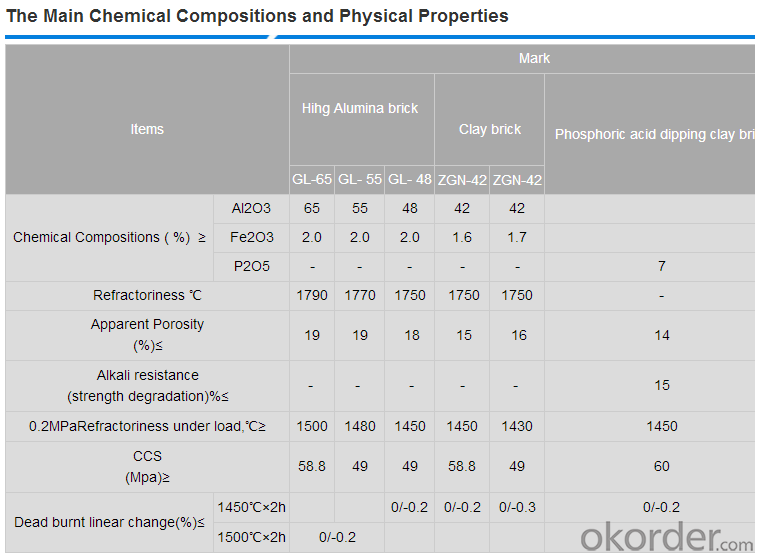

Product Specifications:

FAQ:

Q1: Are you a manufacture or trader?

A1: Factory+trade (mainly for manufacturing, also do some business of related products).

Q2: What's the MOQ of trial order?

A2: No limit,We can offer the best suggestions and solutions according to your requirements.

Q3: After an order is confirmed,when to deliver?

A3: According to your order quantity, normally, 15-25 days after deposit received.

Q4: Is your company accept customization?

A4: We have our own factories and excellent technical team, and we accept OEM service.

Product Picture

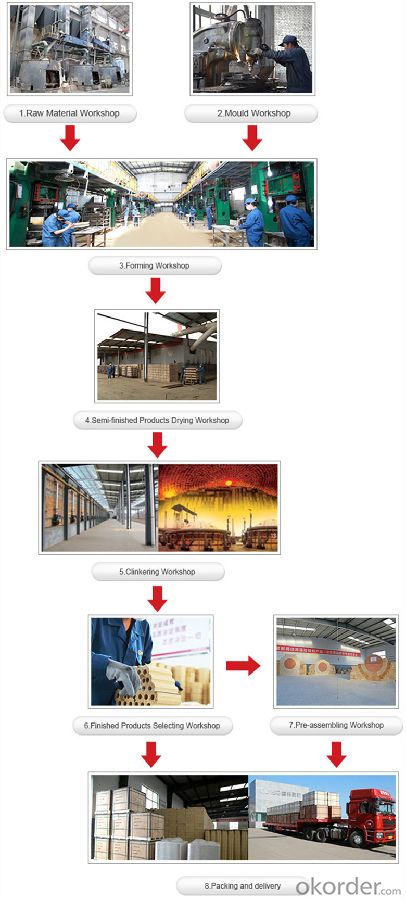

Produce Processing

- Q:Can insulating fire bricks be used in solar power plants?

- Insulating fire bricks have the ability to be utilized in solar power plants. These bricks are specifically designed to possess exceptional thermal insulation properties, thus making them suitable for various applications that demand resistance to heat and energy efficiency. Solar power plants frequently experience high temperatures and the necessity to retain heat, particularly in concentrated solar power (CSP) systems. By using insulating fire bricks to line the walls and floors of CSP receivers and thermal storage systems, the loss of heat can be minimized and the conversion of solar energy into electricity can be maximized. Furthermore, insulating fire bricks can also find utility in other components of solar power plants, such as the insulation of solar panels or the construction of solar tower structures.

- Q:What is the typical density of an insulating fire brick?

- The typical density of an insulating fire brick can vary depending on the specific composition and manufacturing process. However, in general, insulating fire bricks have a lower density compared to regular fire bricks. The typical density of an insulating fire brick can range from 0.8 g/cm³ to 1.2 g/cm³. This lower density is achieved by incorporating insulating materials like lightweight aggregates or organic fibers into the brick's composition, which helps to reduce heat transfer and increase thermal insulation properties.

- Q:Can insulating fire bricks be used in chimneys or flue systems?

- Yes, insulating fire bricks can be used in chimneys or flue systems. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent insulation. They are commonly used in applications where heat needs to be retained or reflected, such as in chimneys or flue systems. These bricks are capable of withstanding temperatures up to 3000°F (1650°C), making them ideal for use in environments with extreme heat. Additionally, their insulating properties help to minimize heat loss, improve energy efficiency, and prevent damage to surrounding structures. However, it is important to note that insulating fire bricks should be installed according to the manufacturer's guidelines and local building codes to ensure safe and proper usage.

- Q:Can insulating fire bricks be used in the construction of lime production linings?

- Yes, insulating fire bricks can be used in the construction of lime production linings. Insulating fire bricks are designed to have low thermal conductivity, which makes them excellent for applications where heat insulation is required. In lime production, high temperatures are required for the calcination process. Using insulating fire bricks in the construction of lime production linings helps to reduce heat loss and improve energy efficiency. Additionally, insulating fire bricks are lightweight and easy to handle, which makes them suitable for lining various parts of lime kilns and other equipment used in the lime production process. Overall, using insulating fire bricks in lime production linings can help to optimize the production process and improve the overall performance of lime production facilities.

- Q:The insulation layer destroyed after use of cement paste and tiling

- The most certain and the method can increase the area of the balcony is to eradicate the insulation layer exposed after cement wall tiles.

- Q:What are insulation bricks for? Do not use high-rise buildings on the ah?

- Buildings usually do exterior thermal insulation, such as EPS board, polyphenyl board and so on

- Q:Do insulating fire bricks require any maintenance?

- Insulating fire bricks, also known as refractory bricks, are designed to withstand high temperatures and provide excellent insulation properties. One of the advantages of insulating fire bricks is that they require very little maintenance. These bricks are made from special materials that have high resistance to heat and thermal shock. As a result, they do not crack or break easily, reducing the need for frequent repairs or replacements. However, like any other material, insulating fire bricks can accumulate dust or debris over time. Regular cleaning is recommended to maintain their effectiveness and prolong their lifespan. This can be done by using a soft brush or vacuum cleaner to remove any loose particles. In addition, it is important to inspect the bricks periodically for any signs of damage, such as cracks or erosion. If any issues are identified, they should be addressed promptly to prevent further deterioration. Overall, while insulating fire bricks do not require extensive maintenance, regular cleaning and inspection are essential to ensure their optimal performance and longevity.

- Q:Are insulating fire bricks resistant to moisture or water damage?

- Insulating fire bricks are generally resistant to moisture or water damage. These bricks are designed to have low porosity and high density, which helps prevent water absorption. Additionally, they are typically made from materials like alumina or silica, which have inherent resistance to moisture. However, it is important to note that no material is completely impervious to water, and prolonged exposure to moisture or water can still have some effect on the insulating fire bricks over time. Therefore, it is recommended to take necessary precautions, such as applying appropriate sealants or coatings, to enhance their resistance to moisture or water damage in certain applications.

- Q:Can insulating fire bricks be used in drying ovens?

- Yes, insulating fire bricks can be used in drying ovens. These bricks are designed to withstand high temperatures and provide insulation, making them suitable for use in ovens where drying processes occur. They help to maintain a consistent and efficient heat distribution, ensuring effective drying of the materials inside the oven.

- Q:Can insulating fire bricks be used in the construction of refractory coatings?

- Yes, insulating fire bricks can be used in the construction of refractory coatings. Insulating fire bricks are designed to have low thermal conductivity, making them suitable for insulating applications. When used as a component in refractory coatings, they can help to enhance the insulation properties and provide thermal protection.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory Light Brick Thermal Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords