Electrical Tinplate, JIS G3303 Standard For Food Cans & Industrial Cans

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tinplate, as the name suggests, is coated on both sides with pure tin at various coating weights between 1 and 12 grams per square meter.

It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

TINPLATE SPECIFICATION

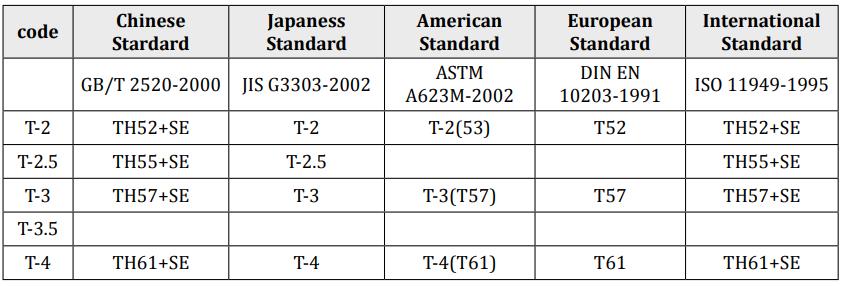

1.Reference standard: GB/T 2520-2000,JIS G3303-2002 and DIN EN 10203-1991

2. Raw material: MR and SPCC

3.Thickness: 0.13 to 0.5mm

4.Width: 600-1050mm

5.Coil diameter: ID 420mm or 508mm

6.Temper: T1~T5,DR8~DR10

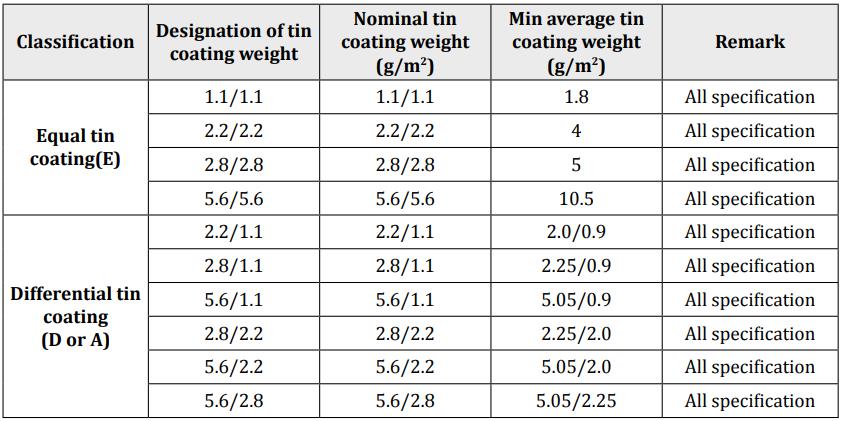

7.Tin coating: 1.1g~11.2g, We can produce according to customer's requests.

8. Applications: paint, chemical and other usage can make battery, electric cable and other industries

9. Package: anti-rust paper, corner protected. Sheets or coils according customer's requests

STANDARD

SURFACE

| Marks | Surface state | Characteristics |

| B | Bright rough | Glazed surface obtained after melting treatment of electrotinned smooth raw material strip featuring certain oriented rubstone figure. |

| RR | St hStone rough | Glazed surface obtained after melting treatment of electrotinned raw material strip featuringg p g certain oriented rubstone figure. |

| S | Silver rough | Glazed surface obtained after melting treatment of electrotinned raw material strip with rough matt surface. |

COATING

APPLICATION

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

- Q:How does tinplate perform in terms of temperature resistance?

- Tinplate performs well in terms of temperature resistance, as it can withstand high temperatures without losing its structural integrity or experiencing significant changes in its physical properties.

- Q:How can recycled tin cans be recycled?

- The broken material is separated by the air whirling sorting system, and the metal and nonmetal are separated from each other. Moreover, the whole system is equipped with a dust removing device to minimize the damage caused by dust pollution in the process of production.Tin tins, crushing machines, equipment and maintenance costs are low: equipment design is reasonable, well made, extending the service life of equipment, reducing the use and maintenance costs of equipment.

- Q:What are the main applications of tinplate in the tobacco industry?

- Tinplate is commonly used in the tobacco industry for packaging cigarettes and other tobacco products. It provides a protective barrier against moisture, light, and oxygen, helping to preserve the quality and freshness of the tobacco. Tinplate also offers a visually appealing and durable packaging solution, contributing to the overall branding and marketing of tobacco products. Additionally, tinplate can be easily decorated or embossed, allowing for intricate designs and customization options that enhance product differentiation on store shelves.

- Q:What are the main applications of tinplate in the beverage industry?

- Tinplate is mainly used in the beverage industry for the production of cans and packaging materials. It provides a protective barrier against corrosion, ensuring the product's integrity and extending its shelf life. Tinplate cans are lightweight, easily stackable, and offer convenient storage and transportation. Additionally, tinplate's ability to be printed and decorated makes it ideal for branding and marketing purposes in the beverage industry.

- Q:How does tinplate compare to other types of packaging materials?

- Tinplate has several advantages over other types of packaging materials. It is highly durable, providing excellent protection for the contents. Tinplate also has good resistance to corrosion, ensuring the product remains fresh and uncontaminated. Additionally, it is lightweight and easily recyclable, making it an environmentally friendly option. Furthermore, tinplate offers a visually appealing and versatile packaging solution, with various printing and shaping options available.

- Q:What are the advantages of using tinplate for pharmaceutical packaging?

- There are several advantages of using tinplate for pharmaceutical packaging. Firstly, tinplate is highly resistant to corrosion, ensuring the integrity and safety of the pharmaceutical products. Secondly, tinplate provides excellent barrier properties, protecting the contents from moisture, light, and oxygen, which can degrade the quality and efficacy of medications. Additionally, tinplate is sturdy and durable, providing adequate protection during transportation and storage. Finally, tinplate is easily recyclable, making it an environmentally friendly choice for pharmaceutical packaging.

- Q:What are the cost considerations of using tinplate packaging?

- The cost considerations of using tinplate packaging include the price of the tinplate material itself, manufacturing and production costs, transportation and storage expenses, as well as potential additional costs for labeling or customization. Additionally, tinplate packaging may require specialized equipment or machinery for production, which could add to the overall costs. However, tinplate packaging offers advantages such as durability, protection against moisture and air, and its recyclability, which can contribute to overall cost savings in terms of product quality, shelf life, and sustainability.

- Q:Can tinplate be used for electrical appliances?

- Yes, tinplate can be used for electrical appliances as it provides a durable and corrosion-resistant coating that can protect the appliances from moisture and other external elements. Additionally, tinplate has good electrical conductivity properties which make it suitable for electrical applications.

- Q:How is tinplate used in the manufacturing of electronic devices?

- Tinplate is commonly used in the manufacturing of electronic devices as it provides an ideal material for the production of casing and outer components. Its corrosion-resistant properties help protect the internal circuitry from environmental factors, ensuring durability and longevity of the electronic device. Additionally, tinplate's malleability allows for easy shaping and customization, enabling manufacturers to create sleek and aesthetically pleasing designs.

- Q:Can tinplate be used for kitchenware?

- Yes, tinplate can be used for kitchenware. Tinplate is a type of steel coated with a thin layer of tin, which provides corrosion resistance and makes it suitable for food contact applications. It is commonly used for making cans, containers, and other kitchen utensils due to its durability, easy cleaning, and ability to keep food fresh.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electrical Tinplate, JIS G3303 Standard For Food Cans & Industrial Cans

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords