waterproof wooden plastic landscaping flooring WPC

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

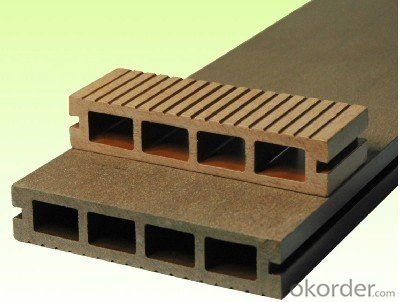

Introduction of Wood Plastic Composite Decking

The WPC decking is a new material, combine the nature look of a wood deck with the advantages of a weather-resistant, stable, easy to clean, and sturdy high-tech material and quite follow the trend of wood substitute.

Application of Wood Plastic Composite Decking

widely used for outdoor decking floor,Wall panel.railing,fence,bridge,dock,gloriette,gazebo,boardwalk,etc

Advantage of Wood Plastic Composite Decking

1. With the look of the natural wood but less timber problems, Approx. 90% recycled materials

2. Weather resistant, suitable from -40 to 60 °C

3. Resistant to termite and insect attack, will not split, rot or warp

4. Cuts and drill like timber

5. Requires no painting, no glue, low maintenance effort

6. Easy to install and clean

Packing of Wood Plastic Composite Decking

Packaging Detail | 112pcs per pallet, 16pallets per 20ft, 24 pallets per 40ft. pallet size:290x105x1375px |

Delivery Detail | 15 days after received the deposit |

Pictures of Wood Plastic Composite Decking

Specification of Wood Plastic Composite Decking

component | 30%HDPE+60%bamboo/wood fiber component+10%chemical additives |

Length | 2.2m, 2.9m, and 5.8m or customized |

Size | 140X20mm,150X25mm,145 X21mm,145 X25mm, etc |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE, Walnut, gray stone, Cedar, Rosewood) and we can adjust the new color according to the order requirement |

FAQ

We have organized several common questions for our clients,may help you sincerely.

1. How about your company?

Our company is a world class manufacturer & supplier of Wood Plastic Composite and is one of the large-scale professional investment Wood Plastic Composite bases in China. Annually more than 1000 containers of Wood Plastic Composite bases are exported to markets in Europe, North America.

2. How to guarantee the quality of the products?

We can supply certificates, including ISO9001, ISO14001, CE, FSC Certificate, "REACH" Test Reports by SGS; Intertek Test Report by ASTM standard..etc.

3. How to install the WPC decking?

Installation tool: electric saw (desk type or portable),churn drill, electric portable drill and driver

Decking and accessories: 1.decking 2.joist 3.metal clip 4. plastic expansion screws 5.start clip 6.fascia

Installation step:

1. Fix the joist. 2. Decking installation. 3.Fascia installation

- Q: Environmental protection is also not out of date, ask the old fire master.

- I recommend buying a solid wood compound. Reason: 1, the price of solid wood 2, the composite style and more, 3, composite nail teeth feel the taste of picking up the pulp easy to take care of 4, the composite easy to disassemble, do not like to change the other ok ~ hey, Because cheap ~ 5, solid wood composite has a lot of style specifications, are good, who said no sense of foot! ~

- Q: How does the composite wood floor rise?

- Keep ventilated, or flatten with heavy objects

- Q: This type of floor to hear someone say good. But the price is not expensive? More

- Solid wood flooring are expensive, the specific price depends on what you buy wood, and to buy the floor of the market is also concerned about the high-end places will drive up the price is relatively high I suggest you buy solid wood or do not buy composite flooring is better, under the composite floor on a layer of moisture-proof foam paper, the elderly have children at home, it is not warm, especially children like summer barefoot will be cold. If you do not like the traditional floor of the kind of wood, then there is a kind of smart buckle floor, the price is more expensive, the actual nature and the composite floor almost, but will be a gap between the cement and the ground, and smart The thickness of the floor is thicker than the rest of the floor, because every floor of the floor is supported by a few points, and the naked eye may look thicker. So light foot on the floor will not be damp cold, I see the price of about 300 to 800 per bucket arm Juju bracelet with the delivery of square meters have, I value the wood is a bit expensive for me, Did not buy My home now buy Acacia wood is the traditional solid wood flooring, is bought last summer, the first batch of goods in the high-end building materials market is more than 500, the number of buy less, the nearest place in another place to buy, is the general wholesale market , After the price is less than 250, the quality is the same, so before buying things or shop more important than three.

- Q: How is the elephant parquet?

- The elephant solid wood flooring is very good ah, in the solid wood flooring industry, the image of the brand is still very advantageous, but the price of fines and reincarnation of the old group is more expensive, buy or according to individual economic conditions The If you need cost-effective, then you can consider the next Linchang floor, Kenya Asia, peace of mind, Chunzhou Oude, Hao Ge these are also quite good, you can go to contrast. China's top ten brands to buy the top of the top ten solid wood flooring brand list, there is time to go there to see the query Oh

- Q: Is the laminate flooring orange and can you paint on the green above? / More

- Do not need to paint the paint, if you have to brush, you will find health is more difficult to do, strengthen the surface of the composite floor is aluminum oxide, the paint is easy to fall off, especially after the paint is more ugly The Moreover, the processing of the factory is better than the artificial nature, artificially remove the previous paint and brush on the new, not only not easy to ensure stability, and will bring room for the immeasurable pollution, that is, the use of so-called good paint is also possible The Paint contained in toluene and xylene, the health of their families.

- Q: Why is the middle of the composite floor plate foam

- First, the quality is not good, the second is damped. I hope my solution will help you

- Q: What is the plastic floor? What is the composite floor?

- Plastic flooring generally refers to PVC flooring, as well as wood flooring. The floor has the material of the material, water resistance, generally suitable for public places. Composite floor, in a broad sense, refers to the structure by the layers of composite floor, such as: laminate flooring, multi-layer parquet, part of the bamboo flooring. As for the floor resistant to burning cigarettes, there are provisions of the national standard. PVC flooring, laminate flooring and other surface with aluminum oxide wear layer, more resistant to burning, the general bamboo, wood flooring surface is paint, not smoke cigarette burner.

- Q: Thinking of replacing 12X12 vinyl kitchen covering.Plz. give highlites of the install and if you liked the results.Thnx.

- looks real good so far most difficult decision was where to start I started in the doorway did two rooms

- Q: Home to decorate, and intend to shop laminate flooring, do not know what is the need to pay attention to it, understand the pro-oh ~ more

- Strengthen the floor to pay attention to the following basic substrate: pine peeling substrate for the superior, the other substrate no matter what he said there is no pine good. Pine wood fiber length, and thus less glue, formaldehyde content is relatively small, the substrate into a golden yellow, black base material or non-peeling, or a lot of mixed wood mixed together, it is recommended not to buy, and It is important that the base of the pine is better than the waterproofing of the other substrates, and that the northerners have experience (the wood in the northern bathhouse is mostly pine). See the number of wear-resistant: home two standard 4000 home a standard 6000 public places standards at least 9000. This to see their own product description to go. The number of wear-resistant speed is not enough to strengthen the floor can not use the dome of the dome of the mouth of the light-bodied dog how long the surface of the layer of paper will fall off, nausea to death formaldehyde content: the best E1 level to see the lock: to strengthen the floor do not choose Flat buckle got. As for how to distinguish between flat or non-flat deduction, you directly ask him to install the floor when the need to glue the floor to fight together, if that is flat buckle, do not choose. Installation of plastic is very environmentally friendly. Look at the brand: big point of the brand is better than the small brand. After-sales service is guaranteed all hands, hope to adopt

- Q: New house ready to renovate, bedroom inside want to use composite floor, but I heard that the composite floor radiation, is true or false ah? The The More

- No radiation at ease

Send your message to us

waterproof wooden plastic landscaping flooring WPC

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords