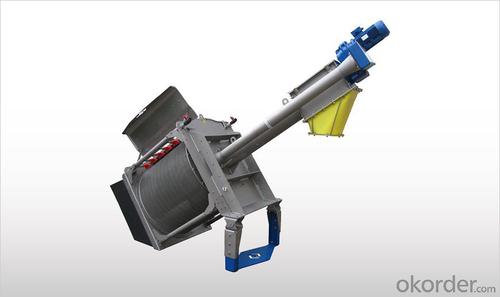

WASTEMASTER FTR Rotary Drum Screens

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

WASTEMASTER FTR is a rotating drum screen designed to combine separation of solids present in effluents with compacting and de-watering of the screenings thus obtained.

---

WASTEMASTER FTR is a rotating drum screen designed to combine separation of solids present in the effluent with compacting and de-watering of screenings thus obtained. WASTEMASTER FTR consists of a rotating drum screen basket, a conveyor screw (with self-cleaning SINT drainage liner) and, as an option, a compacting module. WASTEMASTER FTR is a space-saving machine that combines multiple functions in one unit only:

screenings separation, drainage, conveying and de-watering.

Depending on the screen size of the drum and screen mesh dimensions, flow rates of up to 2,000 litres per second can be obtained.

Function

The conveyor screw consists of a shaftless spiral which collects the solids from the bottom of the screen conveying them without any risk of clogging.

The compactor in the upper part, equipped with a washing section for diminishing organic fractions, uses the conveyor screw for compacting and de-watering of the screenings.

Features

Fabricated parts entirely manufactured from 304 L / 316 L SS

Shaftless conveyor screw manufactured from 304 / 316 SS or special high resistance steel

Perforated or wedge wire drum screen in various mesh sizes

Versatile unit for concrete channel installation

No outlet end bearing, no intermediate bearings

Solids extraction of up to 15 m3/h

Self-supporting drum and extracting screw

Single drive unit

Benefits

High flow rates

Obstacle-free inlet

SINT liner and jagged screw flight for high removal rate with difficult materials such as fibres

Single drive unit with low energy consumption

Options

Compacting module

Tank

Perrot valve

Overflow

Screen basket mesh

Support bracket kit

Drive guard

Alternative voltage and frequency

Alternative degree of motor protection

Control panel

Main drainage

Pipe washing system

Pipe heating system

Discharge module heating

Accessories

Bag-clamping system

Endless tube

Outlet support collar

Send your message to us

WASTEMASTER FTR Rotary Drum Screens

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords