Variable Frequency Drive 3.3KV 400KW Inverter

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General

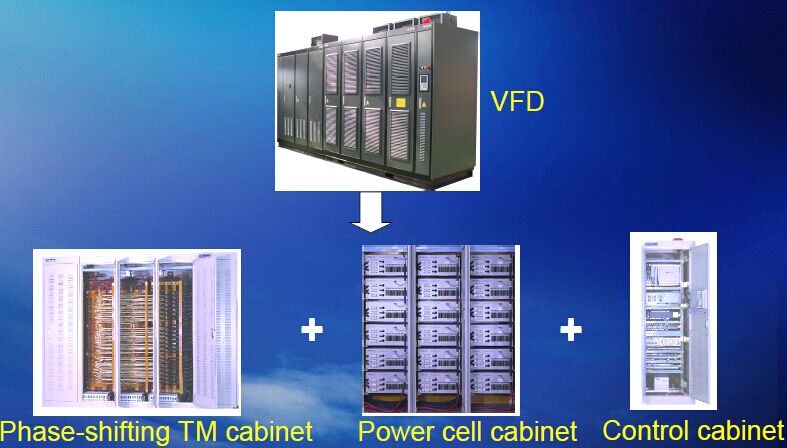

CNBM high Voltage Variable Frequency Drives are designed to be highly reliable with high-performance, yet easy to use.It can satisfy users' need for changing the speed of fans or pumps,as well as improve the productivity.

The series are compatible with all types of three-phase medium voltage asynchronous motors.

Specification and advantages :

1. Voltage resource VFD, direct input of 3,3.3,4.16,6,606 and 10 kV,direct output of3,4.16, 6,6.6 and10 kV,no output transformer necessary. High input power factor, low harmonic current, no power factor corrective capacities and harmonic filters required.

2. Sinusoidal multi-level PWM output waveform, no output filter required, can be directly connected to standard induction motor,no harm to the insulation of the cable or the motor, low harmonics of the motor, reduction of vibration of the shafts or the vanes,with the maximal length of the output cable of 1000m.

3. Friendly human-machine interface.

4. Modular design of the power circuits simplifies maintenance routine.

5.The medium voltage circuits are linked with the controller by the optical fibers,which keep the controller safe and away from the disturbance.

6. The complete fault monitor circuit, accurate fault alarm and protection.

7. Integrated cooling blower

8. The control logic can be conveniently changed with the help of the integrated PLC.

9. Offer both field control and remote control in monitor station, providing convenient controlling options.

10. Support most of the industrial standard protocols (Profibus, Modbus, TCP/IP, etc.)

11. Compatible with industrial standard signal of 0-10V/4-20mA

12. Able to operate at either open loop control or closed loop control status with the integrated PID regulator.

Specification

Model | A03/050~ | A03/100~ | A03/175 ~A03/220 | A03/220~A03/400 | A03/220~A03/610 |

Capacity(kVA) | 250~630 | 630~900 | 900~1150 | 1150~2000 | 2000~3125 |

Rated output current (A) | 50~100 | 100~175 | 175~220 | 220~400 | 400~610 |

Motor power (kW) | 200~400 | 400~710 | 710~900 | 900~1600 | 1600~2500 |

Input frequency | 45Hz~55Hz | ||||

Rted input voltage | 3000V±10% | ||||

Input power factor | 0.95 (>20%load) | ||||

Efficiency | 0.96 with rated load | ||||

Output frequency | 0.5Hz~120Hz | ||||

Frequency resolution | 0.01Hz | ||||

Overload capacity | 120% 1 min, 150% immediately | ||||

Analogue input | 0~10V/4~20mA | ||||

Analogue output | 0~10V/4~20mA | ||||

Acceleration/deceleration time | 0.1~3000s | ||||

Digital output/input | expanded according to requirement | ||||

Ambience temperature | 0~40°C | ||||

Storage/transport temperature | -40~70°C | ||||

Cooling | air cooling | ||||

Ambience humidity | <90% without condensation | ||||

Altitude | <1000 m | ||||

IP class | IP20 | ||||

Size(mm)(W×H×D) | 3300×2480×1200 | 4900×2480×1200 | 6000×2580×1300 | ||

Weight (kg) | 3000 ~5000 | 5000 ~7300 | 7300~9200 | ||

- Q: What is the difference between the electronic governor and the frequency converter on the motor speed regulation?

- Electronic governor is for single-phase motor, by changing the access winding resistance and capacitance to adjust the motor speed, the speed of the power supply power for the output does not change, so this speed is not an energy Type of speed control methods, such as home for the use of fans and the like. Inverter speed is the original direct input three-phase asynchronous motor power first access to the inverter, in the inverter through the PWM and other electronic converter technology to rectify the frequency AC, inverter, become a frequency controllable AC In the input to the motor, in the motor running through the V / F control, output torque control, vector control and other control methods to adjust the frequency, change the loop current, to achieve energy-saving operation, especially in the light load energy efficiency is obvious, An energy-saving products that have been widely promoted and applied

- Q: Laptop adapter

- The interface of the second adapter is the same as the first one And although the two numbers are not the same but the number of V on the line is the same as the interface

- Q: Three-phase asynchronous AC motor speed control method

- Second, the frequency control method Frequency control is to change the frequency of the motor stator power supply, thus changing its synchronous speed control method. Frequency converter system can be divided into AC - DC - AC inverter and AC - AC inverter two categories, most of the current domestic use - cross - frequency converter. Its characteristics: High efficiency, no additional loss during the speed control process; Wide range of applications, can be used for cage type asynchronous motor; Speed ??range, the characteristics of hard, high precision; Complex technology, high cost, maintenance and repair difficult. This method is suitable for applications requiring high precision and better speed performance.

- Q: I have a 11KW-4 pole inverter, now with the 4KW-4 pole motor, what impact?

- The inverter burns should be. Your motor overload is relatively large,

- Q: Variable frequency pump pressure in the very low flow instability, why?

- From the performance curve, the flow becomes smaller, the combination of pressure and frequency adjustment flow will only stabilize the flow at a small value, the pressure will be reduced, because the work point will move down.

- Q: Laptop power adapter output voltage is not the same as the current? What's the effect?

- I would like to elaborate on the basic principle of the large standard current power supply can replace the small standard current power supply. Some friends have misunderstood, that a large nominal current power will burn books, because the current big thing. In fact, how much current in the same voltage depends on the load, that is, the work of the books, when the books of high-load operation, the current larger, the books into the standby time, the current is smaller, in short, On the voltage divided by the equivalent resistance of the books. Large nominal current power supply has enough current margin, will not be replaced by a small standard current power supply after the overheating or output voltage is too low. On the contrary, with a small current power supply instead of high current power on the existence of the above risks. But some friends with 56w power supply instead of 72w with no problem, because the power adapter is usually designed to leave a certain margin, the load power should be less than the power supply,

- Q: Who knows how the inverter is calculated?

- Quadrupole motor synchronous speed is: 1500 r / min, but the actual motor speed will be more than 14 turn.

- Q: What is the difference between the collector and the emitter mode?

- The emitter is very high, the base is mixed and the collector is the lowest

- Q: 18: 5 kilowatts bipolar multi-pole pump motor with inverter

- Under normal circumstances, with 15KW inverter on it.

- Q: Three sets of batteries (540V) DC power supply U / f inverter.

- It is estimated that the battery should be string - and - series connection method, and then rectifier part of the converter (which may also be caused by the switch) is actually a series of diodes in series, positive and negative after the reverse is actually the battery is Negative shorts, resulting in burning, as to burn only one of the group of a few cells, it should be string - and - string and that group, because the parallel to bear it double voltage.

Send your message to us

Variable Frequency Drive 3.3KV 400KW Inverter

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords