V350 Series High Performance Vector Control ac Frequency Converter 50hz 60hz

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Single phase 220V,380V;

Vector control,

cost efficiency

small

Product Description

V350 series low-power closed-loop vector inverter

To satisfy the needs of equipment like machine tool, printing, textile and chemical fiber, V350 series inverter is designed on the basis of new hardware platform. Characterized by the excellent performance, compact structure, perfect protection function and various peripheral interface, V350 series inverter can be used for the secondary development in accordance with process

requirement in all kinds of field.

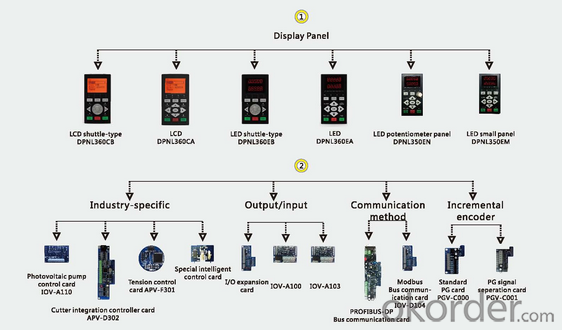

Basic function

Open/closed-loop vector control

Torque control

Motor parameter’s self-identification

Wobbling

Excessive current, voltage inhibition and low voltage inhibition

MODBUS/Profibus-DP communication

Synchronous communication linkage

Three-phase balance protection

Short circuit of protection

Function highlights

Setting simplification

One-click setting of common parameters

Virtual I/O port

Timer

Counter

Specifications

Input&output | Rated voltage/freq. | Three phase(4T****)380V 50/60Hz | Single phase(2S****) 220V~50/60 Hz |

Output voltage | 0~380V | 0~220V | |

Output freq | Low freq running mode:0.0~300.0 Hz. high freq running mode: 0.0~1000.0 Hz | ||

Digital input | V350-4T0030/2S0022 model below: standard five-way (DI), V350-4T0040 above:standard six-way(DI) | ||

Digital output | V350-4T0030/2S0022 model below: standard one-way (DO),V350-4T0040 model above: standard two-way DO | ||

Impulse input | 0.0~100.0K Hz impulse input, connect optional NPC OC output | ||

Impulse output | 0.0~100.0kHz impulse output NPC OC output available, support choosing PWM output method as the expansion analog output terminal | ||

Analog input | Standard configuration:0~10V voltage input(AI1), 0~20mA current input (AI2); standard expansion I/O card: -10V~10V voltage input | ||

Analog output | V350-4T0030/2S0022 model below: one-way 0~10V analog output signal ( optional 0~20 mA current output mode) V350-4T0040 above: two-way 0~10V analog output signal ( optional 0~20 mA current output mode)

| ||

Contactor output | Standard one pair of frequent open/closed AC 250V/2A contactor, allowing for expanding one to six pairs of contactors | ||

control characteristics | Control method | Close-loop vector control | Open-loop vector control | V/F control | |

Starting torque | 220% at zero speed | 200% at zero speed | 180% at zero speed | ||

Adjustment range | 1:1000 | 1:200 | 1:100 | ||

Speed stabilization accuracy | ±0.02% | ±0.2% | ±0.5% | ||

Torque control accuracy | ±5% | ±5% | — | ||

Torque response time | <5ms | <25ms | — | ||

Freq resolution ratio | Low freq running mode: 0.01 Hz: high freq running mode: 0.10 Hz | ||||

Freq accuracy | Low freq running:digital set—0.01Hz analog setting-the highest freq 0.1% High freq running: digital set-0.1 Hz, analog setting-the highest freq 0.1% | ||||

Loading capacity | 110% for long term; 150% for 60s, 180% for 2.5s; | ||||

Carrier freq | Three-phased voltage vector synthesis mode: 1.5~10.0 k Hz, two-phased voltage vector synthesis mode : 1.5~12.5 k Hz | ||||

Acceleration/deceleration time | 0.01~600.00Sec./ 0.01~600.0 Min | ||||

Magnetic flux brake | Increase the motor magnetic flux(30%~120% optional) to realize the fast brake for acceleration and deceleration | ||||

DC brake/ clasp brake | DC brake/clasp brake starting freq:0.0~upper rate limit, brake/clasp injection current 0.0~100.0% | ||||

Starting freq | 0.0~50.0Hz | ||||

Typical function | Multi-segment running | 16 freq/speed running, independent setting of direction, time acceleration and deceleration of each part, 7 PID setting |

Built-in PID | Built-in PID controller which can be used as external equipment | |

Sleep | Simple sleep and wake up function | |

MODBUS communication | Optional standard MODBUS communication protocol, flexible parameter reflexive function | |

Dynamic braking | Dynamic voltage: 650~760V, braking rate: 50~100% | |

General function | Failure restore, power to restart, motor parameter dynamic.static self detection, starting delay, current inhibit over voltage low voltage inhibit,V/F self defining curve |

Function highlights | Virtual I/O port | Eight-way virtual output/input port with no need to combine any external wiring to realize the complex application |

Synchronous communication linkage | Synchronous driving between different motors with no limit to communication linkage, freely choose linkage balance according to current, torque and power | |

Loading dynamic balance | Realize several motors’ dynamic balance and torque motor characteristics | |

Powerful starting torque | Support setting powerful starting torque in a certain time to deal with the load of large inertia and static friction | |

Priority setting | Freely choose prior sequence according to the freq, rotating speed setting channel, adjust to all kinds of field | |

Portfolio setting | More than one hundred of freq, rotating speed and torque | |

Timer | Three built-in timers: five kinds of clocks, five kinds of starting trigger mode,,several gated signal and working mode, seven output signal | |

Counter | Two built-in counters : the choose of clocks, four kinds of starting trigger mode, seven output signal | |

Macro parameter | Application macro: convenient to set several paris of fixed parameters and simplify the parameter set of general field | |

System macro: convenient to switch the working mode,such as the switchover between the high and low freq., and automatically define parts of parameter | ||

Parameter debugging | Any unsaved parameters in the spot can be saved, abandoned and restored into the original value | |

Parameter display | Automatically shield the parameters of unused module or selectively display the parameter altered, saved and changed |

Environment

Installation environment

Vertical installation with no direct sunshine, dust, corrosive and combustible gas, smoke and steam

Altitude

0~1000 meter . 10% reduced output current for each 1000 meter rise

Temperature

Working environment: -10°C~ +45°C storage environment: -20°C~ +60°C

Moisture

95% below (no frosting)

Vibration

<20m/s

FAQ

Q 1. what's the payment term?

A. We accept T/T, L/C, WEST UNION

Q 2. What's the delivery time ?

A. Normal model,0-3days,

For big order(more than 10,0000 usd),it takes about 7-15days. Customer make will be longer but with not over 15 days.

Q 3. What is the standard of package?

A. Export standard package or special package according to customer requirement

- Q: The relationship between the power supply of the notebook and the battery

- The relationship between the laptop power adapter and the battery should not be called a power supply relationship, both of which are devices that power the notebook host. The basic relationship between the power adapter, the battery, and the host is as follows:

- Q: What are the differences and links between the soft starters and the frequency converters, and their respective principles and uses?

- Soft starters and frequency converters are two completely different uses of the product. The frequency converter is used for the need for speed control where the output not only changes the voltage but also changes the frequency; the soft starter is actually a voltage regulator for the motor to start when the output only changes the voltage and does not change the frequency. The frequency converter has all the soft starter functions, but its price is much more expensive than the soft starter, the structure is much more complex. Soft starter (soft starter) is a set of motor soft start, soft stop, light load energy saving and a variety of protection functions in one of the new motor control device, known as the Soft Starter abroad. The softener uses a three-phase anti-parallel thyristor as a voltage regulator, which connects it between the power supply and the motor stator. This circuit, such as three-phase full-bridge rectifier circuit. When using the soft starter to start the motor, the output voltage of the thyristor gradually increases, the motor gradually accelerates until the thyristor is fully conductive, the motor works at the mechanical characteristics of the rated voltage, smooth start, reduce the starting current and avoid starting the overcurrent trip. When the motor reaches the rated speed, the start-up process ends, the soft starter automatically uses the bypass contactor to replace the completed thyristor, providing the rated voltage for the normal operation of the motor to reduce the heat loss of the thyristor and prolong the service life of the soft starter , To improve its efficiency, but also to avoid the harmonic pollution to the grid. Soft starter also provides soft stop function, soft stop and soft start the process of reverse, the voltage gradually reduced, the number of revolutions gradually reduced to zero, to avoid free-wheeling caused by the impact of torque. How the frequency converter works

- Q: On the notebook power adapter output current and voltage issues

- This current is the maximum current value of the adapter output, Voltage matching, of course, can be charged. It is recommended to select an adapter with an output current value that is slightly larger than the original.

- Q: My motor is a low frequency 8 pole motor, about 80W. I would like to choose a frequency converter

- Poor match, the program is unreasonable Current 1.5A, choose a single-phase 220v power supply, 370-500w inverter it

- Q: What is the principle and implementation of the inverter?

- How the inverter works: 1. DC can be converted into alternating current through the oscillation circuit 2. The resulting AC power is then boosted by the coil (in this case, the alternating current of the square wave) 3. Rectify the resulting alternating current to obtain a sine wave

- Q: Do you need to rectify before switching?

- There are two ways to convert frequency, that is, cross and cross the intersection, the latter need a direct current, need no rectification, depending on your DC situation.

- Q: Old printing machine transformation, 37KW6 polar frequency motor with brake, inverter 55KW, now found running,

- May be mechanical part of the card, try idling motor.

- Q: Inverter principle eff23

- The basic principle of the inverter The inverter is a device that converts the power frequency (50Hz or 60Hz) into AC power of various frequencies to realize the variable speed operation of the motor. The control circuit completes the control of the main circuit, and the rectifier circuit converts the alternating current into direct current and DC Circuit rectifier circuit output smooth filter, the inverter circuit will reverse into the DC power.

- Q: Three-phase two-pole motor can be used to reduce the frequency of the inverter

- Speed range adjustable, you can drop to any speed you want!

- Q: How to make the motor speed (control speed), can not use frequency

- In general, the torque generated by the motor is reduced with decreasing frequency (decrease in speed), and the reduced actual data is given in some frequency converter manuals. By using the flux vector control of the inverter, will improve the motor at low speed torque, even in the low speed area motor can also output enough torque. When the frequency converter to speed up to 60Hz frequency, the motor output torque will reduce the normal motor is designed to 50Hz (60Hz) voltage, the rated torque is given in this voltage range. So the rated frequency under the speed is called constant torque speed, the inverter output frequency is greater than 50Hz frequency, the motor torque to be inversely proportional to the frequency of the relationship between the decline. When the motor is running at a frequency greater than 60 Hz, the magnitude of the motor load must be taken into account to prevent the motor output torque from being insufficient. For example, when the torque generated by the motor at 100 Hz is about to be reduced to about 50 Hz, the torque is generated. So the rated frequency above the speed is called constant power speed.

Send your message to us

V350 Series High Performance Vector Control ac Frequency Converter 50hz 60hz

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords