Tower Crane TC7135 Construction Equipment Building Machinery Sales

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tower Crane TC7135 Description:

1.CMAX Tower Crane TC7135 is one of the main product of CNBM company, which have competitive price and excellent quality, suitable for all kinds of construction project and can work under all kinds of work condition.

2. Tower Crane TC7135 can adopts standard section hydraulic lifting and connecting, and can decide the crane height according to the actual height of the building, and at the same time the lifting capacity will not be affected.

3. Tower Crane TC7135 has high working speed, good speed-adjusting performance, steady operation and high efficiency. Three-speed motor and mono-speed ratio decelerator are applied in the lifting struction, which enables heavy load low speed and light load high speed.

4.Tower Crane TC7135 has complete set of safety devices, which can guarantee the safe and high efficienct operation of the equipment. The machine is equipped with lifting height limiter, dolly range-change limiter, moment limiter,weightlimiter,circumgyrating limiter,and so on.

5.Tower Crane TC7135 has scientific layout and beautiful appearance. The operator's room is set independently on one side, with good vision field. It creates a good working environment for the operato.

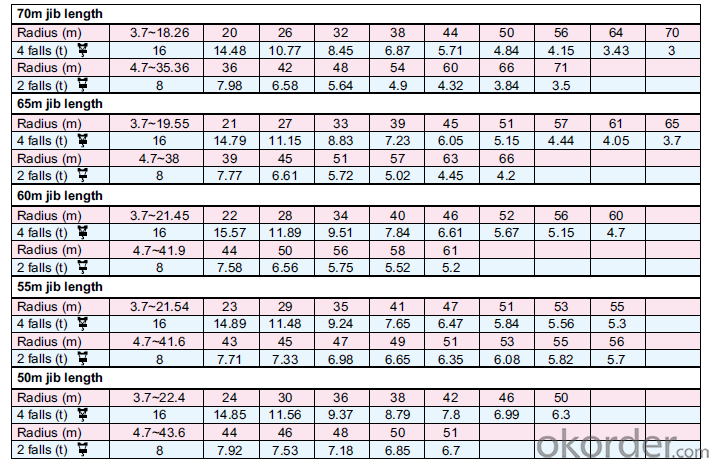

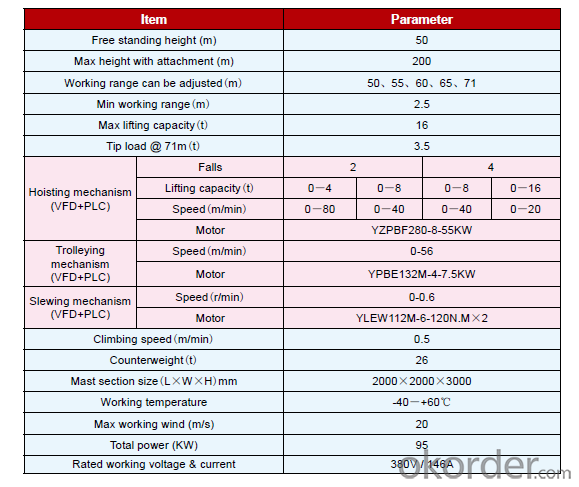

Tower Crane TC7135 Parameter:

Max. working range 71m, tip lifting weight 3.5T and Max. lifting weight 16T.

Hoisting mechanism fitted with three speed motor, stable braking and less shock when shifting.

Trolleying mechanism can provide two operation speeds.

Free standing height (m) 50

Max height with attachment (m) 200

Working range can be adjusted (m) 50、55、60、65、71

Min working range (m) 2.5

Max lifting capacity (t) 16

Tip load @ 50m (t) 3.5

Tower Crane TC7135 Packaging & Delivery:

40HQ container

20~25days after deposit

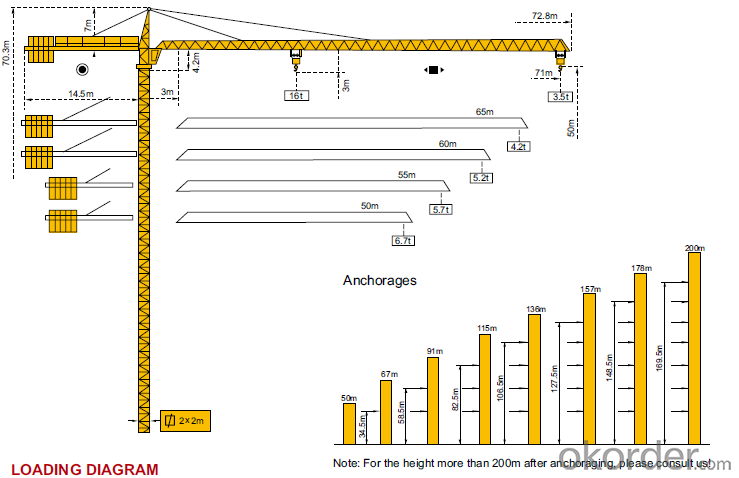

Tower Crane TC7135 Diagram:

Tower Crane TC7135 Technical Sheet:

Tower Crane TC7135 FAQ:

1.What is tower crane?

Tower crane is a modern form of balance crane that consist of the same basic parts. Fixed to the ground on a concrete foundation (and sometimes attached to the sides of structures as well), tower cranes often give the best combination of height and lifting capacity and are used in the construction site.

2. What is the meaning of the tower crane’s code?

Take Tower Crane TC7135 for example, the first two letters “TC” means Tower Crane, “71”means jib length is 71 meter, and the last two letter “35” means the tip load is :3.5 ton.

3. What is the principal to quote the right tower crane to the client?

First, we need to know clients’ requirements,for example, max lifting capacity, height, tip load and jib length.. Second, we need to know what the foundation requirement from the client is and Third if there are special needs. CNBM could suggest proposal according to clear data provided by the clients.

- Q: Construction Engineering, moving equipment and stationary equipment, respectively

- 1, moving equipment refers to the rotating device driven by the drive (that is, energy consumption of equipment), such as pumps, compressors, fans, etc., the energy can be electric power, pneumatic power, steam power, etc..

- Q: Where was the construction machinery conference held in 2015?

- Organizer: China Academy of machinery science and engineering machinery and military modified vehicle testing center, Shandong Bada International Engineering Machinery Company Limited, Shandong Bada Luqiao Construction Co. Ltd. and Shandong northern Luqiao Engineering Company Limited. Organizer: Shandong Bada international engineering machinery City, Lee brothers auction, Beijing Shengda Trade Center, Hing Beijing power machinery and equipment in the international science and Technology Co Ltd

- Q: Changsha Sanlian Building Machinery Fittings Factory

- The company in Changsha Hongdun business online can not find, provided by his address: two Changsha section of Xingsha Economic Development Zone Yuan Ming Road, I checked 114 specially call 12580 to booking the hotel near the road, not the road. Definitely a liar.

- Q: What is equipment manufacturing and machinery manufacturing? What's the difference between them?

- Major technical equipment refers to the technical difficulty in equipment manufacturing, complete and strong, is of great significance, has a significant impact on the national economy need to be beneficial to the people's livelihood, complete sets of major technical equipment organizations across sectors, industries and regions to complete.

- Q: What is the use of spare parts prices in Chinese market by foreign companies?

- But there is always somebody to ask, just like a college paper, where everyone can read or keep secrets, but collecting them and sending them to foreigners is a sign of treason

- Q: How do the welding parts in the welding drawings of the machine parts indicate the technical requirements of the drawings?

- Therefore, the medium carbon steel has the most extensive application in the medium strength level. Besides being used as building material, it is widely used in the manufacture of various mechanical parts. Welding: 1 the preheating is conducive to reducing carbon steel heat affected zone is the most

- Q: China mechanical net

- There are mechanical product development and design, mechanical equipment transformation, mechanical equipment maintenance, data inquiries, standard inquiries, mechanical professional translation, mechanical CAD and other mechanical and technical services.

- Q: Where are the hanging baskets for the building?

- It is forbidden to take a stool or put a ladder on a hanging basket to work higher; it is not allowed to work alone in a basket, and no electric machinery or equipment can be placed in the basket;

- Q: What are the construction materials, components, fittings and equipment in construction?

- 3. Equipment: a complete device which belongs to the unique function of each function of the construction project. There are systems, equipment and conventional equipment, such as: elevator, automatic fare collection, HVAC, gas fire protection, etc..

- Q: What are the sub projects of a construction project?

- Appendix B Construction Engineering Division (sub branch) engineering, sub project division, B.0.1 Construction Engineering Division (sub branch), engineering, sub projects can be divided into table B.0.1. Table B.0.1 division number of construction works, sub works and sub projects

Send your message to us

Tower Crane TC7135 Construction Equipment Building Machinery Sales

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords