Tencate Mirafi Geogrids 50/50kn/m Warp Knitted Fiberglass Geogrid in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

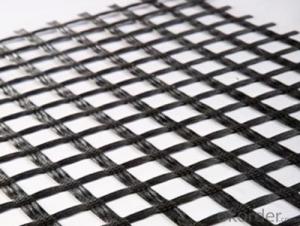

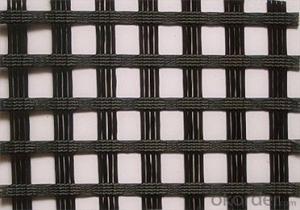

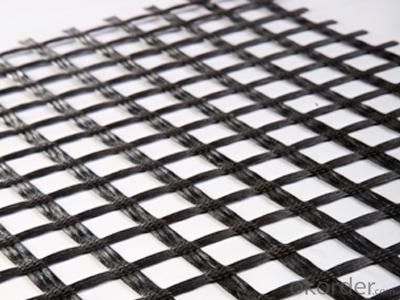

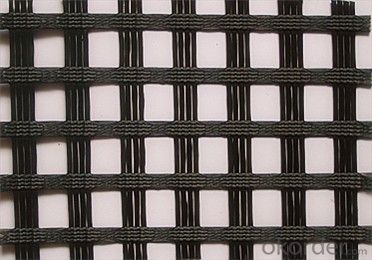

Structure of 50/50Kn/M Warp Knitted Fiberglass Geogrid:

Warp Knitted Fiberglass Geogrid is to select high quality enhanced non-alkali fiberglass yarn,and it uses foreign advanced warp knitting woven to become the base materials.Using the warp knitting oriented structure to make full use of the fabric yam strength and improve its mechanical properties ,so it makes good tensile strength ,tearing strength and resistance to creep properties of modified asphalt,and through high quality coating is handled and become planar finely materials.

Main Features of 50/50Kn/M Warp Knitted Fiberglass Geogrid:

fiberglass geogrid for soil reinforcement

fiberglass geogrid

High intension,high tenacity,high occlusive force with soil or gravel,erosion-resistant,water drainage,light weigth.

Reinforce soft soil roadbed,rib side slope of embankment,enhance isolation,inhibit ground deformation,prevent crack by reflection,incre

High tensile strength, low elongation

High stability

Warp Knitted Fiberglass Geogrid Images

Warp Knitted Fiberglass Geogrid specifiction

Glass Fiber Geogrid GGF80 Technical Specification | |||

Property | Test Method | Unit | Index |

Wide Width Tensile Strength | |||

MD | KN/M | ≥80 | |

CMD | KN/M | ≥80 | |

Elongation At Break | ≤4 | ||

Grid | MM | 25.4×25.4 | |

Width | M | 1~6 | |

Packaging | Details | ||

Roll Dimensions(W×L) | According to customer requirements | ||

Square Meters Per Roll | |||

Estimated Roll Weight | |||

It is widely used in Asphalt wall, railway foundation, dike slope, runway and sand harnessing.

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Can geogrids be used in reinforcement of stormwater management systems?

- Yes, geogrids can be used in the reinforcement of stormwater management systems. Geogrids are commonly employed to enhance the stability and strength of soil structures, such as retaining walls, slopes, and embankments. In stormwater management systems, they can be utilized to reinforce the base and sidewalls of stormwater ponds, channels, and underground storage systems. This reinforcement helps to prevent soil erosion, maintain structural integrity, and improve overall performance of the stormwater management system.

- Q: Are geogrids compatible with different soil types?

- Yes, geogrids are generally compatible with different soil types. Geogrids are versatile materials that can be used with various soil types, including clay, sand, and gravel. They are designed to provide reinforcement and stability to the soil, improving its load-bearing capacity and preventing erosion. However, the specific type and design of the geogrid may vary depending on the soil characteristics and engineering requirements of the project.

- Q: How are geogrids used in civil engineering?

- Geogrids are used in civil engineering to reinforce and stabilize soil structures. They are typically made of high-strength polymer materials and are placed within the soil to provide additional strength and stability. Geogrids help distribute loads, prevent soil erosion, and improve the overall performance of infrastructure projects like roads, retaining walls, and embankments.

- Q: How do geogrids help in reducing construction costs?

- Geogrids help in reducing construction costs by providing reinforcement to soil and improving its stability, which eliminates the need for expensive excavation and replacement of weak soil. They also allow for the use of less expensive and locally available fill materials, reducing the need for transportation and disposal costs. Additionally, geogrids help in the construction of thinner and lighter structures, reducing the amount of expensive construction materials required.

- Q: What are the design considerations for geogrid-reinforced pavements?

- Some design considerations for geogrid-reinforced pavements include the selection of appropriate geogrid material and properties, determining the optimal geogrid placement and spacing, considering the load-bearing capacity and traffic requirements of the pavement, accounting for soil properties and stability, and ensuring proper installation and maintenance procedures. These considerations are important for achieving a durable and cost-effective geogrid-reinforced pavement system.

- Q: What is the recommended spacing between geogrid layers?

- The recommended spacing between geogrid layers can vary depending on the specific application and design requirements. However, in general, a spacing of about 1 to 2 feet (30 to 60 centimeters) is often recommended. This allows for proper interlocking and interaction between the geogrid layers, ensuring optimal load distribution and stability. It is important to consult with a geotechnical engineer or follow the manufacturer's guidelines to determine the appropriate spacing for a particular project.

- Q: What is the effect of installation spacing on geogrid behavior?

- The effect of installation spacing on geogrid behavior is that it influences the overall performance and effectiveness of the geogrid in reinforcing soil. The spacing between individual geogrids affects their ability to distribute loads evenly, provide adequate confinement to the soil particles, and enhance interlocking mechanisms. Proper installation spacing ensures optimal stress distribution, reduces differential settlement, and improves overall stability and load-bearing capacity of the reinforced soil structure.

- Q: How many Chinese geogrid manufacturers? How many famous

- Geogrid is also divided into many types, the structure of glass fiber, plastic, steel, polyester and so on; materials are divided into polypropylene, polyvinyl chloride, polyethylene, etc.; the form of two-way, one-way, triangular, etc....

- Q: How do geogrids help in reducing the environmental impact of construction?

- Geogrids help in reducing the environmental impact of construction by providing stabilization and reinforcement to the soil, leading to a reduction in the amount of excavation and land disturbance required. This helps to minimize the need for additional resources and materials, as well as the overall carbon footprint of the construction project. Additionally, geogrids can enhance the longevity of structures, reducing the need for frequent repairs or replacements, further minimizing the environmental impact.

- Q: Can geogrids be used in coastal protection?

- Yes, geogrids can be used in coastal protection. Geogrids are commonly used in erosion control and stabilization projects, including coastal areas. They provide reinforcement to soil and help prevent erosion by increasing the overall stability of the coastline. Geogrids can be used in various coastal protection applications such as retaining walls, revetments, and slope stabilization, helping to mitigate the impact of waves, tides, and currents.

Send your message to us

Tencate Mirafi Geogrids 50/50kn/m Warp Knitted Fiberglass Geogrid in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords