Solar Water Pump System 0.1KW-37KW for Agricultural Irrigation/ Helen

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

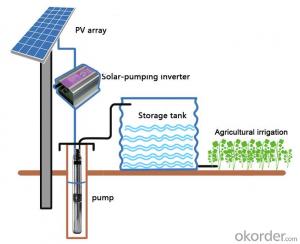

The photovoltaic pumping system is different from the traditional AC pumping system , and the photovoltaic pumping system utilizes solar cells convert solar energy into electric energy , then the photovoltaic pumping inverter drives ac motor for the pump running , and pumping up water from water well , river , lake etc areas and then transport to the destination to satisfy our requests for the water demand .

Photovoltaic arrays adopts solar radiation energy to convert it to electric power ,providing the motive power for the whole system . And the function of the solar pumping inverter is converting the DC power output from PV array to AC power to drive the pump to finalize the water pumping up as well as adjusting the output power real-timely according to the change of sunlight intensity , in this way , the system realizes the max power point tracking and the solar energy can be utilized furthest

The whole system solves the water pumping up requests perfectly , omitting the battery bank and charge controller etc equipments , so it is very economical and environmental . Since they are with the merits of low carbon , energy conversation , environmental protection etc , so they have a broad market foreground and great social value

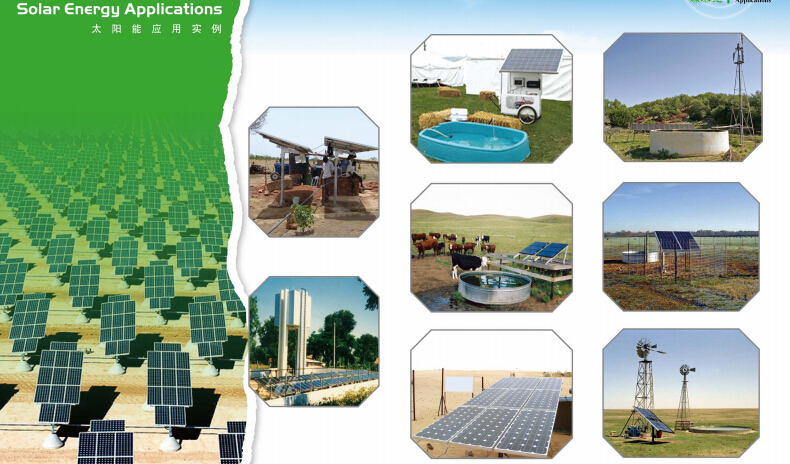

2.2 Application

Agricultural irrigation

Desert manage

Domestic water

Grassland animal husbandry

city waterscape

Island water supply

Landscape and fountain system of municipal engineering , city square , hotels and residence community

2.3 About product

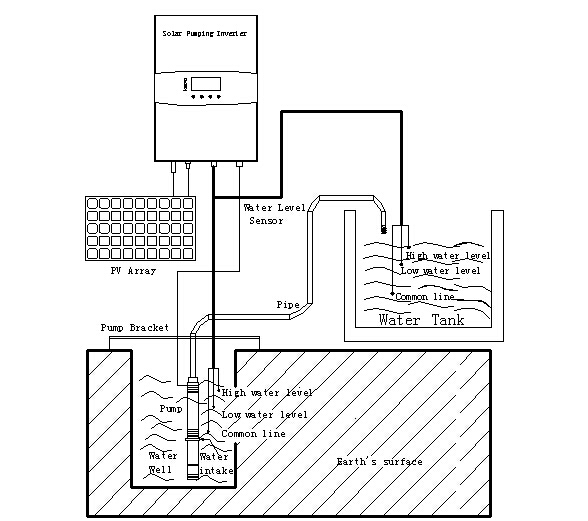

This product is using a high performance digital signal processing chip, can provide solution for solar water pumpingsystem with high cost performance. Solar pumping system as a whole block diagram as shown in 2.

SHP series inverter has the following features:

a. True max power tracking technology (TMPPT) with our own intellectual property; effectively improve the use ratio of PV array. The stable tracking efficiency can reach 99.2% , Solving the problem of bad tracking efficiency and running unstability under the situation of sunlight intensity quick change when comparing with the traditional MPPT method .

b. Adopt efficient IPM power module from Mitsubishi Company with high reliability.

c. With the function of high and low water level detection , high safety factor.

d. Automatic anti-drying protection function , with multi-protection for motor

e. Multi-language LCD display , easy for operation , very user-friendly

f. The independent developed principal computer with our own intellectual properties , remote monitoring is available

g. Modular design , direct plug-in terminal , good-looking appearance, easy for installation , operation and maintenance .

h. Suitable for the pump adopted three phase asynchronous motor

i. Complete digital control , with the function of full automatic running and data storage .

j. Perfect protection system , with the protection function for lighting , over voltage , under voltage , short circuit , over loads , water drain off , low sunlight , over heating etc ,

k. Adopt the complete radiating system , so radiating efficiency is better and the service life is longer

l. Through strict environmental test , adapt the rigorous environment :-10℃~+50℃

m.No impacted mains supply power switch function (optional ), All-weather running available

n. Through strict environmental test , adapt the rigorous environment :-10℃~+50℃

- Q: Can a solar pump be used in areas with high levels of nitrites in the water?

- Yes, a solar pump can be used in areas with high levels of nitrites in the water. Nitrites in the water do not directly affect the functionality of a solar pump. However, it is important to note that high nitrite levels can potentially have negative impacts on the overall water quality and may require additional treatment or filtration measures to ensure safe and efficient operation of the solar pump system.

- Q: Can a solar pump be used for fountain installations?

- Yes, a solar pump can be used for fountain installations. Solar pumps are designed to be energy-efficient and operate using solar power, making them an environmentally-friendly choice for fountains. They work by converting sunlight into electricity, which powers the pump to circulate water within the fountain. Solar pumps are typically easy to install, require minimal maintenance, and can be used in both small and large fountain installations. Additionally, they do not require a direct electrical connection, eliminating the need for wiring or the use of electricity from the grid. Overall, a solar pump is a great option for those looking to power their fountain installation with renewable energy.

- Q: How does a solar pump help in reducing the use of irrigation water?

- A solar pump helps in reducing the use of irrigation water by using solar energy to power the pump, eliminating the need for electricity or fuel. This makes it a sustainable and cost-effective solution for farmers and agricultural practices. Additionally, solar pumps can be set up in remote areas without access to electricity, enabling efficient irrigation and reducing dependence on traditional irrigation methods that consume more water.

- Q: Are there any environmental benefits of using a solar pump?

- Using solar pumps has numerous environmental advantages. Firstly, these pumps rely solely on renewable energy from the sun, eliminating the need for fossil fuels and greatly reducing greenhouse gas emissions, air pollution, and dependence on non-renewable energy sources. This not only helps combat climate change but also improves air quality. Secondly, solar pumps operate without consuming any water or natural resources. They utilize solar panels to convert sunlight into electricity, enabling the pump to extract water from underground or surface sources. This sustainable approach to water pumping ensures the conservation of water resources, making them available for various other purposes like agriculture, sanitation, and drinking water. Moreover, solar pumps prove to be highly beneficial for irrigation in agriculture. By harnessing solar power for irrigation, farmers can decrease their reliance on non-renewable energy sources such as diesel generators or electric pumps. This leads to a substantial reduction in carbon emissions and encourages the adoption of sustainable agricultural practices. Furthermore, solar pumps are particularly advantageous in remote areas with limited or no access to electricity. In these locations, solar pumps not only provide a clean and dependable water source but also eliminate the need for expensive and environmentally harmful alternatives like diesel-powered generators or the transportation of fuel for traditional pumps. In conclusion, the utilization of solar pumps offers diverse environmental benefits, including the reduction of greenhouse gas emissions, air pollution, and water consumption. Additionally, solar pumps promote sustainable agriculture and provide clean water in remote areas.

- Q: Can solar pumps be used for water supply in remote oil or gas exploration sites?

- Yes, solar pumps can be used for water supply in remote oil or gas exploration sites. Solar pumps are a sustainable and cost-effective solution that can operate independently from the grid, making them ideal for remote locations. They can effectively pump and supply water for various purposes such as drilling operations, equipment cooling, and personnel needs at these sites. Additionally, the use of solar pumps reduces the reliance on fossil fuels, minimizing the environmental impact associated with traditional water pumping methods.

- Q: Can a solar pump be used for vineyard irrigation?

- Certainly, vineyard irrigation can indeed utilize a solar pump. When it comes to supplying water to vineyards, solar pumps offer both sustainability and affordability. By harnessing solar energy to operate the pump, there is no longer a requirement for electricity or fuel. Solar pumps possess the ability to extract water from wells or other water sources and transport it to the vineyard, enabling efficient irrigation practices. What's more, the installation and maintenance of solar pumps are hassle-free, making them an exceptionally convenient option for vineyard proprietors.

- Q: Are there any specific installation requirements for a solar pump system?

- Yes, there are specific installation requirements for a solar pump system. These requirements include finding a suitable location with ample sunlight exposure, ensuring proper alignment and tilt angle of solar panels, installing a stable and secure mounting structure, connecting the pump to the solar panels with appropriate wiring, and considering the depth and type of water source for the pump's installation. It is also important to follow manufacturer guidelines and local regulations while installing a solar pump system.

- Q: Can solar pumps be used for irrigation?

- Yes, solar pumps can be used for irrigation. They are an efficient and sustainable alternative to traditional diesel or electric pumps, as they harness solar energy to power the pump and provide water for irrigation purposes. Solar pumps are particularly useful in remote areas where access to electricity is limited, and they offer cost savings on fuel and maintenance.

- Q: Does the efficiency of a solar pump decrease over time?

- Yes, the efficiency of a solar pump can decrease over time due to various factors such as wear and tear, aging of components, and accumulation of dirt or debris. Regular maintenance and cleaning can help mitigate this decrease in efficiency and ensure optimal performance.

- Q: Can a solar pump be used for water treatment systems?

- Yes, a solar pump can be used for water treatment systems. Solar pumps are commonly used in water treatment systems as they provide a sustainable and environmentally friendly solution. They can effectively pump water from various sources such as wells, rivers, or lakes, which can then be treated for purification purposes. The use of solar energy to power the pump reduces dependency on electricity grids and minimizes operational costs, making it a feasible option for water treatment systems in remote areas.

Send your message to us

Solar Water Pump System 0.1KW-37KW for Agricultural Irrigation/ Helen

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords