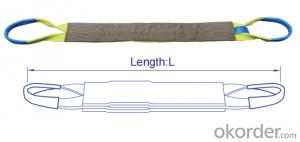

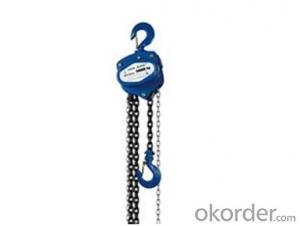

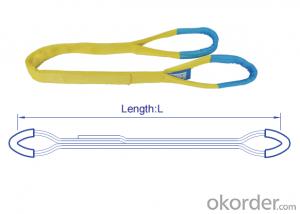

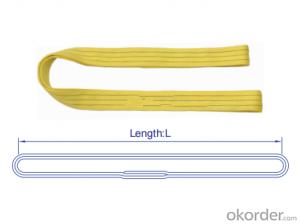

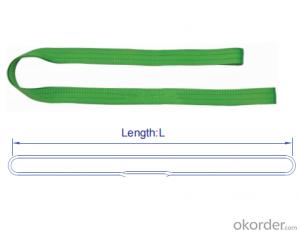

Soft Wide Body Polyester Webbing Textle Sling Working Load 12T

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

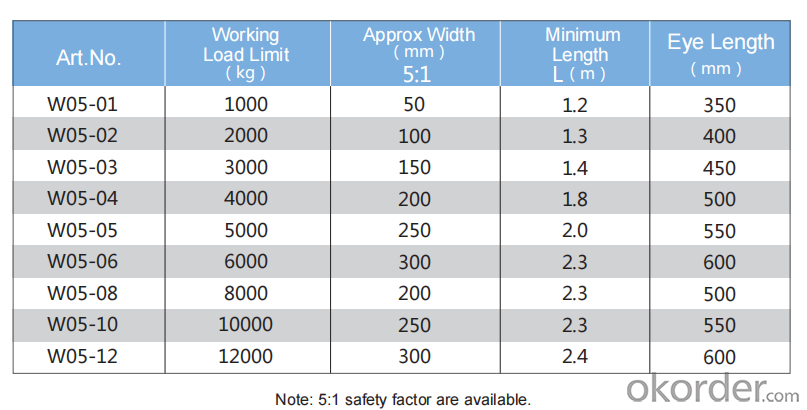

Specification

Soft Wide Body Polyester Webbing Textle Sling Working Load 12T

Chracteristics:

Soft, light, no harm to the cargo, safety, long life and so on.

Light and soft, can be used in small narrow space.In PU processing, anti-abrasion is enhanced,Non-conductive, no danger of electric stroke.

Product usage :

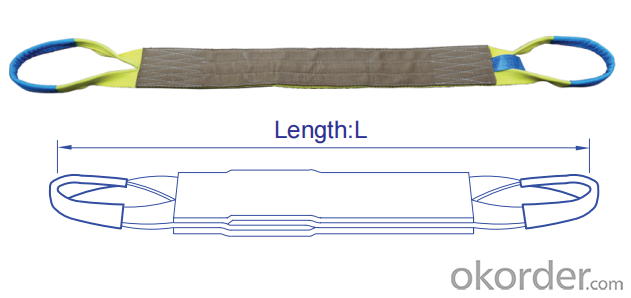

Apply to oil pipelines, large diameter thin-walled pipe and products hoisting.

Textile slings are widely used for lifting, pulling, bundling, fixed and other operations in machining, port handling, marine engineering, ship, electric power, transportation, erospace and other fields.

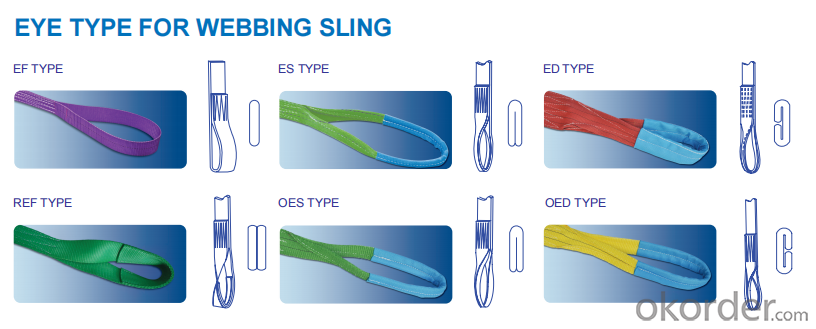

More Type:

Company Profile:

We are able to manufacture special slings such as high-strength type, flame retardant type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant type, fluorescent type, optical inspection type and oil and water resistant type sling.

Shipping:

1.Selling Units:Single item

2.Single package size: 30X4X5 cm

3.Single gross weight:5 kg

4.Package Type:Shrink-packaging + Carton Box + Pallet

Certificate:

- Q: What are the connections and differences between hooks, slings, rings and heavy truck rings in cranes? What are the hoisting designs?

- Round nylon lifting rope series: no connecting nylon lifting rope, two button nylon lifting rope, multi nylon lifting rope and shipAnchor rope, rope, paper rope, lifting rope, all kinds of transformer braided rope.

- Q: Is rope sling good business and high profit?

- With an annual output of 1 million 800 thousand tons of steel China ranked first in the world, is the first world phosphating wire rope wire rope surface treatment inhibited fretting fatigue to prolong the useful life (fatigue life), business wire rope and rigging, ordinary product profit, if can be linked to the manganese phosphating coating of steel wire rope, the profit is very high

- Q: 20 tons sling rope, steel wire or chain?

- The main - phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope and coated steel wire rope wire rope varieties, for reference only

- Q: Requirements and matters needing attention in hoisting

- When the equipment is mounted on a frame or a building, its strength and stability shall meet the requirements of the installation conditions. In equipment installation and location according to the requirements of the drawings are tightly connected or welded, meet the design requirements of the strength and has stability, can be decoupled, otherwise they should be temporary fixed 1. security measures, to prevent the crane from tilting measures (1). The lifting scene road must be smooth solid backfill, soft soil should be processed. If the soil is soft, roads should be paved separately. Parking crane is not working on a slope, also does not allow the crane two side high.

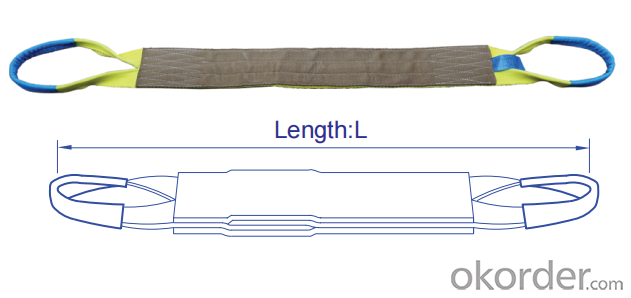

- Q: They are used for slings, ropes, chains, suspenders, hand hoists, right?

- A variety of commonly used wire rope phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope.

- Q: The wire rope lock can hang a lot of things

- The crane used in atmospheric environment, preferably manganese phosphide coating, steel wire rope, heavy corrosive environment, preferred hot-dip galvanized double phosphating steel wire rope, priority wire rope in sea water. Please note that at the time of purchase, in the purchase invoice must indicate the name of wire rope, such as phosphate coated wire rope or 316 stainless steel wire rope, to protect their legitimate rights and interests, in addition, patent products are generally in the rope on the outer packing of a patent spraying label, warranty should be the main technical indicators, such as the type of phosphating film and film, for reference

- Q: What are the selection principles for lifting cranes?

- To avoid the use of large lifting capacity of the crane lifting capacity of small parts, small crane overload lifting component, or choose not modified after the actual loading test of crane hoisting, shift or use the high cost of equipment.

- Q: What are the installation steps for crane beams?

- Installation of crane beam elevation as a negative deviation, between surface and column bracket crane beam flange into the iron plate. But the shim shall not exceed three layers and shall be placed under the end of the crane beam or under the stiffener, and the area of the shim shall not be less than 60% of the part of the contact area between the crane beam and the bracket.

- Q: Why are the suspension bridges a main cable, even a n multi sling, not a bridge directly from the tower?

- Finally, the gravity of the main beam becomes the two vertical force of the tower, so that the force passes to the pier under the tower.There are more cables, and the same reason. There are a lot of bars, that's to distract the main girder from the cables.As a kind of cable of cable-stayed bridge, more than beam bridge spanning capacity is the main bridge of long span bridges. The cable stayed bridge is composed of many cables which are directly connected to the tower. The cable-stayed bridge is composed of pylon, main beam and stay cable. The types of pylon are A, inverted Y, H and single column. The materials are steel and concrete. There are single cable plane, parallel double cable plane and inclined cable plane in the stay cable. The first modern cable-stayed bridge was built in Sweden in 1955 and has a span of 182 meters. At present, the largest span cable-stayed bridge built in the world is the Normandy bridge in France, with a main span of 856 meters. The Shanghai Yangpu bridge, built in 1993, is the largest cable-stayed bridge in China, with a main span of 602 meters

- Q: What are the specifications for the rigging?

- The wire rope for the first time in the field of fretting fatigue control measures is the phosphating coating steel wire rope patent technology production, steel wire after manganese phosphating or zinc manganese wear-resistant steel wire surface treatment, corrosion resistance to enhance, not easy to wear and corrosion fatigue life of the steel wire rope large increase, fatigue life is three as structure of plain steel wire rope, the highest value of contrast test has reached an alarming four times, can be verified by fatigue test, fatigue test machine if they have on their own to do comparative tests, this test results most credible, the service life of wire rope and the fatigue life is directly proportional to the fatigue life, long service life with the proportion of prolonged use of lower cost, better stability, phosphating coating of steel wire rope is patent technology production

Send your message to us

Soft Wide Body Polyester Webbing Textle Sling Working Load 12T

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches