Single Component SPU Waterproof Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Component Polyurethane Waterproof Coating Introduction

Single-component moisture-curing pure polyurethane waterproof coating is a kind of liquid polymer waterproof material,

suitable for dry and wet base surface construction, solidified into tough and elastic, non-toxic and tasteless waterproof

film after coating. It is a new type of environmental friendly waterproof material without solvent.

Single Component Polyurethane Waterproof Coating Application

•Building roof

•Concrete

•Wall

•Water Tank Structure

•Floor(kitchen floor, bathroom floor ect)

•Underground Tunnel

•Sewerage Structure

•Movement Joint

•Wet Area, Pipes, Sewer & etc.

Single Component Polyurethane Waterproof Coating Advantage

1.water based and solvent based

2.Solid content above 80%

3.Durable performance, UV resistant, ageing-resistant,resistant high and low temperature,antifatigue, withstand constant immersion in water

4.Good splicing performance

5.Operate conveniently, low viscosity

6.Can splicing with concrete and many kinds board stuff

7.Will not change color after used

8.Apply for Roof,Swimming Pool,Tank and more

Single Component Polyurethane Waterproof Coating Specifications

NO. | Items | Ⅰ | Ⅱ |

1 | Tensile Strength MPa≥ | 1.9 | 2.45 |

2 | Elongation at Break %≥ | 550 | 450 |

3 | Tearing Strength N/mm≥ | 12 | 14 |

4 | Bend at Low Temperature°C≤ | -40 | |

5 | Unpermeability0.3MPa 30min | Impermeable | |

6 | Solids Content%≥ | 80 | |

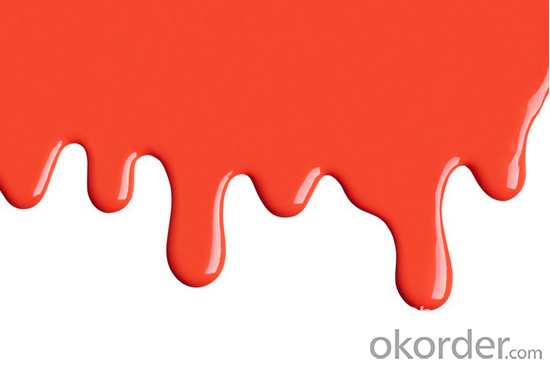

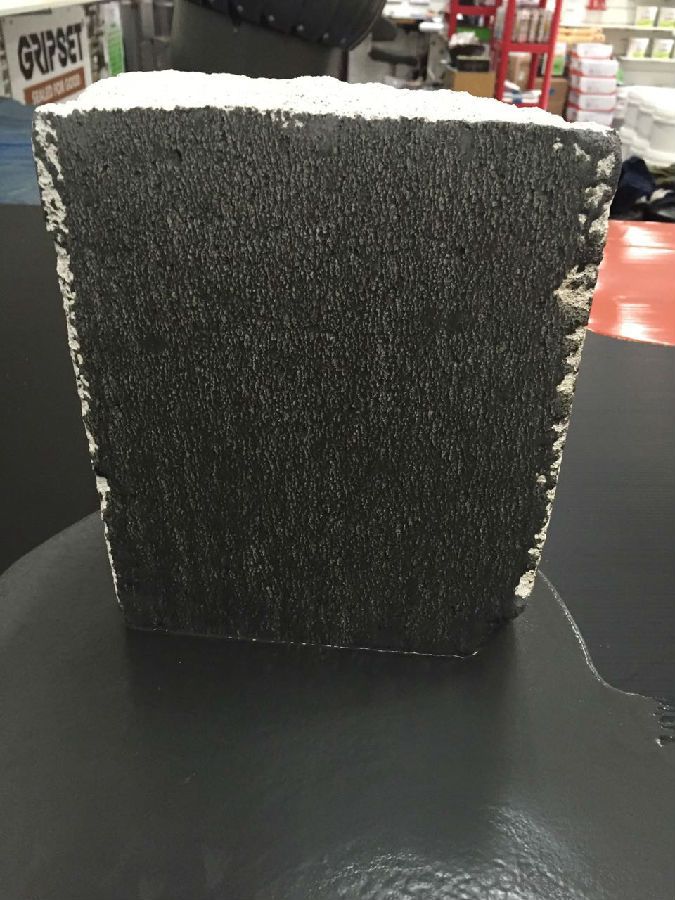

Single Component Polyurethane Waterproof Coating photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: A complete set of basement waterproof construction program

- First, the basement of the external walls of water leakage project engineering basement waterproofing standard GB50108-2001 "underground engineering waterproof technical specifications" secondary waterproof rating. Basement exterior wall waterproof structure with self-waterproof concrete plus coil waterproof, 50 thick polystyrene board protective layer.

- Q: Home improvement waterproofing problem

- 2, the ground waterproof layer generally turned 20 cm. Use the shower parts generally do more than 2.2 meters.

- Q: What is the price of a waterproof window cover?

- 3, decorative panels Decorative panels are divided into paint-free panels and paint panels. Currently on the market, there are many window-free products, paint-free board is 5 mm density, the board pressure a layer of thin layer of color paper, due to the type of color paper, so there can be a lot of paint-free Color. Paint decorative panel is the surface of a layer of veneer plywood, there are many types, different wood has different colors. The benefits of window sets

- Q: Can Henkel have water against him?

- Add a small amount of water is possible because the premise of waterproofing should also be wet before the grassroots

- Q: Js waterproof coating without powder can brushing

- 4. Coating protection: JS waterproof coating after the end of the construction, not thoroughly dry before the need to protect the coating, including the suppression of pedestrians, rain erosion, exposure, sharp damage to objects; thoroughly dry solid JS cement Emulsion coating does not need to do other protective layer;

- Q: Roof leakage, what materials do the best waterproof

- First, the roof leak to find the first leak, looking for the main leak from the roof to the lower to find leakage. The first is to see if there is no cracks in the roof, the original waterproof layer is not aging, the roof of the original SBS waterproofing membrane has no bubbles, there are bubbles to prove that the water has entered the bottom of the waterproof layer, and thus leaking. There is a block on the roof of the gutter is not blocked in the countryside, there are still a large number of tile-roofed house, when the tiles due to damage caused by the roof leakage, as long as the replacement of tiles can be, this step is also known as "

- Q: Roof for the insulation, Master roof, using two waterproof construction program

- Fourth, the finished product protection 1, has been laid the membrane waterproof layer, should be taken to protect the facilities, is strictly prohibited in the waterproof layer on the construction operations and transportation, and should be timely to do the protective layer of the waterproof layer. 2, through the roof, wall waterproof layer at the pipeline, construction and after the completion of damage shall not damage. 3, deformation joints, water, etc., before the construction of waterproof layer, should be temporary closure, waterproof layer is completed, should be cleared to ensure that the tube, sewn smooth, to meet the use of function. 4, roof construction shall not pollute the walls, cornices and other finished products.

- Q: What should you pay attention to before the construction of the basement waterproofing membrane?

- Plastic runway construction should pay attention to: 1, before the construction, must be on the asphalt concrete foundation for quality acceptance, acceptance criteria according to design standards and technical specifications, the plastic runway in the corresponding drainage facilities, can be used around the clock. The ambient temperature should be controlled at 5 ℃ ~ 38 ℃, to avoid below 5 ℃, 38 ℃ above the ambient temperature operation, the relative humidity control below 70%, the foundation requires a clean, according to the temperature and relative humidity to adjust the amount of catalyst The curing speed control appropriate. Color paste and prepolymer storage, the lid to be tightened, before use to detect moisture, qualified after use, the water in the foundation should also be controlled to avoid the bubble after the glue. Plastic pavement materials must be carefully checked when the quality inspection certificate and validity period.

- Q: Why should the use of high pressure perfusion waterproof plugging method

- High pressure grouting construction principle: is a special high-pressure grouting waterproof material through the high-pressure infusion equipment into the concrete crack structure extended until all the cracks (including the naked eye is difficult to meet) filled with water (water) with the cross-linking reaction, Release a large number of carbon dioxide gas, resulting in secondary pressure, high pressure and secondary pressure will be pressed into the elastomer and filled with all the gaps, to stop the purpose of leakage, it can be said that the best performance of plugging material,

- Q: Villa roof leakage what general reasons, what materials to remedy

- First, the roof leak to find the first leak, looking for the main leak from the roof to the lower to find leakage. First look at the roof there is no crack, the original waterproof layer is not aging, the roof of the original waterproof membrane has no bubbles, there are bubbles to prove that the water has entered the bottom of the waterproof layer, and thus leaking, and roof On the gutter there is no clogging.

Send your message to us

Single Component SPU Waterproof Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords