Silica Acid Resistant Silicate Bricks for Chimneys

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Silicate bricks for hot stoves feature sharp dimension,low expansion,little residual quartz, low true density.low creep rate,good thermal shock resistance upon 600°C and high refractoriness under load, It mainly used at high temperature area include arch and upside of hot stove and upside of checker. Andalusite bricks are mainly used in the cooling wall of blast furnace, chemical and ceramic industry, the door of coke oven, or as the lining and checker of hot blast furnaces.

Application:

1 Building materials for blast furnace

2 Building materials for hot-blast stove

3 Building materials for coke oven

4 Building materials for steel making furnace

Advantage:

1.Competitive Price. Make the products competitive in your market.

2.Abundant Experience. Prevent cracks and twist in bricks.

3.Different Moulds. Save mould fees for you.

4.Strict Quality Control. Meet clients' quality requirement.

Typical features:

1 Excellent thermal stability

2 High refractoriness under load

3 Chemical stability and anti-corrision

4 Small high temperature creep rate

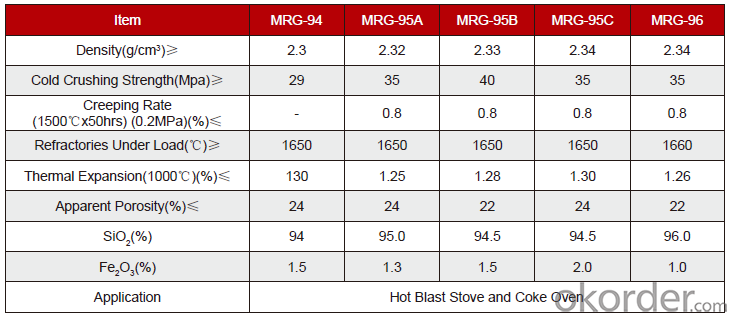

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

- Q: Physical solid waste disposal

- Too much addition will reduce the refractory and mechanical strength, increase porosity, so the amount of waste brick should not be too much.

- Q: The hot blast stove when the temperature did not rise against the brick interface decreased

- Insulation of hot blast stove, key insulation silica brick hot stove, hot blast stove is shutdown or need repairing in blast furnace.

- Q: The specific content is what gb/t2608-2012 brick

- The provisions of the brick classification, technical requirements, test methods,

- Q: The introduction of silica brick

- Brick refers to the content of more than 93% products SiO2. Brick with SiO2 content of not less than 96% of silica as raw materials, adding mineralizer and binder, through mixing, molding, drying, sintering and other processes in the system. The higher the content of SiO2 in silica raw material, the higher the refractoriness of the product. According to the use of brick varieties, divided into: coke oven silica brick, brick for hot blast stove, electric stove with brick, brick for glass furnaces. According to the transformation is divided into: standard bricks, tiles, bricks and general special brick etc..

- Q: Semisilica brick interpretation

- Good thermal shock resistance. In use, more high viscosity glass phase can be formed, and the masonry brick joint and the working surface are dense and the masonry is complete, which is beneficial to improve the impermeability of the masonry and reduce the erosion effect of the slag on the masonry.

- Q: The United States of our brick anti-dumping duties?

- At present of our brick anti-dumping rate is 73.10%

- Q: What are the main constituents of refractory bricks?

- (a) containing refractory brick brick, refers to more than SiO293%, is the main varieties of acid resistant brick. It is mainly used for coke oven building, also used in furnaces all kinds of glass, ceramic and carbon calciner, refractory brick arches and other load-bearing parts, is also used in high temperature bearing part of hot blast stove, but should not be used in thermal equipment below 600 DEG C and the temperature fluctuation in the.

- Q: What is the silica refractory products?

- High silicon content in high temperature expansion sintering temperature between 1390-1410 in furnace arch

- Q: The formula in the refractory brick, and firing curve, who knows?

- Iron scale powder 0.45-0.55%, cement 0.9-1.1%, lime milk 6.5-7.5%, pulp 1.95-2.2%, the silica powder, perlite will be added to the wet mill in proportion, and then add iron scale powder, cement, dry roller 1-2 minutes later

- Q: Such purpose and scope please give me detailed points thank you

- Mainly used for coke oven carbonization chamber and the combustion chamber wall, open hearth furnace regenerator and a sediment chamber, soaking furnace, glass furnace, refractory materials and ceramic brick kiln, kiln vault and other load-bearing parts. Also used for high temperature bearing part of hot blast stove and acid open hearth furnace.

Send your message to us

Silica Acid Resistant Silicate Bricks for Chimneys

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords