Shock resistance to low temperature and environmental protection resin

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features and Benefits

1 . lasting color: Synthetic resin tile surface materials are made of imported ultra-high weatherability Engineering resin produced. By having exceptional durability in the natural environment, even if it is long-term exposure to ultraviolet light, moisture, heat, cold harsh conditions, can still maintain the stability of its color.

2 . excellent resistance to load: good carrying capacity. In the lower temperature region, even if the roof perennial snow, it does not produce surface loss and breakage. After testing, in the case of support from the 750mm, the load 150kg, tile does not produce cracks and damage.

3 . sound effect: The experiment proved: when subjected to external noise heavy rain, high winds, synthetic resin tile has good noise absorption effect.

4 . impact resistance, good low temperature resistance: has a strong ability to withstand external. The test 1 kg steel ball dropped from 1.5M high freedom will not crack, impact resistance at low temperatures is also very significant, after 10 freeze-thaw cycles (-20 to +50 degrees Celsius) without hollowing, blistering, peeling, cracks phenomenon.

5 . excellent corrosion resistance: long-term resist acid, alkali, salt and other corrosive chemicals. Experimental results show: soak for 24 hours without a chemical reaction in salt, alkali and various acids below 60%. Ideally suited for acid rain-prone areas and coastal areas, the effect is particularly significant.

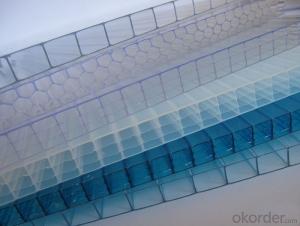

Product Specifications:

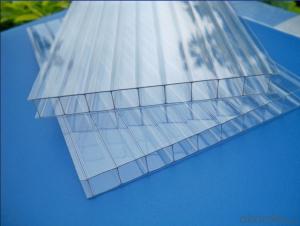

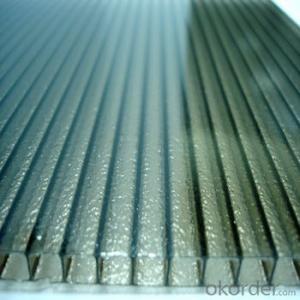

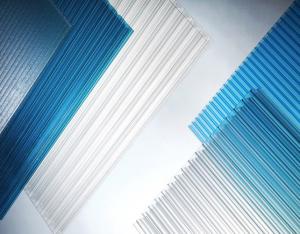

Standard Conventional size: 1220mm (width) * 2440mm (length) * 15mm (thickness), size, thickness, material types are customized according to customer requirements. Material thickness can be selected 5mm, 9mm, 12mm, 15mm, 18mm, 21mm, 25mm and so on

Advantage

1. Persistent color

2. Excellent load resistance

3. Sound: Experimental proof

4. Impact resistance, good low temperature resistance

5. Excellent corrosion resistance

6. Excellent thermal insulation properties

7. Excellent self-cleaning performance

8. Stability

9. Excellent waterproof performance

10. Excellent electrical insulation properties

11. Fire resistance

12. Installation is quick

13. Green

- Q:PC sun panels and color steel plate how to bond

- In fact, with a little bit of weather resistance can be plastic, completely unnecessary Bolts, try HTACK7, you can use self-tapping or bolts, and then neutral sealant;

- Q:To build a sunshine shed, with Cortron PC patience board or good sun board?

- 1, Cortron sun board Advantages: the German Bayer new materials and co-extruded high concentrations of UV, yellowing effect is good light Light, cover the sun room effect is good 2, Cortron Nai Liban Advantages: good light transmission, up to 88% Good temperature resistance, at minus 40 degrees Celsius to 120 degrees Celsius, there will be no deterioration of quality Sound insulation is good Flame retardant, light weight, safe

- Q:Lighting board and sunshine board which is good?

- The panels are made of fiberglass, and the sun panels are made of polycarbonate. Each have their own strengths and weaknesses, see your use. Sun panels used in building lighting, greenhouse shed shed more use. Low-grade will not say, high-end sunshine board can be used for more than a decade is no problem, manufacturers generally guarantee ten years! Sun plate is not strong acid and strong base this is true!

- Q:Company pc sunshine board how to solve the problem

- Two layers of waterproof treatment: sun board endurance board joints with a wide aluminum alloy bar, in the pressure below the bonding of special waterproof tape, and then use a good quality neutral sealant on both sides of the pressure to play the thickness of 5 mm width 5 -8 mm silicone.

- Q:What is the difference between a hollow board and a sunboard?

- But both have a lighting function, which sunshine board lighting performance and weather better and the lighting board is better acid and alkali resistance, not easy to be acid and alkali corrosion, the production process is not the same, the sun is a co-extruded, the production process Slightly more complicated. The lighting plate is connected to the tapping screw and must have a cover plate. Sun plate cold and heat deformation is large, easy to be self-tapping nail cut, so the sun plate in the self-tapping nail should open a larger hole. In the installation of lighting panels to consider the expansion of the lighting board.

- Q:Who can tell me, plastic hollow board and PC sun board in the end what is the difference?

- PC sun panels PC has a deliberately anti-UV performance, mobility is not high, high transparency Ordinary plastic plates can be other materials

- Q:Which friends know how to remove the plastic film on the sun?

- In the PC sun panels and accessories installed when fixed, it is best to tear the protective film 30mm to 50mm, this is to avoid the accessories to suppress the protective film pressure. But should pay attention to is not too much to expose, or easy to install the operation because of scratching the sun plate.

- Q:What is the difference between the PC and the PC board?

- Two products are the same material, but the production process is not the same, the price is generally the same circumstances

- Q:Can sunscreen be insulated at night? PC sunshine board insulation performance how?

- In addition, the thicker the thickness of the polycarbonate PC solar panels, the more layers, the better the insulation performance, but not necessarily the thicker the better, because the PC sheet with the thickness increases, structural complexity, price increases, or to Choose the right one. PC sunshine board during the day cold, night insulation, suitable for greenhouses and other greenhouse lighting insulation use, PC sun panels up to 49% insulation.

- Q:PC sunshine board, what material, what kind of good

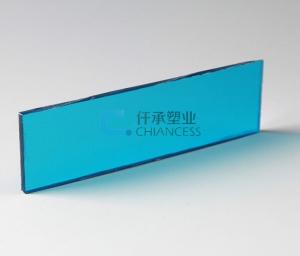

- Hello, the thickness of the sun board is generally 10mm, 8mm, 6mm and other specifications, in the color also has a lake blue, transparent, white and other colors, available to users according to their actual needs and preferences to choose.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Shock resistance to low temperature and environmental protection resin

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords