Shear Studs Connectors Through Decking Ferrule for Building Materials

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Detail

Basic Info

Material: Carbon Steel,Alloy Steel,Stainless Steel

Diameter: 10mm-25mm

Grade: 4.8...etc

Length: 40mm-300mm

Certificate: CE,ISO 9001:2008,Uktc,SGS

Set: Wtih Ceramic Ferrule

Surface Treatment: Plain,Phosphate,Nature

Sample: Free

Delivery Detail: 7-30 Days or According to Your Order

MOQ: 3000PCS

Export Markets: North America, South America, Southeast Asia, Africa, Mid East, Eastern Asia

Additional Info

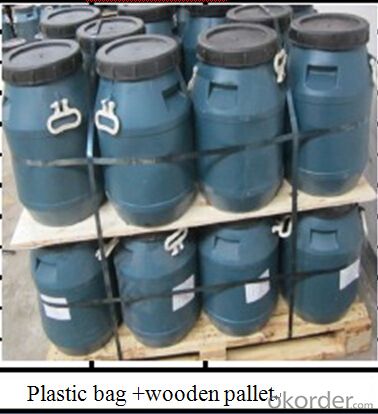

Packing: Carton and Wooden Pallet

Standard: ISO 13918, AWS D1.1, NELSON, BS

Origin: Xiaoshan, Hangzhou, Zhejiang, China

HS Code: 731829

Production Capacity: 1000000PCS/Month

Product Description

Shear Connector Studs are designed to tie the concrete to the steel beams and to resist shear loadings

between the concrete slab and steel beam in composite construction.

Shear connectors on the top flanges of the steel girders provide the means to achieve composite action between the slab and the girders, thus increasing both stiffness and strength.

Fasteners used to attach a structure or object to concrete. They can be used with many base materials including concrete, brick and block. Shear connectors are welded to surfaces in order to resist shear between elements of a composite beam.

Shear studs are used in stud welding to secure steel framed buildings to create a shear connection between

the steel and the concrete. We supply and fix all available sizes of welded shear studs for through deck

and straight to steel welding.

Burn off value shown are for welding to bare steel.

Length: Length is before weld. Stud when welded to base metal will be approximately 5mm shorter after weld and when welded through deck 10mm shorter after weld. Lengths for shear connect studs are generally set by governing specification.

Shear studs are used in stud welding to secure steel framed buildings to create a shear connection between the steel and the concrete. We supply and fix all available sizes of welded shear studs for through deck and straight to steel welding.

All our products meet the current standards and specifications

The ISO 13918 SINOARSTM shear studs (shear connectors) use the ISO13918 standard Type UF and PF ceramic

ferrules,other special type available upon request.

When inquire prices and ordering, please specify name, standard, type, specification (LBW), quantity, special requirements(if have), etc., eg.

Shear Stud, ISO 13918, Type SD, 22x150 (LBW), 60,000 Pieces.

Shear Stud; Shear Connector with Arc Welding; Weld Stud for Steel Decking with

ceramic ferrules.

Shear Connector Studs are designed to tie the concrete to the steel beams and to resist shear loadings

between the concrete slab and steel beam in composite construction.

Shear studs are used in stud welding to secure steel framed buildings to create a shear connection between

the steel and the concrete. We supply and fix all available sizes of welded shear studs for through deck

and straight to steel welding.

Burn off value shown are for welding to bare steel.

The ISO 13918 SINOARSTM shear studs (shear connectors) use the ISO13918 standard Type UF and PF ceramic

ferrules,other special type available upon request.

When inquire prices and ordering, please specify name, standard, type, specification (LBW), quantity, special requirements

(if have), etc., eg.

Shear Stud, ISO 13918, Type SD, 22x150 (LBW), 60,000 Pieces.

Quality Control &Test Assurance Lab

We carry out strict quality control, from high rates inspection of raw material &incoming products to ensure the step quality.

The test for every procesure of producing throughly, we inspect occasionally during the producing process. As we are

dedicated to provide the quality products to our customers. By doing these, we had constantly assured our products 100%

satisfication and get our customer approval for our service and quality.

We are capable to test these in our test assurance lab:

Tensile/proof load testing

Rockwell hardness tester

Micro HV hardness tester

Optical projector

Digital calipers/micrometers for dimensional gauging

Internal and external thread pitch gauging

Different drive penetration

Angle gauging

Electronic digital height gauge

Prouduct Show:

FAQ

Acceptable payment term and way?

T/T,L/C, T/T + L/C,

Acceptable price term?

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: What are some of the common fastener products?

- There is also a fastener called "pin" This fastener is generally used to locate the parts, and sometimes can also be connected to the fixed role, in addition to a part can be used to transmit power or lock other fasteners.

- Q: what parts do Fasteners include

- Screw: also by the head and screw two parts of a class of fasteners, according to the use can be divided into three categories: machine screws, set screws and special purpose screws. The machine screw is mainly used for a fastening screw hole part, with a through hole between the parts of the fastening connection, no nut matching (this connection is called the screw connection, also belong to the detachable connection; Used in conjunction with nuts for fastening connections between two parts with through holes.) The locking screw is mainly used to hold the relative position between the two parts. Special purpose screws such as rings are used for lifting parts.

- Q: Bolts and other connection fasteners some points A B C grade what it means

- Bolts and other fasteners connected due to a wide range of applications, the product level requirements are different, so the bolt product grade is divided into A, B, C three grades. One of the most accurate A, C level of the most inaccurate, B between the two. Class A is used for important applications where assembly accuracy is high and subject to greater impact, vibration or variable loads. Class A for d = 1.6-24mm and l ≤ 10d or l ≤ 150mm bolts. B grade for d> 24mm or l> 10d or l ≥ 150mm bolts, thin rod B grade M3-M20 hexagonal flange bolts, anti-loose performance better. Class C is between M5 and M64.

- Q: Fasteners often say that the nature of galvanized oxidation is what it means

- True color refers to the surface of the fastener is not any treatment, copper is copper color, iron is the color of iron, aluminum is the color of aluminum. Galvanized iron is the surface of the fastener coated with a layer of zinc, the role is rust. Oxidation refers to the surface of the fastener to the chemical reaction, to produce a layer of anti-rust film, the main role is rust, the other can also beautify the appearance.

- Q: In the fastener industry, 1018 refers to what material

- Simple point is the wire friends, the general is the production of screws. Rivet material is generally 1215

- Q: For the commonly used standard parts, for some of the quality of good or bad, how to distinguish,

- If it is important, random to do one or two destructive pull test, their own press with a simple tooling, pay attention to safety, if their own, to the physical and chemical test units or heat treatment of the brothers can do. You can also go to the supplier to monitor the sampling of such a similar test (contract agreed).

- Q: The main meaning is that the design to make some specific requirements to achieve consistency.

- Specification is: can not affect the performance of the product being used, and fully guarantee the effect of fastening.

- Q: Is it hard to heat the fasteners?

- Heat treatment mainly refers to the dipped fire. Dip the fire is not dipped into the water, is the oil. So the quality of oil, dipped in the temperature of the fire, dipped in the fire time are demanding Moreover, some special requirements need to double the fire, the difficulty is indeed great. In addition, heat treatment often take into account the requirements of the next step surface treatment, so have to consider

- Q: What is the name of the screw (fastener)?

- Screw, it was also called "screw" [screw], "screw" (screw). In fact, the screw is known, and the screws, screw rods are different from each other. Screws are generally called wood screws; is the tip of the kind of tip, pitch larger, generally used to tighten wood parts, plastic parts. Screw is a screw (mechanical screw), is the front of the kind of flat head, pitch is small, uniform, generally used to fasten the metal, machine parts.

- Q: Our company to purchase a number of fasteners to see when the CAD drawings in the technical requirements I do not know the specific to write those content

- Name: Bolt nut flat cushion pad - (should be written in the national label) Drawing No .: Ask the engineer Material: Q235 Q235 steel spring steel ---- ordinary 35 steel 35 steel spring steel ---- high strength ratio: according to the actual Drawing quality: check the information or do not fill the level: 4.8 5 200HV 65MN ------ ordinary 8.8 8 300HV 65MN ------ high strength specifications: write their own

Send your message to us

Shear Studs Connectors Through Decking Ferrule for Building Materials

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords