Duck Brand School Stationery BOPP Self-Adhesive Tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 2500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications Of School Stationery Bopp Sel-Adhesive Tape:

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description Of School Stationery Bopp Sel-Adhesive Tape:

The Bopp Tape is of Bopp film as the carrier, coating with water based acrylic adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

General purpose of Bopp Tape: widely used for carton sealing and packaging, light duty packaging, bounding, holding and other office and household use.

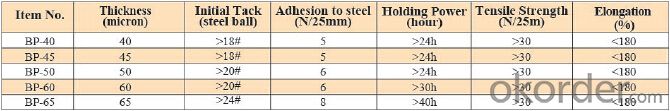

Typical Physical Reports Of School Stationery Bopp Sel-Adhesive Tape:

Packaging Of School Stationery Bopp Sel-Adhesive Tape:

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Width1280mm; length according to customers’ requirements

FAQ Of School Stationery Bopp Sel-Adhesive Tape:

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Double Sided Tissue Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: Can packaging tape be used for sealing foam?

- Yes, packaging tape can be used for sealing foam. Packaging tape is commonly used for sealing boxes and packages, but it can also be used effectively to seal foam. When using packaging tape to seal foam, it is important to ensure that the tape is securely adhered to the foam surface to create a tight seal. This can be achieved by applying pressure to the tape after it has been applied. Additionally, it is recommended to use a tape that is specifically designed for sealing foam, as these tapes often have stronger adhesive properties and are more resistant to temperature changes and moisture. Overall, packaging tape can be a convenient and effective option for sealing foam.

- Q: Are there any safety precautions to consider when using packaging tape?

- Yes, there are several safety precautions to consider when using packaging tape. Firstly, it is important to ensure that you are using the tape in a well-ventilated area, as some adhesive fumes can be harmful if inhaled excessively. Additionally, it is crucial to handle the tape dispenser with care to avoid any injuries. Make sure to use proper hand placement and avoid placing your fingers too close to the cutting blade to prevent accidental cuts. Furthermore, when using packaging tape, it is advisable to wear appropriate protective gear, such as gloves, to protect your hands from any potential adhesive residue or cuts. Lastly, it is essential to store the tape in a safe and secure place, away from children or pets, to prevent any accidental ingestion or misuse. By following these safety precautions, you can ensure a safe and efficient use of packaging tape.

- Q: Are there any special considerations when using packaging tape for fragile items?

- Special considerations must be taken into account when utilizing packaging tape for delicate items. To package fragile items appropriately, it is imperative to select a tape specifically created for this purpose. Seek out packaging tape that is clearly marked as "fragile" or "handle with care," as these tapes are commonly reinforced with added strength and possess unique features aimed at protecting fragile items. When using packaging tape for fragile items, certain specific factors should be considered: 1. Strength and durability: Fragile items necessitate additional protection, making it essential to employ a tape that is both strong and durable. Opt for packaging tape crafted from top-notch materials, such as reinforced fiberglass or heavy-duty polypropylene, to ensure it can endure weight and pressure without tearing or breaking. 2. Cushioning and padding: Fragile items are prone to damage from impacts, thus it is advisable to utilize packaging tape that provides cushioning or padding. Some tapes come with built-in bubble wrap or foam padding, which assists in absorbing shocks and safeguarding delicate items from breakage during transit or handling. 3. Adhesive quality: The adhesive quality of the packaging tape is another crucial consideration. Fragile items may require longer transit times, necessitating the tape to remain securely in place throughout the journey. Look for packaging tape with a robust adhesive that can adhere well to various surfaces, including cardboard boxes, plastics, or glass. 4. Easy removal: Delicate items often require gentle unpacking, thus utilizing packaging tape that is easily removable, without leaving any sticky residue or causing damage, is essential. Some tapes are designed with a low-tack adhesive, making them simpler to peel off without any inconvenience. 5. Clear visibility: It is vital to ensure that fragile items are unmistakably marked to notify handlers and delivery personnel. Utilizing brightly colored packaging tape or tape labeled with a "fragile" message can effectively attract attention and promote careful handling. In conclusion, when employing packaging tape for fragile items, it is crucial to select a tape that possesses strength, durability, cushioning, a high-quality adhesive, and easy removal properties. These considerations will help safeguard delicate items from damage during shipping or handling.

- Q: Are there any eco-friendly options for packaging tape?

- Yes, there are eco-friendly options for packaging tape available in the market today. Traditional packaging tapes are typically made from plastic materials such as polypropylene or PVC, which are not biodegradable and have a negative impact on the environment. However, eco-friendly alternatives have been developed to address this issue. Some options include: 1. Paper-based packaging tape: These tapes are made from renewable resources such as paper and natural adhesives. They are biodegradable, compostable, and recyclable, making them a sustainable choice for packaging needs. 2. Water-activated tape: Also known as gummed paper tape, this type of tape is made from paper and requires water to activate the adhesive. It forms a strong bond when applied to boxes and is tamper-evident. Water-activated tape is biodegradable and can be recycled along with the packaging it is applied to. 3. Biodegradable and compostable tape: These tapes are made from plant-based materials such as cellulose or PLA (polylactic acid). They are designed to break down naturally over time, reducing their impact on the environment. Some options are certified as compostable, meaning they can be added to compost piles or sent to composting facilities. 4. Recycled plastic tape: While traditional plastic tapes are not eco-friendly, there are recycled plastic tape options available in the market. These tapes are made from recycled plastic materials, reducing the demand for virgin plastic and promoting a circular economy. When looking for eco-friendly packaging tape, it is important to consider certifications such as the Forest Stewardship Council (FSC) for paper-based tapes or the Biodegradable Products Institute (BPI) certification for compostable tapes. By choosing these alternatives, individuals and businesses can minimize their environmental footprint and contribute to a more sustainable future.

- Q: Does packaging tape come in different odor-free options?

- Yes, packaging tape does come in different odor-free options. Many manufacturers offer packaging tape that is specifically designed to be odor-free, making it suitable for use in sensitive environments or for individuals who may have allergies or sensitivities to certain scents. These odor-free options are typically made from materials that do not emit any strong smells or fragrances, ensuring a neutral and pleasant packaging experience. When purchasing packaging tape, it is always a good idea to check the product description or labeling to see if it is specifically mentioned as odor-free.

- Q: Does packaging tape come in different lengths?

- Yes, packaging tape does come in different lengths. It is available in various lengths to cater to different packaging needs and requirements.

- Q: Can packaging tape be used for sealing chemical or hazardous material containers?

- Packaging tape is not recommended for sealing chemical or hazardous material containers. This is because packaging tape typically does not have the necessary properties to effectively contain and prevent leakage of these substances. Chemical or hazardous materials often require specialized containers and sealing methods to ensure safety and compliance with regulations. These containers are designed to withstand the corrosive or reactive nature of the substances they hold, and their seals are engineered to provide a secure and leak-proof closure. Using packaging tape to seal chemical or hazardous material containers can pose risks such as leakage, contamination, and exposure to harmful substances. It may not provide a reliable barrier against leaks or spills, which could result in accidents, injuries, or environmental damage. To properly seal chemical or hazardous material containers, it is recommended to use specific sealing materials that are designed for these purposes. This may include specialized caps, gaskets, or seals that are compatible with the particular substance being contained. Additionally, it is crucial to follow the guidelines and regulations provided by relevant authorities for the safe handling, storage, and transportation of these materials.

- Q: The production of transparent tape material is what to do

- BOPP film can be produced by tube or flat film method. The BOPP films obtained by different processing methods have different properties. The BOPP film produced by the flat film method has a higher strength ratio (up to 8-10), so the strength is higher than that of the tube film, and the uniformity of the film thickness is better.

- Q: Can packaging tape be used for sealing protective packaging materials like bubble wrap?

- Yes, packaging tape can be used for sealing protective packaging materials like bubble wrap. It provides a secure and effective way to seal the packaging, ensuring that the contents remain protected during transportation or storage.

- Q: Can packaging tape be used for sealing packages with sharp or pointed objects?

- Indeed, packaging tape is capable of sealing packages that contain sharp or pointed items. Its purpose is to create a reliable seal for packages, effectively keeping together those that hold sharp or pointed objects. Nonetheless, it is crucial to ensure that the tape is tightly fastened and covers all edges and corners of the package to avoid any potential harm or damage during handling or transportation. Moreover, it is advisable to apply multiple layers of tape or employ supplementary protective measures, like cushioning materials, to reinforce the security and safeguard the sharp or pointed items enclosed within the package.

Send your message to us

Duck Brand School Stationery BOPP Self-Adhesive Tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 2500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords