Perforated Aluminum Strips - Roof Sheets Price Per Sheet Aluminum Coil 1050 Alibaba Stock Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

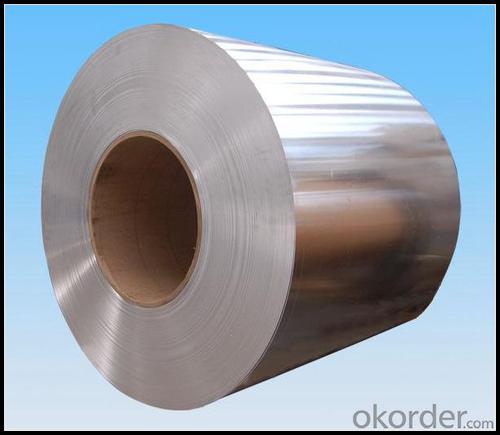

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding oil and petrochemical industries...

(2).Exterior: wall cladding...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

Aluminium is 100 percent recyclable with no downgrading of its qualities. The re-melting of aluminium requires little energy: only about 5 percent of the energy required to produce the primary metal initially is needed in the recycling process.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Explain the distinctions between aluminum sheets and aluminum strips.

- <p>Aluminum sheets and aluminum strips are both flat aluminum products, but they differ in width and thickness. Aluminum sheets are wider and can range from 0.2mm to 500mm in thickness, suitable for applications requiring broad surfaces like construction and packaging. Aluminum strips, on the other hand, are narrower and typically used in applications that require thin, elongated pieces, such as in electrical conduits or mechanical parts. The production processes may also vary, with sheets often being rolled and strips being extruded or rolled as well, depending on the specific application and desired properties.</p>

- Q: Is there any risk associated with the use of aluminum strips for roofing and siding purposes?

- <p>While aluminum strips are generally safe for roofing and siding, there are a few concerns to consider. Aluminum can expand and contract with temperature changes, which may lead to buckling or warping over time. Additionally, it is a good conductor of heat and electricity, so it may not provide the best insulation or protection against lightning strikes. Aluminum is also prone to denting and can be noisy in heavy rain or hail. However, it is lightweight, durable, and resistant to corrosion, making it a popular choice for many homeowners. Proper installation and maintenance are crucial to minimize these risks.</p>

- Q: Is it possible for a non-professional to install an aluminum strip roof?

- <p>Yes, it is possible to install an aluminum strip roof without a professional, but it requires some basic knowledge of roofing and carpentry skills. You'll need to measure and cut the aluminum strips to fit your roof, secure them with nails or screws, and ensure proper overlap for water resistance. It's important to follow the manufacturer's instructions and safety precautions. However, if you're not comfortable with DIY projects or if your roof is complex, hiring a professional is recommended to ensure the job is done correctly and safely.</p>

- Q: Classification of aluminium strips of aluminium strips

- There are specific uses: aluminum aluminum (aluminum foil transformer) transformer, high frequency welding hollow aluminum strip, aluminum strip used for aluminum fin radiator belt, cable aluminum strip, aluminum strip, aluminum strip punching with aluminum belt etc..

- Q: This question asks for the most suitable type of aluminum strip for outdoor applications.

- <p>The best type of aluminum strip for exterior use is typically 3003-H14 alloy. This alloy is known for its excellent corrosion resistance, which is crucial for outdoor applications where the strip may be exposed to various weather conditions. It also offers good formability, making it easy to shape and bend for various construction and architectural purposes. Additionally, 3003-H14 aluminum strip has good weldability, which is beneficial for applications where joining is required. It is commonly used for roofing, siding, and other exterior applications due to its durability and weather-resistant properties.</p>

- Q: This question asks for methods to clean and maintain aluminum strips to ensure their longevity and functionality.

- <p>To clean and maintain aluminum strips, start by using a soft cloth or sponge with warm soapy water to gently remove dirt and grime. Avoid abrasive materials that could scratch the surface. After cleaning, rinse thoroughly with clean water and dry immediately to prevent water spots. For stubborn stains, a mild detergent or a specialized aluminum cleaner can be used. Regularly inspect the strips for signs of corrosion or damage and address these promptly. Apply a protective coating if needed, especially in outdoor applications, to prevent oxidation. Keep aluminum strips away from harsh chemicals and extreme temperatures to maintain their integrity.</p>

- Q: What other materials could potentially be used in place of aluminum strips for specific uses?

- <p>Yes, there are alternative materials that can replace aluminum strips in certain applications. These include stainless steel, which offers high strength and corrosion resistance; copper, known for its excellent electrical conductivity; magnesium alloys, which are lightweight and have good thermal conductivity; and titanium, prized for its strength and resistance to corrosion. The choice of material depends on the specific requirements of the application, such as strength, weight, cost, and environmental factors.</p>

- Q: Is it possible to create a more energy-efficient roof using aluminum strips compared to other materials?

- <p>Yes, aluminum strips can be used to create a roof that is more energy-efficient than some other materials. Aluminum is a good conductor of heat, which can help in reflecting sunlight and reducing heat absorption, thus lowering cooling costs. Additionally, aluminum roofs can be designed with energy-efficient features such as solar reflectance and thermal emittance properties, which can further enhance their energy efficiency. However, it's important to consider the overall design, insulation, and installation quality to maximize energy efficiency.</p>

- Q: Explain how aluminum strips enhance the performance and durability of bicycles.

- <p>Aluminum strips contribute to bicycle performance and durability by providing a lightweight and strong material for the frame and components. Aluminum's low density reduces the overall weight of the bike, enhancing its acceleration and climbing capabilities. Its high strength-to-weight ratio allows for thinner frame walls without compromising structural integrity, which improves rigidity and power transfer from the rider to the wheels. Additionally, aluminum's resistance to corrosion and fatigue means that the bike can withstand harsh weather conditions and repeated use without significant wear and tear, thus increasing its longevity and reliability.</p>

- Q: This question asks for the various factors that can influence the pricing of aluminum strips.

- <p>The price of aluminum strips is influenced by several factors, including the global supply and demand dynamics, the price of aluminum on the commodities market, production costs, transportation expenses, tariffs and trade policies, market competition, and economic conditions. Additionally, the quality and specifications of the aluminum strips, such as purity and thickness, can also affect pricing. Fluctuations in energy costs, especially for electricity used in the smelting process, can impact production costs and, consequently, the price of aluminum strips. Lastly, geopolitical events and environmental regulations can also have an indirect effect on the availability and cost of aluminum, thus influencing strip prices.</p>

Send your message to us

Perforated Aluminum Strips - Roof Sheets Price Per Sheet Aluminum Coil 1050 Alibaba Stock Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords