Residental Concrete Hollow Core Floor Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Residental Concrete Hollow Core Floor Machine

1. Residental Concrete Hollow Core Floor Machine:

The machine uses hydraulic lifting system, easy to revolve. It can reduce labor intensity and improve production efficiency. Machine body adopts anti-rust technology. Key parts, like hopper are welded by stainless steel. Wearing parts like reamers, side form, vibration board, stock guide and other parts are all welded with alloy. Both sides of the wall panels can put reinforcement wires, diameter can reach 6mm. Work area is orbital or no orbital.

According to the specialty of the local materials, we provide matching method to insure customer produce standard panels (general materials: fly ash, slag, ceramsite, cinders, cinerite, pumice, vermiculite and so on). Reduce the overall cost of building, increase indoor usable space.

High production efficiency, annual output square meters above 150000m.

2. Main Features of Residental Concrete Hollow Core Floor Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Simple structure, easy operate, less wear parts

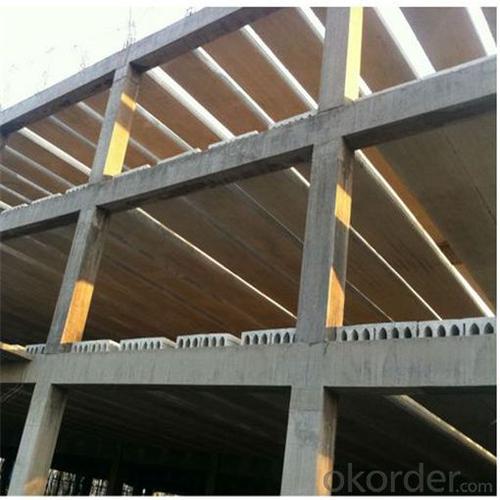

3. Residental Concrete Hollow Core Floor Machine Images:

4. Residental Concrete Hollow Core Floor Machine Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Process

Rebar tensioning

Raw materials preparing

Molding

Our customers

5. Packing & Delivery

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: I plan to dig a deep hole in Central Texas and the dirt is rather hard. I will be working alone. What hand tool would allow be to do this quickiest?

- a pick and shovel. if it is that hard soaking it with water will likely turn it back to clay, you will have a hard time working in it. my idea would still be hire a tractor with a post hole digger on it and make several holes at the same spot all the way around the area then shovel it out. depends on the size though you said big and in texas it must be really big then right? if so try a bull dozer then reseal where the dozer went into the pit, when done, you may die of exhaustion before finishing,otherwise

- Q: I bought an Oasis Machinery Dust Collector. Any free replacement bags?

- es okorder

- Q: What kind of materials can EDM machine

- Theoretically, any conductive material can be machined with a wire EDM machine.

- Q: but the problem is that some materials are not available in india and i want to search the any material with same compositions of the requird materials. so is there any website or any book from where i can find that

- Matweb okorder

- Q: please explain at 1 or 2...or 3. no current experiment please like knockout mice.

- 1) the Avery,Mcleod and Mccarty experiment. 2)the Hershey and Chase experiment. _ Hershey and Chase conducted their experiments on the T2 phage, a virus whose structure had recently been shown by electron microscopy.In their first set of experiments, Hershey and Chase labeled the DNA of phages with radioactive Phosphorus-32 (the element phosphorus is present in DNA but not present in any of the 20 amino acids from which proteins are made). They allowed the phages to infect E. coli.were able to observe the transfer of P32 labeled phage DNA into the cytoplasm of the bacterium.n their second set of experiments, they labeled the phages with radioactive Sulfur-35 (Sulfur is present in the amino acids cysteine and methionine, but not in DNA). Following infection of E. coli they then sheared the viral protein shells off of infected cells using a high-speed blender and separated the cells and viral coats by using a centrifuge. After separation, the radioactive S35 tracer was observed in the protein shells, but not in the infected bacteria, supporting the hypothesis that the genetic material which infects the bacteria was DNA and not protein hope it helps.:)

- Q: Is there any difference between the two words? I want to name a company's name, the product is machines.By the way, what about packing and packaging? are the different. The machine is mainly packaging facilities, how can i name the company's name?

- ya 1 machine vs more than 1 machine

- Q: green company purchased a piece of machinery on credit for 10,000.Briefly state how this transaction affect th?

- Green okorder

- Q: Framework for oil well drilling machinery?

- Derrick

- Q: what do companies benefit from when upgrading machinery?

- Depends what you mean by upgrading. A business can upgrade existing machinery to perform faster, better, etc or they can purchase a new machine to replace an older one. With upgrading the business is looking at increasing output, reducing operating costs and improving the efficiency of the machine. A new machine will potentially return less downtime due to breakdowns, but may have teething troubles whilst it settles in. New machinery will have costs involved, not only the purchase cost, but cost of spares, cost of training to operate and maintain, and depreciation. Hope this helps

- Q: Reconditions will do, will need some for places with dire needs

- The okorder /

Send your message to us

Residental Concrete Hollow Core Floor Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords