Repairing Mannual Tongs with API 7K Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Repairing Mannual Tongs Description

The Repairing Tongs are designed and manufactured in accordance with the API Spec 7K-2005《Specification for Drilling and Well Servicing Equipment》and the National Standard for the Petroleum Gas Industry SY/T 5035-2004 《Elevator links ,elevators and tongs》.

This tool is used to fasten or remove the screws of drill tool and casing in well drilling operation. Changing the latch lug jaws and handling shoulders can adjust the handing size of the tongs.

2. Main Features of the Repairing Mannual Tongs

1) API standard;

2) Very Good Quality;

3) After-sale Service.

3. Repairing Mannual Tongs Images

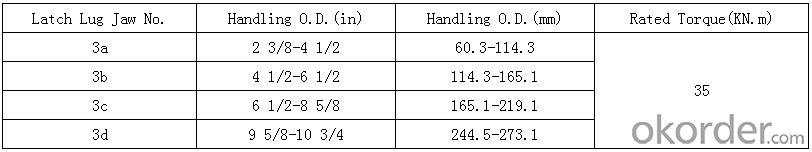

4. Repairing Mannual Tongs Specification

5. FAQ of Repairing Mannual Tongs

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class supplier of Mannual Tongs. Our products have been sold to various domestic oilfields and exported to Europe, America, Middle East, Central Asia, North Africa and South-East Asia and other overseas regions.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

We will arrange the delivery as soon as possible after receiving the contract.

- Q: What spare parts does mine machinery equipment have?

- Self developed products: 2.2 tons of double bottom unloading ore and rail adsorption stopper for the national patent products.

- Q: What are the common faults of tower cranes? Removal method

- 1., the tail thread and withdrawal groove, hook surface cracks2. hook dangerous section wear3., hook and bending parts of permanent deformation

- Q: China's most powerful mine wear parts

- In addition, the wear-resistant parts of the processing technology and technology is very important, it is best to find professional wear-resistant parts processing enterprises to do, such as steel and so on.

- Q: What are the accessories for mining machinery?

- Wear parts: screen plate, hammer head, guard board (also known as lining board), jaw crusher jaw plate,

- Q: What are the accessories for mining machinery?! Mainly refers to?

- Screws, screws, caps, lubricants, gears, belts are things used in mining machinery. Do you understand?

- Q: How to do the maintenance of mining machinery parts?

- Mining machinery belong to large-scale equipment, the purchase of new equipment and frequent replacement parts will consume a lot of money, and affect the enterprise production schedule, therefore, how to correct for mine equipment maintenance so as to prolong the service life of the equipment is very important. The following is the Aupu mining machinery for you to collate how to maintain mechanical parts

- Q: I would like to ask the general mine machinery industry, the purchase of accessories must not go to the original factory to buy?

- Not necessarily, it is best to buy the original factory, after all, they are supporting the production of it!

Send your message to us

Repairing Mannual Tongs with API 7K Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords