PVC Foam Sheet with Best Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

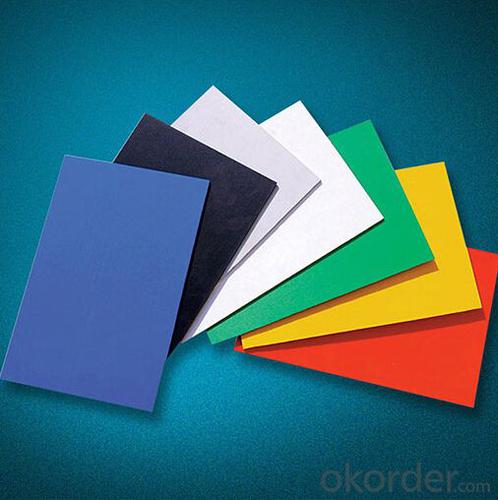

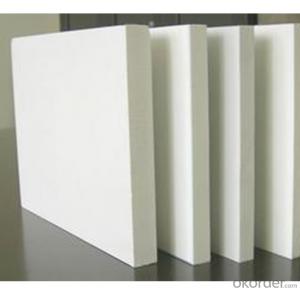

PVC Foam Sheet, a kind of high-tech product, is one product of Kingstar Plastic Sheet series. Through special machinery and technology processing, the main material PVC resin can be foamed and extruded into a special sheet with many advantages, such as shinny or matt surface, waterproof, flame-resistant, UV stable, sound and heat insulation, anti-chemical corrosion, etc.

Kingstar PVC Foam sheet is manufactured by the equipment imported from well-known Italian Bausano Group and Austria Cincinnati Company. We, with more than 15 years' processing experience, have invented several formulas to ensure every piece of sheet could be perfectly used.

Application

Advertising Signs, billboards, displays, exhibition stands

Screen printing, laser engraving

Thermoformed parts

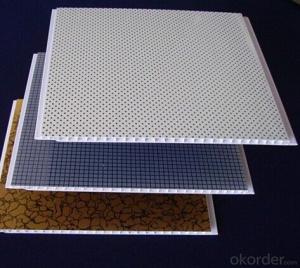

Architecture, indoor and outdoor decoration

Furniture, kitchen & bathroom cabinet

Walls & partitions, wall cladding

Poolside furniture, swimming pool floor planking

Board for Chemical industry and laboratory equipment

Interior scaleboard for boat & ship, vehicle, train

Features

Light weight, easy and convenient to storage, transportation and use

It could be drilled, sawed, nailed, turned, glued, bended, printed, oiled, etc

Uniform fine & close cell structure

Hygienic, Rigidity, Durable

Perfect chemical corrosion resistance, good resistance to UV & weathering

Fire retardant and self extinguishing

Moisture-resistant, mildew proof, rot proof, low water absorption

Non-deformation, color fastness for a very long time

Sound insulation, sound absorption, heat insulation and heat preservation

Easily to put protective film on one or two sides

Smooth surface and suitable for silk-screen printing, laser engraving (must clean the surface before printing)

- Q: Members XDJM: I work for reasons, a set of home hair blank room idle, recently wanted to simply rent out the rent. A friend said that the floor can be used home PVC floor shop, but we do not understand these things, please help my friends to answer my question, thank you: 1, the thickness of the general requirements of home PVC floor is how much? Requirements can not be easily trampled, hit rotten. 2, PVC floor of the construction conditions is what? Molding room floor can be used directly? 3, my home or the developer of the floor when the developer, the cement is not particularly flat (there are more holes, as if there is no cement road level), with what 4, some people say to brush plastic, need not? Hope that these or their own use of the reply, I only 30 points, all the reward

- You said the ground is not cement road level, there are a lot of holes, I do not know you are not the ground is the sand from the like, if there is a sand from the proposed you do not do cement self-leveling so that the quality of your floor There is no guarantee that the ground is not cement road Ping suggested that you do not do cement self-leveling and do not say how the effect of the cost is too high, the cement self-leveling to find someone to do the price of 15-25 yuan per square meter, and cement self-leveling Each can only do 2-4MM meters, that is to say that you want to make a good effect at least have to do 2 to 3 times, so the cost is too high, I do many years of PVC flooring, it is recommended that you shop The ground before the first to find a good way to find the mud on the ground so that you will be less to a lot of cost and the effect of the bottom out of the floor will be much better

- Q: Pvc board and fire board glue what glue?

- Due to the waterproof performance of the fire board is very good even the big white scraping in the above are not easy to fall but the effect is more fishing solid smooth, with ordinary brother two good or other glue can be very good paste together.

- Q: Pvc how to heat the deformation of soft board, to make their own shape

- Small on the hair dryer, the factory on the infrared or oven heating

- Q: Such as the thickness is 5MM size is 417 * 512 size is calculated area? We 5mm thickness of the board is 0.25 yuan / cm to help me count Kazakhstan price a lot of hey? How is the calculation formula calculated?

- PVC transparent board Product thickness: 2-20mm Maximum width of products: 1300mm Product Length: 100-10000mm Recommended Specifications: 1300 × 2000mm PVC soft board (coil) Product thickness: 1-10mm The maximum width of the product 1300mm Product Length: Unlimited Recommended Specifications: Width 1300 mm, weight 50kg / roll PVC hard board Product thickness limit: 25mm or less. The following are the same as the " Product width: 900mm, 1300mm, 1500mm.

- Q: Density board and PVC which expensive

- The same specifications PVC expensive

- Q: What kind of plastic plate does the water tank make

- Do water tanks are generally made of PVC plastic sheet. PVC, English referred to as PVC (Polyvinyl chloride), vinyl chloride monomer (vinyl chloride monomer, referred to as VCM) in the peroxide, azo compounds and other initiator; or in the light and heat under the free radical polymerization mechanism Polymerized polymer. Vinyl chloride homopolymer and vinyl chloride copolymer collectively referred to as vinyl chloride resin. PVC is an amorphous structure of the white powder, the degree of branching is relatively small, the relative density of 1.4 or so, the glass transition temperature of 77 ~ 90 ℃, 170 ℃ or so began to decompose, the stability of light and heat poor, above 100 ℃ or for a long time Sun exposure, it will break down and produce hydrogen chloride, and further automatic catalytic decomposition, causing discoloration, physical and mechanical properties are rapidly declining, in practical applications must be added stabilizer to improve the stability of heat and light.

- Q: What is the difference between PVC board and oak board?

- 1.PVC plate is PVC as raw material made of cross-section of the honeycomb mesh structure of the plate. Is a vacuum plastic film, used for all kinds of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foam board. ? 2. The oak board is a kind of wood that is made of furniture or decorative material. Mainly used for making furniture.

- Q: PVC plastic hard board maximum temperature how much

- More than 70 degrees will be deformed, more than 130 degrees will begin to melt ~!

- Q: Pvc board do cabinet how exactly? Urgent demand

- Well, beautiful decorative effect is good, durable and solid ah, but also cheap, alternative wood products

- Q: Pvc floor how much money

- Surface treatment is not the same, the price is not the same, this does not determine the answer

Send your message to us

PVC Foam Sheet with Best Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords