PVC Foam Board Extruder for Plastic Sheets - Wholesale Offers

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

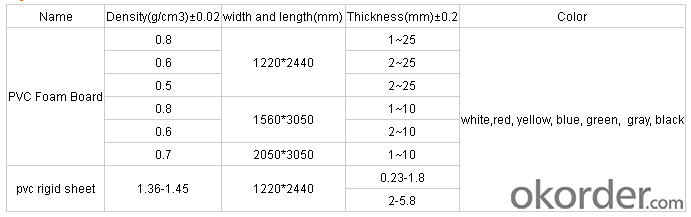

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

quantity(influence the delivery time and prices)

3. Product Features

1.Waterproof, fireproof retardant, moistureproof, anticorrosive, Weather resistant, moth-proofing, anti cracking, anti UV.

2.Less warping, stand wear and tear, acid and alkali resistance, easy coloring, no glue and paint

3.Can be nailed, drilled, shaved, chiseled, riveted, With wood properties and better than wood, color diversity

4. Safety and environmental protection, formaldehyde-free

5. Easy to install, easy to clean, easy to maintain

4. Product Application

Application fields | The specific application |

Household furniture | tables , chairs , benches , stools – furniture, Sofa, Box spring, Bookshelf, clothing case, tea table, screen, frame, handle, plate, bar, newspaper rack. |

Construction | Mobile home, window frame, door plank, threshold, template, concrete stairs clap, wallboard, ceiling, floor, and various profiles, etc |

Industrials | Chemical corrosion barrack and public places, decorating plate, floor, channel, bench, and the casting model, the machine cover, pump shell, electrical materials, etc |

........ | |

5.More Details of Product

- Q: What is an extrusion plate?

- With high thermal resistance and low linear expansion ratio, the characteristics of the low, the obturator structure rate reached more than 99%, the formation of a vacuum layer, avoid air flow cooling, to ensure that the insulation performance of lasting and stable, relative to the closed cell foam polyurethane rate of 80%, the leading advantage is self-evident. Practice has proved that the insulation effect of 20mm thick XPS extruded insulation board is equivalent to that of 50mm thick foamed polystyrene and 120mm thick cement perlite. Therefore, this material is currently the best choice for building insulation.

- Q: What are the different thickness options for plastic sheets?

- The thickness options for plastic sheets can vary greatly depending on the type of plastic and its intended use. Common thicknesses range from 0.5mm to 25mm, with some specialty plastics available in even thicker options.

- Q: Can plastic sheets be used for vacuum forming?

- Yes, plastic sheets are commonly used for vacuum forming. The process involves heating the plastic sheet until it becomes pliable, then applying vacuum pressure to shape it over a mold. This method is used to create various products and packaging materials.

- Q: Would you please help me find clear, acetate sheets that are heat resistant and thick enough to be a card rather than just overlay a card?

- What Are Acetate Sheets

- Q: Are plastic sheets resistant to bending in extreme temperatures?

- Yes, plastic sheets are generally resistant to bending in extreme temperatures. However, the degree of resistance may vary depending on the specific type and composition of the plastic material.

- Q: How do plastic sheets handle pressure?

- Plastic sheets have varying degrees of strength and flexibility, so their ability to handle pressure depends on their composition and thickness. Thicker and more rigid plastic sheets tend to handle pressure better, while thinner and more flexible ones may deform or break under significant pressure.

- Q: We're building a crude mock yacht for a party of some sorts and we want to imitate the shininess by wrapping shiny white bendable plastic sheets around the outside of the wood frame. Does anyone know what I should use and where I can get it?

- Mcgrath is a very dedicated and experienced woodworker who knows what he is talking about when it comes to woodworking and DIY projects s he has been a woodworker for many many years. Read here https://tr.im/OGmpl There is also a lifetime member acess included in the package and you get these extras for no cost to you as they are free with no additional charges at all!

- Q: I have started sewing checkbook covers recently. They seem to need something to stabilize them, and I have been using cardboard. I was wondering if anywhere sells thin plastic sheets (like margarine/yogurt lid thickness) that I could cut to fit. I don't sew through it, it would be removable. Or somewhere online would work too.... or any suggestions to use stuff I already have! Thanks for your help! :)

- Plastic canvas works well for that. Michaels and Hobby Lobby both have it.

- Q: Can plastic sheets be used for manufacturing equipment?

- Yes, plastic sheets can be used for manufacturing equipment. They are commonly used in various industries for applications such as machine guards, conveyor belts, housing components, and protective covers. Plastic sheets offer several advantages including durability, versatility, corrosion resistance, and cost-effectiveness, making them a popular choice for manufacturing equipment.

- Q: Hi guys! I once saw a plastic sheet with milky color. When coveredagainst a dark background plate, one can write on it with an ink-lesspen. But when the pastic is taken off the background plate, the handwritingdisappears. Do you know what it is and where I can buy it?

- the front sheet is an opaque pvc over a dark blue card with blue wax over it. when you write on the pvc it presses the pvc onto the wax and the text appears, pulling the pvc away from the wax removes the image and resets the tablet.

Send your message to us

PVC Foam Board Extruder for Plastic Sheets - Wholesale Offers

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords