High Strength PVC Coated Polyester/Fiberglass Geogrid Geocells for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

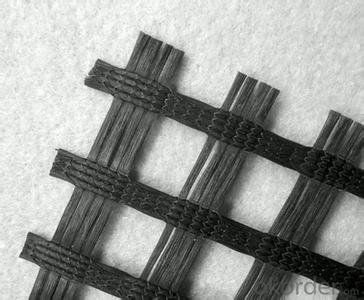

Introduction of Fiberglass Geogrid:

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance, as well as convenience in construction and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Applications of Fiberglass Geogrid:

--- Reinforcement for road pavement

--- Reinforcement for railway basement

--- Reinforcement for Tunnel

--- Reinforcement for Slope

--- Reinforcement for embankment.

Features:

1.Intensity of vertically and horizontally from 20 KN/M to 150 KN/M

2.Low breaking elongation, not bigger than 3%

3.Suitable for each kind of soil environment

4.For treatment on surface, the rib suppresses the rough pattern, strengthens the grill surface the rough degree, enhances the GSZ steel plastic complex geogrid in the soil body friction factor.

5.It has more superior breadth, up to 2- 6 m, reducing construction joining, enhances the work efficiency.

6.High intensity, low creep and distorting

7.Resistant to erosion, longer life.

8.Easy and convenient to install, short period and low cost- saving. It can save project cost by 10%- 50%.

FAQ:

Q: Can you accept small trial order?

A: Yes, we accept small trial orders at reasonable charge.

Q:May I get one sample for checking out the quality? How much?

A: Yes, we supply sample free of charge, and the freight will be on buyer’s account, which is refundable when order confirmed.

Q: What is your MOQ?

A: Normally, 1000 m2 per order.

Q: What is your delivery time? Can we have it sooner?

A: 2 days for sample, 3-5 days against 1x40HQ

Q: What is your payment terms?

A: T/T, Paypal (3% surcharge), Western Union or 30% deposit 70% L/C.

- Q: Geogrid construction must be folded back 2m wrapped in compacted packing on it?

- Edit this section of geogrid construction notesPaved geogrid should be smooth, paving layer after acceptance, to prevent longitudinal askew phenomenon, according to the width of paving layer or draw white thread, you can start paving, and then use the end of the nail fixed grid (nail 8, per meter wide uniform fixed distance) well, after the end of the fixed grid, with the paving machine will grill slowly pulled forward each shop, shop 10 meters long artificial tightening and straightening once, until a volume grating puwan, put the next volume, operation with a roll of puwan with roller 6T-10T from the starting point to begin the direction of rolling over, (steel rolling as road paving in the surface layer and the leveling layer, the machine is appropriate; such as grid laid directly on the concrete pavement, with the roller roller is appropriate) ground shop: Volume long unit as the laying of the long, the grid should be covered the long shop Full, then the overall check a paving quality, and then paving the next section, the next section of paving, grille and grille can be used lap length 10-15CM, and fixed with nails or wedge to shop in second, to the direction followed by analogy with operating requirements.

- Q: What are the two levels of widening of the geogrid in the asphalt concrete road?

- If it is not clear, you can ask me

- Q: Are geogrids resistant to puncture?

- Yes, geogrids are generally resistant to puncture due to their high tensile strength and durability. They are designed to withstand puncture forces from sharp objects or heavy loads, making them suitable for various applications in civil engineering and construction projects.

- Q: What is the typical geogrid roll length for specific applications?

- The typical geogrid roll length for specific applications can vary depending on the specific project requirements and the manufacturer's offerings. However, it is common to find geogrid rolls with lengths ranging from 50 to 500 feet.

- Q: Can geogrids be used in ground improvement projects?

- Yes, geogrids can be used in ground improvement projects. Geogrids are commonly used to reinforce and stabilize soil, improving its bearing capacity and preventing soil erosion. They are effective in a variety of ground improvement applications such as road construction, retaining walls, and slope stabilization.

- Q: How do geogrids enhance the stability of railway track embankments?

- Geogrids enhance the stability of railway track embankments by providing additional reinforcement and preventing soil erosion. They improve load distribution, increase bearing capacity, and reduce settlement, ultimately ensuring the long-term stability of the embankment.

- Q: I would like to ask what kind of railway construction materials?Under the trouble of experts who can help me explain these materials. I am engaged in the procurement of Railways in this regard, I want to rush to prepare the information

- Building conventional materials do not say, the following is only part ofWaterproof agentPrestressed steel strand

- Q: Do geogrids provide reinforcement to geosynthetic asphalt liners in landfill covers?

- Yes, geogrids provide reinforcement to geosynthetic asphalt liners in landfill covers.

- Q: What are the design considerations for geogrids in mechanically stabilized earth walls?

- The design considerations for geogrids in mechanically stabilized earth walls include factors such as the required strength and stiffness of the geogrid material, the appropriate selection of geogrid type (uniaxial or biaxial), the spacing and orientation of the geogrid layers, and the connection and anchoring methods between the geogrid and the wall facing. Other considerations may include the soil characteristics, slope stability, and potential loads or forces acting on the wall. Overall, the design aims to maximize the geogrid's reinforcement effect and ensure the stability and durability of the mechanically stabilized earth wall.

- Q: Are geogrids resistant to chemical degradation?

- Yes, geogrids are typically resistant to chemical degradation. They are designed to withstand exposure to various chemicals commonly found in soil and water, making them durable and suitable for long-term applications in civil engineering and construction projects.

Send your message to us

High Strength PVC Coated Polyester/Fiberglass Geogrid Geocells for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords