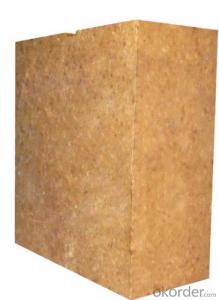

High Alumina Brick - Professional Manufacturer for High Alumina Bubble Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Physical and chemical index:

Item | AKZ-85 | AKZ-90 | AKZ-99 | |

Chemical composition | Al2O3 | ≥85 | ≥90 | ≥99 |

SiO2 | ≤13 | ≤8 | ≤0.2 | |

Fe2O3 | ≤0.5 | ≤0.5 | ≤0.5 | |

Apparent Porosity% | 58-62 | 58-62 | 58-62 | |

Bulk Density g/cm3 | 1.4-1.7 | 1.4-1.7 | 1.4-1.7 | |

Cold Crushing Strength Mpa | ≥12 | ≥10 | ≥9 | |

0.1Mpa Refractoriness Under Load T0.6 °C | ≥1650 | ≥1700 | ≥1700 | |

Permanent Linear Change On Reheating (%)1500°CX2h | ±0.3 | ±0.3 | ±0.3 | |

20-1300°C Thermal Expansion % (x 10-6) | 0-7.8 | 0-8.0 | 0-8.6 | |

Thermal Conductivity(Average 800°C) W/(M.K) | ≤0.8 | ≤1.3 | ≤1.5 | |

Max Service Temperature °C | 1680 | 1700 | 1800 | |

Packaging & Shipping

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Block | Material: | Alumina Block |

| SiO2 Content (%): | 8 | Al2O3 Content (%): | 90 | MgO Content (%): | 0 |

| CaO Content (%): | 0 | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | 0 |

| SiC Content (%): | 0 | Model Number: | AKZ-85 90 99 | Brand Name: | cnbm |

| Name: | high alumina bubble refractory bricks | size: | any size | Item: | AKZ-90 |

| Al2O3: | 90 | SiO2: | 8 | Fe2O3: | 0.5 |

| Apparent Porosity%: | 58-62 | Bulk Density g/cm3: | 1.4-1.7 | Cold Crushing Strength Mpa: | 10 |

| 0.1Mpa Refractoriness Under Load T0.6 °C: | 1700 |

Packaging & Delivery

| Packaging Details: | Wooden pallet or as the customer's requirments |

| Delivery Detail: | 30 Days |

- Q: What are the high aluminum bricks made of?

- The amount of refractory mud accounts for about 6% of the brick weight

- Q: What are the reasons for the spalling of refractory bricks in the production of lime kiln?

- Therefore, the choice and masonry of refractory bricks are of vital importance. If there is a brick kiln kiln off block process of reproduction, is now because of the use of refractory brick kiln material mostly three grade high alumina bricks. The content of AL2O3 is about 55%, of which the content of Fe2O3 is about 2%, which is weak, and the alkali corrosion resistance is a little worse. In a containing three grade high alumina bricks in the composition of AL2O3, Si2O3, and other elements also contain K, Na trace, were the most, thus causing the system of the low melting point is very low, even at 1400 DEG C has been liquid phase, and generate CaAL12O19 limestone and calcium feldspar etc.. Form corrosion loss. Therefore, a long time will cause the loss of block. On the one hand, it may be caused by construction.

- Q: What are the alloy wear resistance materials?

- According to the composition of Beijing Naimo metal materials company will wear resistant metal materials is divided into the following five categories: one: high manganese steel series: high manganese steel (ZGMn13),

- Q: How much is one ton / ton of high alumina refractory brick?

- The market price of about super high aluminium brick price at 3000 yuan / ton, a high aluminum brick at around 2500 yuan / ton, two high aluminum bricks at around 2100 yuan / ton three grade high alumina bricks at around 1850 yuan / ton for reference, choose to buy the area is not the same as the prices are not the same.

- Q: Corundum, high alumina and fireclay refractory difference is what

- In fact, they are not consistent with raw materials, corundum refractories can use white corundum, white corundum, brown corundum corundum material, alumina content of these materials is higher than 90%, while the high aluminum refractory material is bauxite, alumina in 90 to less than 70, and clay raw materials the aluminum content is less than 70..

- Q: The difference between ordinary and diatomite brick refractory brick

- To say the difference, the material is the biggest difference. There are diatomite brick density, compressive strength of small brick kiln belongs to the outer thermal insulation, and heavy refractory brick kilns for multi village in direct contact with the flame, high temperature resistance, good compressive strength, but no insulation. Hope to help you.

- Q: What does refractory consist of?

- Refractory materials can be divided into main raw materials and auxiliary raw materials according to their function in the production process of refractory materials.The main raw material is the main body of refractory. Auxiliary raw materials can be divided into binders and additives. The role of bonding agent is to make the refractory body in the production and use process has enough strength. There are commonly used lignin, phenolic resin, asphalt, cement, water glass, phosphoric acid and phosphate, sulfate, some main raw material itself has the effect of binder, such as clay; additive is to improve the production of refractory materials and construction technology, or strengthen the refractory material of some properties, such as stabilizer, water reducing agent, inhibitor, plasticizer, foaming agent, dispersing agent, bulking agent, antioxidant.

- Q: What's the weight of the refractory bricks?

- Fireclay refractory bricks: 3.4kg-3.8kg - according to the quality of raw materials, prices ranging from 1 yuan to 2.7 yuan, high alumina refractory brick: three, high aluminum in 3.9kg or so. Ordinary T-3 firebrick weight calculation method: 230*114*65*2.2/2.1.

- Q: What is the apparent porosity of high alumina brick?

- In the production of high alumina bricks in addition to the entity, there are many different sizes and shapes of different pores, pores can be divided into three categories: one side closed the other side and the outside world is called open pores, closed in the product not communicated with the outside is called closed pores, penetrating through pores called the few products.

- Q: The difference between clay bricks and clay bricks

- According to the hole rate: solid brick (no hole or hole rate less than 25% bricks), porous brick (hole rate is equal to or greater than 25%), the size of the hole is small and the number of bricks, usually used in load-bearing parts, higher strength level. Hollow brick (hole rate equal to or greater than 40%, large pore size and small amount of brick, commonly used in non load parts, low strength grade).Solid bricks and porous bricks are mostly used for load-bearing structural walls. Hollow bricks are mostly used in non load bearing structures.

Send your message to us

High Alumina Brick - Professional Manufacturer for High Alumina Bubble Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords