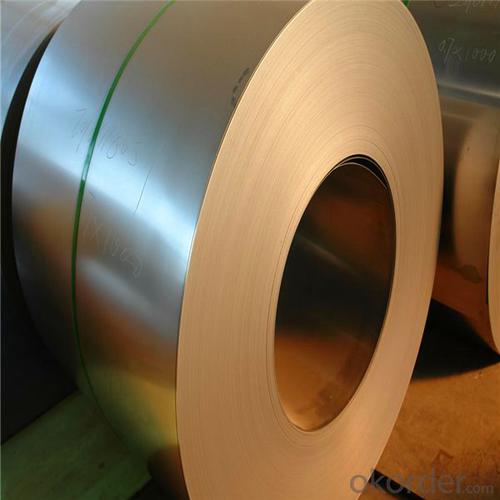

Prime Quality Cold Rolled Steel Sheet/Coil Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Prime Quality SPCC Cold Rolled Steel Sheet/coil

| Usage | Widely used to appliance,automobile industry or other decoration usage. |

| Certificate | ISO9001 |

| Packing Details | Wrapped by water proof paper and plastic film.Covered with iron sheet,strapped by steel strips to protect the damage under transportation. |

| Payment term | 30%T/T in advance, the balance would be paid against the product list of manufacturer before loading,or L/C at sight |

| Delivery | 25-30 days |

| Tolerance | As the standard required |

Brief Introduction

Cold rolled steel coil is steel that has been worked below its recrystallization temperature by passing it between a pair of rollers. Recrystallization temperature is the temperature at which grains in the lattice structure of the metal have been rearranged, leaving it free of strain and deformations. Cold rolled steel coil is pre-treated before being cold rolled with a process known as pickling, which uses strong acids to remove scale and other impurities. The cold rolled steel coil is then passed through rollers to reduce its thickness. Most cold rolling takes place in multiple passes and as the size of the cold rolled steel coil is further reduced, its strength and hardness both increase, but its ductility decreases. After cold rolling, heating the metal up in a process known as annealing can restore some of its ductility. The final cold rolled steel coil may be manufactured in the form of sheets, strips, bars, or other forms.

- Q: How are steel products used in the chemical industry?

- Steel products are widely used in the chemical industry for various applications such as storage tanks, pipes, and equipment due to their high strength, durability, and resistance to corrosion. These steel products help store and transport chemicals safely and efficiently, ensuring the integrity of the substances being handled. Additionally, steel is often used in the construction of chemical plants and refineries, providing a stable and secure infrastructure for chemical processes.

- Q: What are the different types of steel fasteners?

- There are several types of steel fasteners, including screws, bolts, nuts, washers, and rivets. These fasteners are commonly used in construction, automotive, and manufacturing industries for joining or securing various materials together.

- Q: What are the different types of steel fasteners and their uses in the aerospace industry?

- There are several types of steel fasteners used in the aerospace industry, including bolts, screws, nuts, and rivets. Bolts are commonly used to join two or more components together and provide strong and durable connections. Screws are used for securing smaller parts and are available in various sizes and thread types. Nuts are used in conjunction with bolts to create secure connections, and they come in different shapes and sizes. Rivets, on the other hand, are permanent fasteners used to hold two or more pieces of material together by creating a mechanical joint. These fasteners play a critical role in maintaining the structural integrity and safety of aircraft components in the aerospace industry.

- Q: What are the common types of steel products used in the pet photography and videography industry?

- In the pet photography and videography industry, some common types of steel products used include tripods, camera mounts, light stands, and backdrop support systems. These steel products provide stability and durability, ensuring steady shots and capturing the perfect moments with pets.

- Q: How are steel pipes used in oil and gas pipelines?

- Steel pipes are commonly used in oil and gas pipelines due to their strength, durability, and resistance to harsh environments. These pipes are used to transport oil and gas from extraction sites to refineries and end-users. They are laid underground or underwater and can handle high pressure and temperature variations. The steel pipes also provide protection against corrosion and external damage, ensuring a safe and efficient flow of oil and gas throughout the pipeline network.

- Q: How is steel sheet metal stamped for automotive parts?

- Steel sheet metal is typically stamped for automotive parts using a process called metal stamping. This involves feeding a flat sheet of steel into a stamping press, where a die is used to shape and cut the metal into the desired automotive part. The press applies immense pressure to the steel sheet, causing it to deform according to the shape of the die, resulting in accurately stamped automotive components.

- Q: How are steel products used in the energy sector?

- Steel products are used extensively in the energy sector for various applications such as power generation, transmission, and storage. For example, steel is used in the construction of power plants, including the building of boilers, turbines, and support structures. It is also utilized in the manufacturing of transmission towers, pipelines, and storage tanks for oil, gas, and renewable energy sources. Steel's strength, durability, and corrosion resistance make it a crucial material in ensuring the efficient and reliable functioning of energy infrastructure.

- Q: How is steel plate produced?

- Steel plate is produced through a process called steelmaking, which involves melting iron ore in a blast furnace and adding various alloys to achieve the desired properties. The molten steel is then poured into a casting machine to form a slab, which is further processed through rolling mills to reduce its thickness and improve its surface finish. This process results in the production of steel plate, which can be used in various industries for construction, manufacturing, and infrastructure projects.

- Q: What are the uses of steel in the construction of shopping malls and retail centers?

- Steel is commonly used in the construction of shopping malls and retail centers due to its strength, durability, and cost-effectiveness. It provides structural support for the building, allowing for large open spaces and flexible layouts. Steel also enables the construction of multi-level structures, including parking garages and mezzanine floors. Additionally, steel's fire resistance properties enhance the safety of these commercial buildings.

- Q: What are the different types of steel coatings?

- There are several types of steel coatings available, including galvanized, aluminized, zinc-nickel, epoxy, polyurethane, and polyvinylidene fluoride (PVDF) coatings. Each type offers unique properties and benefits, such as enhanced corrosion resistance, improved durability, and increased aesthetic appeal. The choice of coating depends on the specific application and desired outcome.

Send your message to us

Prime Quality Cold Rolled Steel Sheet/Coil Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords