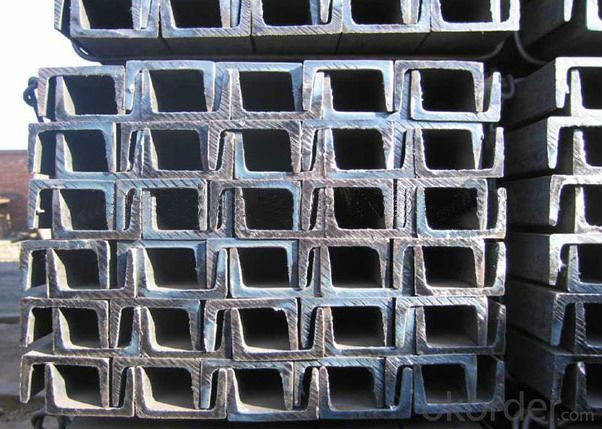

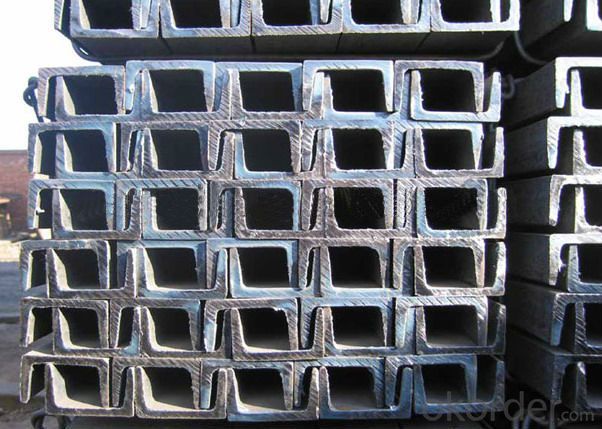

Prime Hot Dipped Cable Bridge C Channel Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prime Hot Dipped Cable Bridge C Channel Steel Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS,ASTM /GB/ BS | Dimensions: | 1.0MM--8.0MM | Grade: | Q195-235,SPCC,SPCH,Q195-Q235 |

| Place of Origin: | Hebei China (Mainland) | Brand Name: | CNBM | Model Number: | GTLM-CS-026 |

| Shape: | C Channel | Application: | Steel Structure, Building,1).Steel Structure. 2).Engeneering | Perforated Or Not: | Is Perforated |

| Length: | any length as per ur request. Common not more than 12m | Thickness: | 4.1.0--8.0mm | Surface: | 1). Puch hole or not 2). Painting or not 3). Galvanized,bright |

| Name: | C channel steel/ C section steel | Raw material: | hot rolled strip, cold rolled strip, galvanized steel strip |

Packaging & Delivery

| Packaging Detail: | bundles by steel strip,in container or as ur request |

| Delivery Detail: | 20days after received deposit or affirm contract |

Prime Hot Dipped Cable Bridge C Channel Steel Specifications

Size | Weight (kg/m ) | Size | Weight (kg/m ) |

80×40×20×2.5 | 3.925 | 180×60×20×3 | 8.007 |

80×40×20×3 | 4.71 | 180×70×20×2.5 | 7.065 |

100×50×20×2.5 | 4.71 | 180×70×20×3 | 8.478 |

100×50×20×3 | 5.652 | 200×50×20×2.5 | 6.673 |

120×50×20×2.5 | 5.103 | 200×50×20×3 | 8.007 |

120×50×20×3 | 6.123 | 200×60×20×2.5 | 7.065 |

120×60×20×2.5 | 5.495 | 200×60×20×3 | 8.478 |

120×60×20×3 | 6.594 | 200×70×20×2.5 | 7.458 |

120×70×20×2.5 | 5.888 | 200×70×20×3 | 8.949 |

120×70×20×3 | 7.065 | 220×60×20×2.5 | 7.4567 |

140×50×20×2.5 | 5.495 | 220×60×20×3 | 8.949 |

140×50×20×3 | 6.594 | 220×70×20×2.5 | 7.85 |

160×50×20×2.5 | 5.888 | 220×70×20×3 | 9.42 |

160×50×20×3 | 7.065 | 250×75×20×2.5 | 8.634 |

160×60×20×2.5 | 6.28 | 250×75×20×3 | 10.362 |

160×60×20×3 | 7.536 | 280×80×20×2.5 | 9.42 |

160×70×20×2.5 | 6.673 | 280×80×20×3 | 11.304 |

160×70×20×3 | 8.007 | 300×80×20×2.5 | 9.813 |

180×50×20×2.5 | 6.28 | 300×80×20×3 | 11.775 |

180×50×20×3 | 7.536 | ||

180×60×20×2.5 | 6.673 |

Prime Hot Dipped Cable Bridge C Channel Steel Pictures

- Q: What are the weight calculations for steel channels?

- To determine the weight of steel channels, one can utilize the following formula: Weight can be found by multiplying the cross-sectional area with the density of steel. The cross-sectional area of a steel channel can be determined by multiplying the width (W), height (H), and thickness (T) of the web. In the case of tapered flanges, the average width (Wa) of the flanges should be employed. To calculate the cross-sectional area, add twice the average width of the flanges to the width, multiply the sum by the height, and add the product of the thickness and width. The density of steel typically measures approximately 7,850 kilograms per cubic meter (kg/m³). Hence, the weight of the steel channel can be established by multiplying the cross-sectional area by the density of steel. To ensure accurate weight calculations, it is crucial to employ consistent units for all measurements, such as meters or millimeters. Additionally, it is advisable to verify the specific dimensions and specifications of the steel channel being utilized, as they may vary.

- Q: How do steel channels contribute to the structural integrity of a building?

- The construction industry relies heavily on steel channels, which play a crucial role in maintaining the structural integrity of buildings. These channels, also known as C-channels or U-channels depending on their shape, provide essential support, stability, and strength to the overall structure. One of the primary functions of steel channels is their ability to bear heavy loads. They are commonly used in constructing beams, columns, and other structural elements that bear the weight of the building. Due to the high strength-to-weight ratio of steel, these channels effectively distribute and transfer loads, ensuring the stability of the building and preventing structural failures. Moreover, steel channels are highly versatile and can be easily fabricated into different shapes and sizes, making them suitable for a wide range of construction applications. They can be joined together through welding or bolting to create rigid frames, forming a robust framework for the building. This flexibility allows architects and engineers to design structures capable of withstanding various types of loads, including vertical, horizontal, and lateral forces. Additionally, steel channels offer excellent resistance to corrosion, which is particularly important in areas with high humidity or harsh weather conditions. Their durable nature ensures the longevity of the building, reducing the need for frequent maintenance and repairs. Another noteworthy advantage of steel channels is their fire resistance. Unlike other building materials, steel has a high melting point, making it less prone to structural failure during a fire. This characteristic enhances the safety of the building and contributes to its overall structural integrity. Furthermore, steel channels can contribute to the energy efficiency of the building. They can be designed to accommodate insulation materials, improving thermal performance and reducing energy consumption. By minimizing heat transfer and maintaining comfortable indoor temperatures, steel channels help create a more sustainable and cost-effective building. In conclusion, steel channels are essential components in ensuring the structural integrity of buildings. Their load-bearing capabilities, versatility, resistance to corrosion and fire, as well as their contribution to energy efficiency, make them a preferred choice for architects and engineers. By incorporating steel channels into the construction process, buildings can be constructed to withstand various forces and endure for a long time.

- Q: Can steel channels be used in coastal areas?

- Yes, steel channels can be used in coastal areas. However, it is important to consider the corrosive effects of saltwater on the steel. Proper coatings and maintenance are necessary to protect the steel from corrosion caused by the saltwater environment.

- Q: Are steel channels suitable for use in the construction of storage racks?

- Yes, steel channels are suitable for use in the construction of storage racks. Steel channels are commonly used in the construction industry due to their strength and durability. They provide excellent support and stability for storage racks, allowing them to hold heavy loads without bending or warping. Additionally, steel channels can be easily customized to fit specific storage needs, making them a versatile choice for constructing storage racks. The corrosion resistance of steel also ensures that the racks will last for a long time, even in harsh environments. Overall, steel channels are a reliable and suitable option for use in the construction of storage racks.

- Q: What are the different methods of installation for steel channels?

- There are several methods of installation for steel channels, including welding, bolting, and adhesive bonding. Welding involves joining the channels using a high-temperature process that creates a strong and permanent connection. Bolting involves using bolts and nuts to secure the channels together, allowing for easier disassembly if needed. Adhesive bonding utilizes strong adhesives to bond the channels, providing a reliable and versatile installation method. The choice of installation method depends on factors such as the application, load requirements, and ease of installation.

- Q: What are the different shapes available for steel channels?

- Steel channels, also known as C-channels or U-channels, come in a variety of shapes to suit different applications and requirements. The most common shapes available for steel channels include: 1. Standard Channels: These are the most widely used and commonly available steel channels. They have a C-shaped cross-section, with equal flanges that are parallel to each other. Standard channels are often used for structural applications, such as supporting beams or framing. 2. Back-to-Back Channels: Also known as double channels or double C-channels, these steel channels consist of two standard channels placed back-to-back and welded or bolted together. Back-to-back channels provide increased strength and rigidity, making them suitable for heavy-duty applications like racking systems or conveyor frames. 3. Tapered Channels: Tapered steel channels have unequal flanges, with one flange wider or thicker than the other. These channels are designed to distribute weight and load more efficiently, making them useful in applications where weight reduction or specific load-bearing capabilities are required. 4. Hat Channels: Hat channels, also known as C-purlins or Z-purlins, have a unique shape resembling the letter "H" or "Z". They are commonly used in construction for roof and wall framing, as well as in the automotive industry for reinforcing vehicle structures. Hat channels provide excellent strength and stiffness while minimizing weight. 5. Custom Shapes: In addition to the standard shapes mentioned above, steel channels can also be custom designed and fabricated to meet specific requirements. Custom shapes may include curved channels, perforated channels, or channels with special cut-outs or patterns, depending on the intended application. It is important to note that the availability of different shapes may vary depending on the manufacturer and the specific steel channel product line. Therefore, it is advisable to consult with a steel supplier or manufacturer to determine the range of shapes available for steel channels.

- Q: Can steel channels be used in corrosive environments?

- Steel channels can be utilized in settings where corrosion is present, but it is crucial to carefully consider the specific kind of steel employed and the required level of corrosion resistance. Typically, steel channels are constructed from carbon steel, which can be vulnerable to corrosion when exposed to moisture, chemicals, or other corrosive elements. Nevertheless, there are multiple alternatives accessible for corrosion-resistant steel channels. A commonly chosen option is stainless steel channels, which are alloyed with chromium and other elements to offer exceptional resistance to corrosion. Stainless steel channels are particularly suitable for implementation in extremely corrosive environments, such as marine applications, chemical processing plants, and wastewater treatment facilities. Another possibility is galvanized steel channels, which are coated with a layer of zinc to safeguard against corrosion. The zinc coating acts as a sacrificial barrier, corroding initially to prevent the underlying steel from being exposed to corrosive elements. Galvanized steel channels are frequently utilized in outdoor or industrial environments where corrosion resistance is imperative. It is essential to evaluate the severity of the corrosive environment and seek advice from experts or engineers to identify the most appropriate steel channel material for a specific application. Additionally, regular maintenance, proper cleaning, and the application of protective coatings can aid in prolonging the lifespan of steel channels in corrosive environments.

- Q: What are the different types of support methods for steel channels?

- Depending on the application and structural needs, various support methods are available for steel channels. Some commonly used methods include: 1. Beam and column supports: Beams and columns can provide vertical support and distribute the weight of the steel channel. This method is frequently employed in building construction, where steel channels serve as structural components. 2. Hanging supports: Steel channels can be suspended using rods, cables, or chains. This method is suitable when the channel needs to be elevated or hung from a ceiling or overhead structure. 3. Bracket supports: Brackets fixed to a wall or other surface can offer lateral support and stability to steel channels, preventing bending or twisting under load. This method is popular in shelving systems or wall-mounted installations. 4. Channel supports: Steel channels can be supported by other channels, forming an interconnected support system. This approach is useful when multiple channels need to be joined to create a larger structure or framework. 5. Channel cleats: Channel cleats, metal brackets bolted or welded to the channel and then fixed to a supporting structure, can provide a secure and rigid connection. This method ensures a sturdy support for the channel. 6. Channel frames: Multiple channels can be connected to form a frame or structure, providing support for steel channels. This method is often used in applications like conveyor systems or equipment supports. In conclusion, the selection of a support method for steel channels should take into account factors such as the specific application, load requirements, and desired level of stability and rigidity. Professional engineers and designers should carefully consider these factors to choose the most suitable support method for their project.

- Q: What are the different quality control measures for steel channels?

- There are several quality control measures for steel channels that ensure their strength, durability, and overall quality. Some of these measures include conducting visual inspections to check for any defects or imperfections, performing dimensional checks to ensure accurate measurements, conducting mechanical tests to assess the strength and load-bearing capacity, and implementing surface treatment processes to prevent corrosion and enhance the appearance. Additionally, steel channels may undergo non-destructive testing methods such as ultrasonic or magnetic particle inspections to detect any internal flaws. Overall, these quality control measures help guarantee that steel channels meet the desired specifications and industry standards.

- Q: What does channel 150*8 mean?

- The back grade of channel steel is 150MM, and the thickness of channel steel is 8MM

Send your message to us

Prime Hot Dipped Cable Bridge C Channel Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords