Price Sanitary Stainless Steel Butterfly Valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

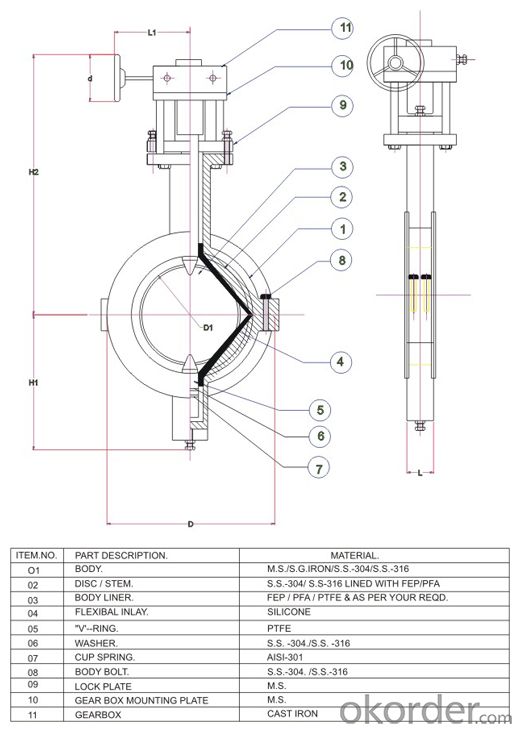

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

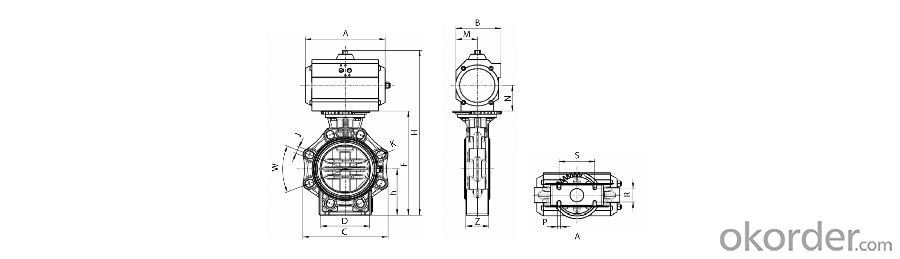

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: What valve should be used to test the water valve?

- 1, ball valve.2, the water test valve can be ball valve, gate valve, stop valve, installed in the fire sprinkler system at each level of the end of the pipe.

- Q: I would like to ask how the valve entry, for a new pair, really difficult, what cutaway view, there are other, just contact the valve less than a week, and sometimes it is really difficult to understand. Forget the experienced teacher can be generous with your criticism to later, indebted forever, learn the valve Comrades some help.In a company CAD to relatives as soon as possible to a company, and then slowly improve, I do not know what is the request of the novice, and how to start as soon as possible, I am learning routine is: give me a set of valve design drawings, and then I paint it on, do not understand the structure and workshop look. I wonder if you have any good learning methods that can be referred to and supplemented by younger brother

- May learn some basic knowledge of valves, learning in practice, relatively fast.

- Q: What is a lift rod valve?

- Lever valve stem nut in the valve plate, it with the disc (hand wheel) to open the turn, its stem pull the valve head and higher than the valve disk, also known as the bar valve. It is different from the dark rod valve, dark rod valve stem nut in the valve body, when the disc rotates, the stem will not rise.

- Q: Which industries need valves?

- 3., the other side of energy development is energy conservation, so from the perspective of energy conservation, it is necessary to develop steam traps, and to sub critical and supercritical high parameter development;4., the construction of power stations to large-scale development, so the use of large diameter and high pressure safety valve and relief valve, but also need to quickly open and close the valve;5., for the needs of complete sets of projects, the supply of valves from a single species to more varieties and specifications. The valve required for an engineering project is growing with the full availability of a valve manufacturer.In the next few years, the overall trend in demand for the valve for the upward trend, the valve of this large volume of industrial supplies, its demand in steady growth. Among them, the demand for a larger number of valves in turn are: ball valve (15.5%), cut-off valve (12.9%), safety valve (12.5%), gate valve (12.5%), butterfly valve (10.6%), regulating valve (8%) and check valve (6.1%).

- Q: What does the valve "4" mean?

- An inch of eight points, home tap, valve is generally 4 points

- Q: I'm going to put a solar energy and an electric water heater installed in the same hot water pipe, a valve, a valve open and close the valve B and vice versa the installation of solar and electric water heater, there can be no linkage valve?

- Yes, three ball valves (T and L) are two. Switch more complex point of the valve is basically ball valve, such as central air-conditioning commonly used to the four - way reversing valve.

- Q: What does the ZH41 valve ZH41 mean, and what other specifications?

- Is the model wrong? The correct one should be Z41HGate valve, hand flange connection name, rod type single gate, sealing surface is alloy steel

- Q: What items and detailed procedures should be inspected for valve size inspection?

- Internet access can be downloaded, such as free standards to share and download sites. If you need any other valve standard, send me the mailbox.

- Q: How does the valve open?

- This is a three pass, not a valve. It doesn't open often or often closes and there is no opening or closing. Can change the same caliber of the valve, you can use the handle switch.

- Q: How does the valve rust die?

- The treatment of valve rust is as follows:1, use corner grinder cut off valve, and then a small mill grinding wheel cutting residual film cut pipe installed in the screw part, when the attention of cutting depth.2, with the amount of hydrochloric acid corrosion and rust of the valve, until the rust completely removed, rinse with water.3, on the newly purchased valve galvanized, can effectively prevent rust.Valve (Famen) is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure. Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow.

Send your message to us

Price Sanitary Stainless Steel Butterfly Valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords