polycarboxylic acid,slump reteation type

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Classification: | Chemical Auxiliary Agent | Place of Origin: | China (Mainland) | Type: | concrete admixture |

| Usage: | Coating Auxiliary Agents,Water Treatment Chemicals | | Model Number: | PCE | |

| | | Solid Content (%): | 50±1.05 | Na2SO4 Content: | 4.0max |

| Na2O+0.658K2O: | 2.0max | Chloride Content: | 0.200max | density: | 1.020~1.050 |

Packaging & Delivery

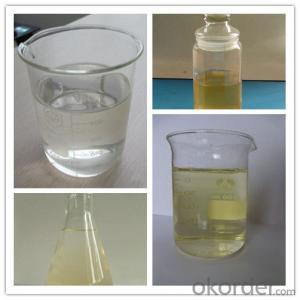

| Packaging Detail: | this product is liquid, should be stored in a plastic container with a cover, avoid the rain water leakage and sundries mixed with or moisture to evaporate run dry |

| Delivery Detail: | Within 7 days after your determinations |

Polycarboxylate superplasticizer with 50% solid content

Polycarboxylate superplasticizer with 50% solid content is suitable for the prefabricate of construction and cast in place concrete, reinforced concrete and prestressed concrete such as high-speed railway, passenger dedicated line, industrial and civil building, road, bridge, port, airport.And it especially suitable for the products like requiring the construction time is long with the prepared concrete and the demanding the concrete slump retaining is higher, such as the nuclear power engineering.

The performance of the product form as follows:

Technical Parameters of Hongsha polycarboxylate superplasticizer | |||

Test items | Performance indicators | Test results | |

Formaldehyde content,% | ≤0.05 | 0.003 | |

Cement paste fluidity,% | ≥240 | 273 | |

Sodium content,% | ≤5.0 | 1.1 | |

Chloride ion content,% | ≤0.2 | 0.13 | |

Alkali content(Na2O+0.658 K2O),% | ≥5.0 | 1.8 | |

Gas content,% | Concrete used for the preparation of non-frost | ≥3.0 | 4.5 |

Concrete used for the preparation of antifreeze | ≥4.5 | ||

Slump retention, mm | 30min | ≥180 | 195 |

60min | ≥150 | 175 | |

Water reduction ratio,% | ≥20 | 25 | |

Atmospheric bleeding rate ratio,% | ≤20 | 0 | |

Pressure bleeding rate ratio,% | ≤90 | 45 | |

Compressive strength ratio,% | 3d | ≥130 | 172 |

7d | ≥125 | 166 | |

28d | ≥120 | 153 | |

Steel corrosion effect | No rust | No rust | |

Shrinkage ratio,% | ≤135 | 97 | |

Relative durability index,% 200 | ≥80 | 85 | |

Advantages

Low dosage 0.2~0.6% of cementitious material.

Water reduction up to 25~40%.

Wide adaptability, can used in all kinds of concrete projects and cement products.

Meet the international standards environmental protection rules :ISO14000 .

Packing and Storage

①Plastic drum:200KG/drum or 1000KG/drum

②Flexitanks

③Clients' packing is available

④It remains effective in one year. After the expiration date, it can be used again if testing results fall within the established range.

The competitive advantage of product line:

The supplier can export products to all over the world, provides ODM, OEM services, passes ISO 9001:2008, CCC certification.

Production Capacity:

| Product Line Name | Production Line Capacity | Actual Units Produced(Previous Year) |

|---|---|---|

| Masonry Materials, Chemical Auxiliary Agent | Ketone Group Water Reducer 1,650 Tons / Month, HSA Amino-superplasticizer Water Reducing Admixture 450 Tons / Month, Polycarboxylate Superplasticizer 90 Tons / Month | Ketone Group Water Reducer 7,091 Tons, HSA Amino-superplasticizer Water Reducing Admixture 1,317 Tons, Polycarboxylate Superplasticizer 674 Tons |

Export Market Distribution:

| Market | Revenue(Previous Year) | Total Revenue (%) |

|---|---|---|

| Southern Europe | USD 500,000 | 5.0 |

| South Asia | USD 1,000,000 | 10.0 |

| Domestic Market | USD 8,500,000 | 85.0 |

Production Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Enamel Reaction Kettle | 5,000 L | 3 | 10.0 | Acceptable |

| Mixing Tank | 5,000 L | 2 | 6.0 | Acceptable |

| Finished Product Storage Tanks | 50,000 L, 100,000 L | 8 | 6.5 | Acceptable |

Testing Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| PH Tester | PHS-25 | 1 | 2.0 | Acceptable |

| Electrical Balance | FA1004 | 1 | 2.0 | Acceptable |

| Drying Box | 202-00 | 1 | 2.0 | Acceptable |

| Pressure Bleeding Rate Meter | SY-2 | 1 | 2.0 | Acceptable |

| Penetration Resistance Meter | ZC-1A | 1 | 2.0 | Acceptable |

| Ultraviolet-uisible Spectrophotometer | UV752 | 1 | 2.0 | Acceptable |

| Flamephotometer | FP6400 | 1 | 2.0 | Acceptable |

| Containing Gas Analyzer | CA-3 | 1 | 2.0 | Acceptable |

| Electric Hydraulic Press Machine | TYA-2000 | 1 | 2.0 | Acceptable |

| Analytical Balance | TG328A(S) | 1 | 2.0 | Acceptable |

Production Flow:

Raw Material Feeding

Chemical Reaction

Finished Production Mixing

Solidification

Testing

Packaging

Real Case for Lower MOQ:

| Products Name | MOQ(in the last 12month) |

|---|---|

| Ketone Group Water Reducer | 1*20GP |

| HSA Amino-superplasticizer Water Reducing Admixture | 1*20GP |

| Polycarboxylate Superplasticizer | 1*20GP |

Send your message to us

polycarboxylic acid,slump reteation type

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords