Plastic Waste Pipe and Fittings PPR Pipe Fitting for Hot or Cold Water Brass Ball Valve High Class Quality Standard from China New

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Products

Place of Origin: Henan, China (Mainland)

Model Number: PE100

Material: PE

Specification: DN 20-mm~DN1200mm

Length: According to customer requirement

Thickness: SDR11/13.6/17

Standard: ISO

Color: many colors

Product name: Plastic Pipe

Application: house and garden

Usage: Family Decoration Industry

Certification: ISO Certificate

Feature: Lightweight

Size: Customized Size

Type: Round Pipe

Name: HDPE Plastic Pipe

Connection: Butt Fusion

Size

Normal Sizes for CNBM PPR Pipe | |||||

Outside Diameter(mm) | Wall Thickness(mm) | Package(m/bale) | |||

S5 PN1.25MPa | S4 PN1.6MPa | S3.2 PN2.0MPa | S2.5 PN2.5MPa | ||

20 | 2 | 2.3 | 2.8 | 3.4 | 120 |

25 | 2.3 | 2.8 | 3.5 | 4.2 | 120 |

32 | 2.9 | 3.6 | 4.4 | 5.4 | 80 |

40 | 3.7 | 4.5 | 5.5 | 6.7 | 60 |

50 | 4.6 | 5.6 | 6.9 | 8.3 | 40 |

63 | 5.8 | 7.1 | 8.6 | 10.5 | 24 |

75 | 6.8 | 8.4 | 10.1 | 12.5 | 16 |

Specification

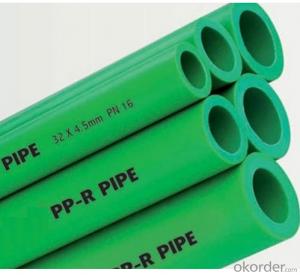

1.Material: | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | L/C, T/T, D/P,D/A |

Products Show

Product Advantages

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving.

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden

installation

9) Recyclable, environment-friendly, accords with GBM standards

Packaging Details

1. Large carton: 515 x 400x 220 Cubage: 0.04532 M3

Small carton: 390x255x250 Cubage: 0.0248 M3

2. PE poly bag+ carton Delivery Detail: 15 days/ 20" containers; 25 days/ 40HQ

FAQ

Q:How to get free samples?

A: Send your address, your telephone number, post code, and express account number to our

mail box .and told us which model of samples you need.

Q:Who pay for the express cost?

A: We can support you free samples each model 1-3 pcs, and we do not pay for express cost.

Q:What is your packing?

A: usually plastic bags, carton, can be packed as your require.

- Q: PPR pipe fittings, copper pieces, that are embedded parts and plastic parts are not good, appear pressure leakage situation

- The water supply pipe is connected with the metal pipe polypropylene, polypropylene pipe should be used with metal fittings as a transition, the pipe and the plastic pipe by hot melt connection, connected with the metal fittings or sanitary hardware fittings with wire.

- Q: Can plastic pipe fittings be used for hot water applications?

- Yes, plastic pipe fittings can be used for hot water applications. However, it is important to choose fittings that are specifically designed and rated for use with hot water to ensure they can withstand the temperature and pressure requirements of the system.

- Q: What are the common installation methods for plastic pipe fittings?

- The common installation methods for plastic pipe fittings include solvent welding, compression fittings, push-fit fittings, and heat fusion.

- Q: Are plastic pipe fittings suitable for use in pharmaceutical manufacturing?

- Plastic pipe fittings are generally not suitable for use in pharmaceutical manufacturing due to the risk of contamination. Stainless steel or other hygienic materials are preferred to maintain the integrity and sterility of pharmaceutical products.

- Q: Can plastic pipe fittings be used in stormwater management systems?

- Yes, plastic pipe fittings can be used in stormwater management systems. Plastic fittings are commonly used in stormwater management systems due to their durability, resistance to corrosion, and ease of installation. They are also cost-effective and have a long lifespan, making them suitable for various stormwater management applications.

- Q: Can plastic pipe fittings be used in fire detection systems?

- No, plastic pipe fittings cannot be used in fire detection systems as they do not meet the necessary fire safety standards and are not designed to withstand high temperatures. Metal fittings are required to ensure the integrity and reliability of the system in case of a fire.

- Q: Can plastic pipe fittings be used for stormwater management systems?

- Yes, plastic pipe fittings can be used for stormwater management systems. Plastic pipe fittings are commonly used in these systems due to their durability, corrosion resistance, and ease of installation. They are also cost-effective and can withstand the harsh weather conditions and varying water flow rates associated with stormwater management.

- Q: How do you select the right plastic pipe fittings for a specific application?

- To select the right plastic pipe fittings for a specific application, several factors must be considered. First, determine the type of plastic pipe being used, such as PVC, CPVC, or PEX, as fittings are designed specifically for each type. Then, assess the temperature and pressure requirements of the application to ensure the fittings can withstand them. Consider the size and configuration needed, ensuring compatibility with the existing piping system. Finally, check for any additional requirements like chemical resistance or UV resistance, and consult industry standards and guidelines to make an informed decision.

- Q: How are plastic pipe fittings manufactured?

- Plastic pipe fittings are commonly manufactured through various processes such as injection molding or extrusion. In injection molding, melted plastic is injected into a mold cavity, cooled, and then removed as a solid fitting. Extrusion involves pushing melted plastic through a die, shaping it into the desired fitting profile, and then cooling it down. Both methods allow for the production of precise and durable plastic pipe fittings.

- Q: Can plastic pipe fittings be used in irrigation drip systems?

- Yes, plastic pipe fittings can be used in irrigation drip systems. Plastic fittings are commonly used in drip irrigation systems due to their durability, affordability, and ease of installation. They are resistant to corrosion, provide a tight seal, and can withstand the pressure and flow rates required for efficient irrigation.

Send your message to us

Plastic Waste Pipe and Fittings PPR Pipe Fitting for Hot or Cold Water Brass Ball Valve High Class Quality Standard from China New

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords