Geotextil Tejido Precio Nonwoven Split Joint Fabric/Nonwoven Weed Barrier Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

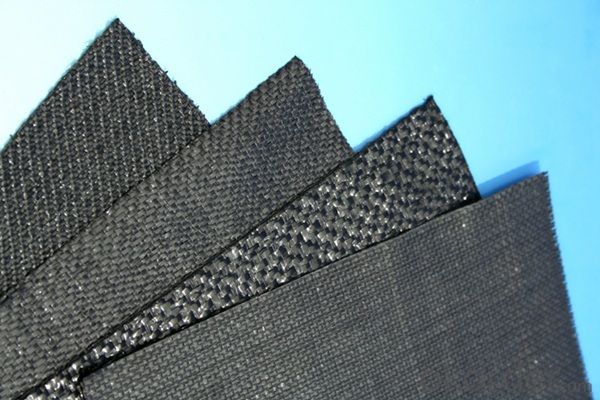

Weed Control Fabric Product Description

Weed Control Fabric is also known as weed control mat, anti grass cloth, ground cover, weed barrier, it is woven by polyethylene or polypropylene material. It is mainly used for ground weed prevention in the green house, drainage, maintain ground clean, ground mark and agricultural guidance, road surface protection and so on.

Weed Control Fabric Specification

Product Name | Weed Control Fabric |

Materials | 100% PP or 100% PE |

Weaved Condition | By circular jet loom or water looms |

Width | 0.5m to 6m (1.64ft to 19.69ft) |

Length | Made to the order (Customized available) |

Weight | 70g/m2 to 400g/m2 |

Mesh | 8x8; 10x10; 11x11; 12x12; 12x16; |

Colors | Black, Green, White etc. (Customized available) |

UV Protection | 2 years, 5 years, or more |

Application | Green House; Garden; Landscape; Road surface protection; Seedbed protection; Grass control etc |

Weed Control Fabirc Features

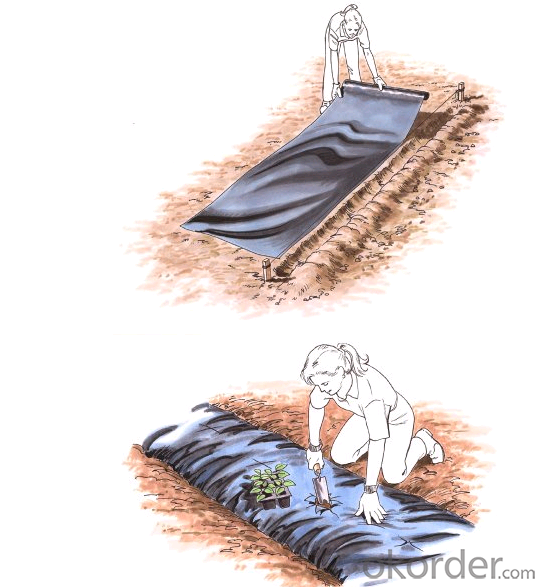

1. Weed suppressant and drainage control landscaping fabric

2. Easy to use, Environmentally friendly

3. Allows water, air and nutrients through, suppressing weeds without the use of chemicals

4. Reduces the level of watering required due to the slower rate of water evaporation

Weed Control Fabric Application

1. Excellent Weed Control

2. Moisture, fertilizers, air reach plants to allow for healthy soil

3. Good water and air permeability

4. Exceptional toughness and strength

5. Durable, tear-resistant; won't rot or mildew

6. Lightweight, easy to install, follows natural ground contours

7. Ideal for use in landscaped beds, under decks and walkways.

Packaging & Delivery

| Packaging Details: | Packed In Roll Or In Bales Or Cartons Or According To Customers Requirement |

| Delivery Detail: | 20 Days After Order Confirmed |

- Q: In ANSYS, geotextile what unit to simulate it?

- The use of shell units is relatively more reasonable.

- Q: How do geotextiles help with erosion control on slopes?

- Geotextiles help with erosion control on slopes by providing a protective layer that stabilizes the soil, prevents erosion, and promotes vegetation growth. They act as a barrier against water and wind, reducing the velocity of runoff and minimizing soil erosion. Additionally, geotextiles help to retain soil particles while allowing water to pass through, preventing the loss of soil and promoting the establishment of vegetation, which further enhances slope stability.

- Q: How do geotextiles improve the performance of asphalt overlays?

- Geotextiles improve the performance of asphalt overlays by providing reinforcement and separation between the existing pavement and the new asphalt layer. These fabrics help distribute the load and prevent the mixing of materials, reducing cracking and increasing the overall durability and lifespan of the overlay.

- Q: Can geotextiles withstand harsh weather conditions?

- Yes, geotextiles are designed to withstand harsh weather conditions. They are made from durable materials that are resistant to UV rays, moisture, and temperature fluctuations, making them suitable for various environmental conditions. Additionally, geotextiles have high tensile strength and can resist damage caused by heavy rain, wind, and extreme temperatures, ensuring their performance and longevity even in harsh weather conditions.

- Q: Can geotextiles be used in shoreline protection?

- Yes, geotextiles can be used in shoreline protection. They can help to stabilize soil and prevent erosion by acting as a barrier against water, while still allowing proper drainage. Geotextiles can also help to reinforce and protect shoreline structures such as retaining walls or revetments.

- Q: Are geotextiles cost-effective?

- Yes, geotextiles are cost-effective. They offer numerous benefits such as erosion control, soil stabilization, and filtration, which can reduce the need for expensive repairs or replacements of infrastructure. Additionally, geotextiles are typically easy to install and require minimal maintenance, further contributing to their cost-effectiveness.

- Q: What are the specifications for geotextiles in green roof applications?

- The specifications for geotextiles in green roof applications typically include requirements for strength, permeability, UV resistance, and root resistance. These geotextiles need to be strong enough to withstand the weight of the green roof system and any potential loads, while also allowing water to drain through and preventing soil erosion. UV resistance is important to ensure the geotextile can withstand prolonged exposure to sunlight without degradation. Additionally, geotextiles used in green roofs should have root resistance properties to prevent plant roots from penetrating and damaging the underlying structure.

- Q: What are the key considerations for geotextile installation in cold climates?

- There are several key considerations for geotextile installation in cold climates. First, it is important to choose a geotextile material that is specifically designed for cold weather conditions. This ensures that the material will not become brittle or easily damaged in freezing temperatures. Additionally, proper site preparation is crucial, including removing snow and ice from the installation area to ensure a stable base for the geotextile. It is also important to properly anchor the geotextile to prevent shifting or movement due to freeze-thaw cycles. Overall, careful selection of materials and proper installation techniques are essential for successful geotextile installation in cold climates.

- Q: Concrete maintenance with geotextile, Tonglu how to buy

- Huazhi geotextile material manufacturers

- Q: Geotextile construction inspection batch ye do?

- Willing to smash the acceptance of smashing acceptance in vain

Send your message to us

Geotextil Tejido Precio Nonwoven Split Joint Fabric/Nonwoven Weed Barrier Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords