Ni-P Alloy Grooved Drum for Automatic Winder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

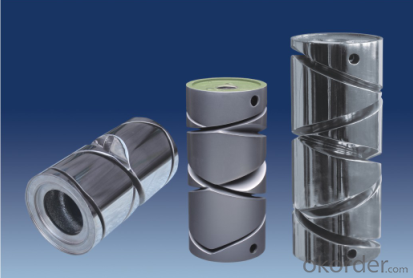

Structure of Ni-P Alloy Grooved Drum for Automatic Winder:

1. Best groove curve, ultra-fine processing, mirror polished surface, and high smooth finish(Ra<0.2μm).

2. We plating Ni-P on the surface;coating has high density,small crystallization , low porosity.Drum groove has complete coverage of coating, and the coating has good uniformity, excellent corrosion resistance.

3. Ni - P alloy coating is dealing with aging hardening and high temperature heat treatment. The hardness of the surface of Ni-P grooved drum can reach HV1100; it has the advantages of high wear resistance, high toughness, and low internal stress.

4. Higher wear resistance, higher corrosion resistance, higher uniformity, and longer life cycle.

Main Features of the Ni-P Alloy Grooved Drum for Automatic Winder:

Best groove curve, ultra-fine processing, and high smooth finish(Ra<0.2μm).

Highly accurate, mass-radius product is less than 10g·mm, and the linear velocity can reach 2000m/s.

High wear resistance, corrosion resistance.

Coating has high density,small crystallization , low porosity.

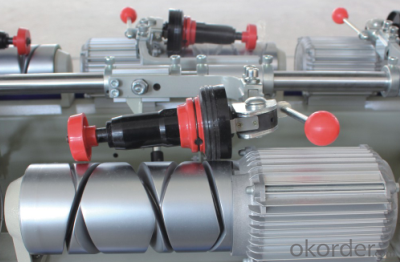

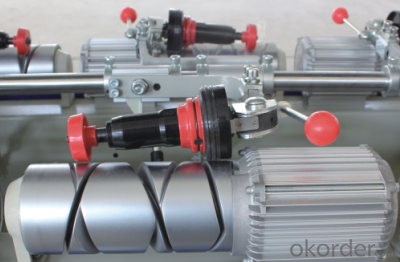

Images of Ni-P Alloy Grooved Drum for Automatic Winder:

Models of Ni-P Alloy Grooved Drum:

Model | Groove number of turns | Lead | Aperture | Outer diameter | Length | Package angle |

CT-B | 2.5 | 154 | φ20 | φ82 | 176 | 0° |

CT-S | 2.5 | 147 | φ20 | φ82 | 183 | 0° |

CT-S1 | 2 | 150 | φ20 | φ95 | 176 | 0°—3°30′ |

CT-J | 2.5 | 152 | φ20 | φ82 | 176 | 3°30′—5°57′ |

Packaging & Delivery of Ni-P Alloy Grooved Drum:

Packaging Detail: Wooden case or as per customers' requirements

Delivery Detail: 5 days from receiving the advance payment

FAQ of Yarn Winding Machine:

1. Q:What is the machine used for?

A:Vertical Soft Yarn Winder is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

2. Q: What is the MOQ?

A: 100 pc.

?3. Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: Why the first industrial revolution in the cotton textile industry innovation will cause the British national yarn shortage?

- After the invention of the shuttle and widely used, cotton yarn in short supply. According to the workshop when the textile industry is very developed Manchester statistics, five or six spinning spun yarn, only for a weaving day. Cotton yarn shortage, yarn shortage and other issues restrict the rapid development of the textile industry. The revolution of the textile machinery forced the revolution in the loom to push the textile machinery revolution

- Q: What is the second-hand textile machinery import clearance process?

- 1. Used equipment, but to maintain its basic use value or the full use value

- Q: What are the high efficiency of the spinning machine and the Jenny spinning machine of the invention?

- The earliest use of hydraulic spinning machine is horsepower driven, and later cited hydraulic. The use of hydraulically operated machines is of great importance in the history of the textile industry, where textile workers can operate the machine at hand, but once the power is used, the worker can not leave the power source, As the beginning of the factory system. The first batch of factories in history was established to make textiles. In 1779, S. Crompton, in conjunction with the advantages of the Jenny spinning machine and the hydro spinning machine, developed a spinning mule that spun out fine and strong spun yarns,

- Q: What is the current status of the textile industry?

- The global textile industry market uncertainty is increasing, which with the global credit crisis and the United States, the EU economic growth slowdown in the trend will bring impact on the clothing retail industry. The dollar outreach, crude oil prices ups and downs and China's textile exports to Europe will lift the limit, are declared a major change. By the US economic slowdown, corporate sales will decline. And because the United States, Europe may implement new trade barriers, so the global textile industry procurement may be a significant change in the trend. In addition, there are less than 3 months, for the textile and apparel products quota system will end. This international textile and apparel trade system changes are the latest challenges faced by textile and garment enterprises, not only with hope and opportunity, but also with a great risk.

- Q: When the textile industry, as well as the history of the textile industry development?

- Ancient countries in the world for the textile fibers are natural fibers, usually wool, linen, cotton) three short fibers, such as the Mediterranean region before the textile fiber is only wool and linen; India Peninsula region before the use of cotton

- Q: What are the risks of safety accidents in the textile machinery industry?

- The Fourth, in the exposed parts of the drive did not take security measures.

- Q: What is the history of the development of textile machinery?

- Human beings originally used natural fibers as raw materials for spinning and weaving, earlier than the invention of the text (see World Textile History, China Textile History).

- Q: Why did the first industrial revolution begin with the sign of Jenny's textile machine rather than shuttle?

- The innovation of the British cotton industry began in 1733 when the mechanic John Kay found that the shuttle was the sign of the industrial revolution, but was narrow and limited to light industry.

- Q: Textile machinery production process is probably what kind of?

- And then the processing of a good machine frame is the initial installation of the wall after the installation (here first to do the foundation).

- Q: What is the structure and working principle of Jenny's spinning machine?

- Spinning a hand when a small section of cotton yarn hook on the hook on the spindle, and then pull a sliver and cotton yarn caught, twisted in the hands. So that this piece of cotton bar was hooked with the handle fixed. This is called on both sides of the spinning grip, hand cranks on the small wheel to drive the spindle on the rotation called twisting.

Send your message to us

Ni-P Alloy Grooved Drum for Automatic Winder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords