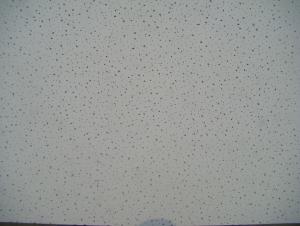

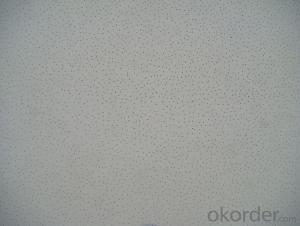

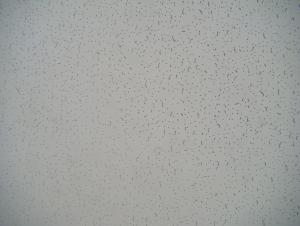

15mm Mineral Fiber Ceiling Tiles MA04

- Loading Port:

- Xingang China

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 1×40HQ m²

- Supply Capability:

- 3×40HQ per day m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Standard Size: 595mm*595mm, 605mm*605mm

Standard Thickness: 9, 10, 12, 14, 15, 18mm

Edge Detail: Square Edge, Tegular Edge (≥12mm)

Technical Data of Mineral Fiber Ceiling:

Density: 260-320kgs/m3

NRC: ≥0.50

Fire resistance: Class B1 (standard GB 8624-1997)

Moisture rate (%): ≤3.5 (40℃,70%RH)

Light reflect: 0.70-0.80

Sagging resistant properties: ≤0.35mm

Humidity Resistance: ≥85%

Typical Application Areas of Mineral Fiber Ceiling:

Hotel Lobbies and Corridors

Offices and conference rooms

Department stores

Super Malls

Hospitals and other Public areas

Standard Thickness: 9, 10, 12, 14, 15, 18mm

Edge Detail: Square Edge, Tegular Edge (≥12mm)

Technical Data of Mineral Fiber Ceiling:

Density: 260-320kgs/m3

NRC: ≥0.50

Fire resistance: Class B1 (standard GB 8624-1997)

Moisture rate (%): ≤3.5 (40℃,70%RH)

Light reflect: 0.70-0.80

Sagging resistant properties: ≤0.35mm

Humidity Resistance: ≥85%

Typical Application Areas of Mineral Fiber Ceiling:

Hotel Lobbies and Corridors

Offices and conference rooms

Department stores

Super Malls

Hospitals and other Public areas

- Q: 10 points who ever answers

- Roof tiles are designed mainly to keep out rain, and are traditionally made from locally available materials such as clay or slate. Modern materials such as concrete and plastic are also used and some clay tiles have a waterproof glaze. or did you mean interior ceiling tiles? ; They are fabricated from perlite, wood, mineral wool, plastic, tin, aluminum, and fibers from recycled paper. They frequently have patterns comprised of holes, to improve their sound absorption properties, though many have a molded surface providing a textured, sculptered or pressed-tin look to the ceiling.

- Q: Instead of wallpaper decorative materials

- 1 Lightweight High strength This is the most significant and important feature of wood. Under normal circumstances the apparent density of wood 550kg / m3 but its compressive strength and bending strength of the wind are about 100Mpa so the high specific strength of wood is a lightweight high-strength materials with high value. 2 wood unique structure.

- Q: Old BMW 5 Series door trim how to dismantle?

- Only two or three screws are the same glue nails

- Q: Indoor wall decoration board like wood flooring is what kind of material

- Generally is the wooden floor, the wall is best to have a small keel or a large core board used to fix the wood floor. Can not be used with mosquito nail guns. Hand fee of about 20 yuan a square meter

- Q: Cheetah cs6 bumper trim plate

- Hello, generally on the Internet, Auto Parts City and 4S shop are sold, if my answer to your help, please set as the best answer, thank you for your hands!

- Q: Uv decorative board is what?

- The so-called uv decorative plate, which refers to its surface after UV curing paint protection treatment of a new environmentally friendly decorative materials, its substrate contains cement pressure board, solid wood multilayer board, MDF, glass magnesium fire board four. Uv decorative plate surface after a special treatment more smooth and smooth, wear resistant, resistant to corrosion, heat and cold, excellent performance, very popular in the market.

- Q: Insulation decorative board can save energy for the building how much

- Jinkma metal exterior insulation decorative plate consists of three parts, the surface layer of galvanized steel plate (high quality aluminum alloy plate), the surface selection of high weather special coating, the special coating process, according to the need to paint the surface of different colors, and then The special metal embossing equipment rolled into different patterns, and after repeated painting, the formation of a variety of color relief three-dimensional pattern. Can meet the architectural shape and color appearance requirements, to achieve a certain artistic effect. The middle layer is made of flame retardant stainless high density polyurethane foam. Different regions can choose different foam thickness of the insulation decorative plate. The bottom of the different needs of customers moisture, insulation, fire-retardant aluminum foil, high-quality steel plate protective layer.

- Q: Put the sound when the decorative board is abnormal where is the fault?

- That off a line of the problem, such as: off the zero line, the two lines are the phenomenon of FireWire, such as broken FireWire. On the two are no electricity, simply said. Electricity rate of 50 per second, broken a line, no circuit.

- Q: How can be fixed in the pvc decorative panel roof racks!

- First with a screw to the plywood and other fixed on the ceiling, and then the drying rack installed on the plywood

- Q: Uv imitation marble decorative plate belongs to what material

- (1) scraping does not spend, pollution does not dye, burning does not hurt, anti-aging, non-toxic without radiation. (2) color and diverse, do not change color does not fade, long service life. (3) acid, alkali, high temperature, good weather resistance, waterproof, fire, moth, anti-mold. (4) compact structure, strong anti-fouling, easy to clean care, can maintain a lasting gloss, bright as new. (5) from environmentally friendly raw materials, according to the requirements of processing into a plane, arc and other shapes.

SERENITY,is a large company which produces light mineral wool acoustic board. It displays a good combination of production , manufacture, supporting sales and international trade.Its products cover more than twenty varieties of six categories, including knurling board, relief-embossing board, printing board, spraying board, stereo-molding board, etc.

1. Manufacturer Overview

| Location | Jinzhou,China |

| Year Established | 2006 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | Japan, Italy, South- Africa ,India, Russia, Malaysia, Singapore, Taiwan and other countries and areas |

| Company Certifications | ISO9001-2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | TIANJIN |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

15mm Mineral Fiber Ceiling Tiles MA04

- Loading Port:

- Xingang China

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 1×40HQ m²

- Supply Capability:

- 3×40HQ per day m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords