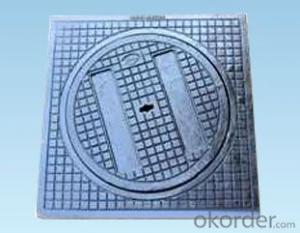

Manhole Cover with Square Base Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Ductile Iron Manhole Cover Description :

A manhole cover is a removable plate forming the lid over the opening of a manhole, to prevent anyone or anything from falling in, and to keep out unauthorized persons and material.

A manhole cover sits on metal base, with a smaller inset rim which fits the cover. The base and cover are sometimes called "castings", because they are usually made by a casting process, typically sand-casting techniques.

2.Main Features of the Ductile Iron Manhole Cover:

Safety options

There is no metal contain, directly reducing potential accident or further maintenance costs caused by thieves. Anti-slip surface offer a safe road condition even in extreme weather.

Light weight

Compared with cast iron manhole cover, FRP manhole cover is 30% lighter.

Light weight allows more loading per vehicle, more convenient transportation and economical savings.

Allows a safer working condition, which single workers is enough for installation without risk of injury.

Long service life

Strong resistance of acid, alkali, weathering, anti corrosion of water, dust, manhole covers used for gas are well sealed which prevent poisonous gas leaking.

Temperature tolerance is at the range of -40°C-200°C.

Manholes allow access to underground pipes, cables, meters and facilities.

BS EN124 Standard:

A15: Area which can only be used by pedestrians and pedal cyclists.

B125: Footways, pedestrian areas and comparable parks or car parking decks.

C250: For gully tops installed in the area of curbside channels of roads.

D400: Carriage ways of roads(including pedestrian streets), hard shoulder and parking areas, for all types of road vehicles.

E600: Areas of imposing high wheel loads, e.g. dock and aircraft pavements

3.Manhole Cover Images:

4.Manhole Cover Specifications:

1) Production information

Manhole cover are manufactured for construction and public use. Manhole cover shall be smooth and free sand holes, blow holes, distortion or any other defects

2) Material

A) Ductile iron GGG50

B) Grey iron GG20

3) Designs

A) EN124 Class B125 C250 D400 F 900, with different size and grammage, or as customers' requirement.

B) as per customers' drawing or samples

4) Process

A) Molding boards

B) Hand Casting

5) Coating

A) black bitumen or epoxy .

B)Coating as per customer's requirement

6) Different accessories are available

7) Packing:

Wooden case or wood pallet, or as per customers' requirement

8) Payment terms: T/T or L/C

5.FAQ:

Q. Odours are coming through where I have installed my manhole cover, why?

A. Your cover must be sealed and locked, or neoprene sealed, so you would require a T-Range Cover, or if you require a solid top, a selection of the PC range (e.g. PC2BG3, PC6CG3, not PC2BG) are suitable.

Q. I need access through my manhole cover on a regular basis, is this possible?

A. Yes, the majority of covers have built-in lifting keys, and for those that don’t we also supply lifting keys. However, the best way to obtain easy access is to have a bespoke, hinged manhole cover.

- Q:Nominal diameter 12 washers, outside diameter?

- at present our country flat washer implement related standards are as follows:

- Q:Gasket A140 what is the material

- Gasket A140 is stainless steel, used in corrosive media environment to do flat washers.Gasket introduction:A part between a connector and a nut. A flat metal ring is generally used to protect the surface of the connecting piece from the nut.Classification:The washer is divided into: -C, flat washer washer -A and grade C, grade -C large washers, washer, flat washer, flat washer, chamfered - - a grade steel structure with high strength washer, spherical washer, taper washers, square taper washers, steel I-beam, square taper washers standard type spring washers, spring washers, light heavy spring washers, lock washers internal teeth serrated lock washers, inner and outer teeth lock washers, serrated lock washers, single ear washers, ears washers, external tab washers, round nuts with washers.

- Q:Why do you have to add a spring washer when it comes to the role of ah ah ah

- If the screw on a spring washer, screw and screw hole fixed, due to the role of the spring washer spring will greatly reduce the possibility of loosening screws, falling off

- Q:how to Flat washer installation

- Flat washers are used on both sides, are required to install.

- Q:What are the advantages and disadvantages of car audio modification, wood washer and plastic washer?

- The plastic washer is made of plastic, plastic washer at home, also known as plastic washers, washers (Washers) resin, plastic washer or nylon washer (the most common domestic market is mostly made of plastic washer nylon 66). Compared with metal gaskets, it has excellent insulation, corrosion resistance, thermal insulation and non magnetic properties, and light weight, widely used in semiconductor, automotive, aerospace industry and interior decoration and other fields. The number of materials used as many as 10 kinds, including PA66, PC, with the best performance of special engineering plastics PEEK, with glass fiber reinforced RENY and PPS, fluorine resin PTFE, PFA and PVD, etc..Wood washer to prevent resonance, but not waterproof.

- Q:Thank you for your support

- If you ask this question if it is to lock up, then want to effect a little better, it is recommended to use double-sided tooth lock washer, I can give you the price of understanding, Baidu my user name!

- Q:In the design, the bolt connection is necessary to have a gasket?

- The bolt must not install gasket, join many planes and automobiles and ships, wind turbines, atomic energy equipment is not installed gasket, everywhere is whether heavy vehicles or small bolts on the wheel without gasket. Gasket is the name of the washer, flat washers, special washers, spring washers, washers, washers. Installed not installed gasket, what gasket, depending on the specific design requirements, to have the basis of choice. In general, the position of the bolt hole is very high, the bolt hole diameter is relatively small, with close to that level of reaming hole, install flat washer is unnecessary, it does not have the nut friction. For those with very rough hole bolt connection, such as with M12 bolt hole diameter of 16mm, 18mm, it should be installed flat washer. This connection is often a lap of the steel frame, the location of poor manual drilling equipment. The automobile gear box is usually a hole on the production line and the position of the hole is high, and the bolt hole with the gap is relatively small, do not install the washer, otherwise the smaller contact area of the nut, the bolt is easy to loose.

- Q:How to use washer, gasket, o-ring "

- Three are used to enhance the sealing performance of the accessories, in general:Washer gasket, a uniform thickness of the ring, used in the bolt to enhance the connection between the fastening; gasket gasket, a variety of shapes, for a variety of occasions, enhance the tightness. In general, both are metallic and washer is included in the category of gasket.Liner and O-ring are commonly referred to as sealing ring, rubber material, shaped like a mini version of the buoy, but the wall thickness is larger and better elasticity, mainly used for instrument installation in Glen head.

- Q:Gasket 300HV relative to what material?

- For the 140HV level can choose 08F, 08Al and 10, 10F, etc., the surface hardness can reach about 140HV

- Q:how to use Motor washer

- Halo, brother, your question also detailed ah, there are a lot of places on a motor washer ah, do you mean where ah, you have to iron or plastic washers, spring washers, I think it is the plastic washer, mainly plastic washer 1 are leak proof, waterproof, anti oil,... 2 insulation, high pressure resistance, 3, vibration reduction, 4, reduce wear, basically on these several functions

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Manhole Cover with Square Base Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products