Machine for Concrete Floor Slab with Holes

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Machine for Concrete Floor Slab with Holes

1. Structure of Machine for Concrete Floor Slab with Holes:

Machine for Concrete Floor Slabs with Holes works on the long-line table, using the high-strength low-relaxation steel strand as the guide, using the pushing work method to forming the concrete hollow-core slab. The slab have the advantages of smooth surface, high-density structure, capable of making construction slabs of 4.2m to 18m. The GLY series concrete hollow-core slab mainly used on the larger bay workshop, school, hospital, shopping mall, office building, bulk storage plant etc.

2. Main Features of Machine for Concrete Floor Slab with Holes:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

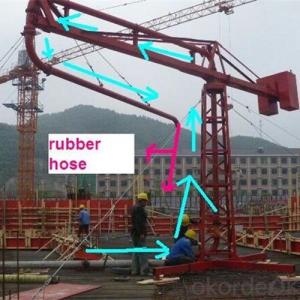

3. Machine for Concrete Floor Slab with Holes Images:

4. Machine for Concrete Floor Slab with Holes Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Process

Rebar tensioning

Raw materials preparing

Molding

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

7. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: What are the specifications of concrete spreader?

- A counterweight box is arranged on the balance frame. It settled in the main beam rear connecting flange, screw firmly, to ensure the stability of the incident

- Q: What is the difference between concrete pump truck and concrete distributor in construction?

- Automobile pump flexible tubing can flexibly rotate 360 degrees, the body shift is also very convenient, the pumping efficiency is relatively high, but the cost is more expensive.

- Q: How to install and use the distributor?

- In the process of assembling and installing concrete distributing machines, the constructors must wear safety belts when they work at high altitude, and the seat belts must be hung where they can be stressed. Construction cable must be overhead or buried in the ground, not flat and put

- Q: How to fit the cloth rod of the distributor?

- Build a frame with a cloth pole for bearing and inspect and check the bearing capacity of the stressed part, the reinforcement condition of the double fasteners and the stability of the foundation

- Q: What do concrete pumps and fabrics mean?

- People need to arrange for pouring concrete tubing, split pipe, guard, pump handle up too much trouble

- Q: What is the working principle of the distributor?

- In order to ensure the safety of the work procedure, prevent the cloth machine from tipping over and pay attention to the stability of the frame of the distributing machine, the construction can be carried out

- Q: How to maintain the concrete spreader?

- The spiral blade edge of the cloth is inlaid with welded alloy wear-resistant blocks, and the spiral shaft can be operated normally for 10 months. The spiral shaft is designed to be easy to assemble and disassemble

- Q: What is the structure of a concrete distributor?

- A composite movement consisting of two parts of a rotating frame covers all cloth radius points

- Q: What is the concrete distributor?

- A composite movement consisting of two parts of a rotating frame covers all cloth radius points

- Q: What's the design plan of the concrete spreader?

- Hinge structure on the tape machine design by two light truss, is hinged on the frame of the rotary hopper, through a hinged cylinder between two truss angle adjustment according to needs; in the lower part of the tape machine, design a universal wheel, can move along the axial cylinder in truss drive, adjustable belt tail height

Send your message to us

Machine for Concrete Floor Slab with Holes

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords