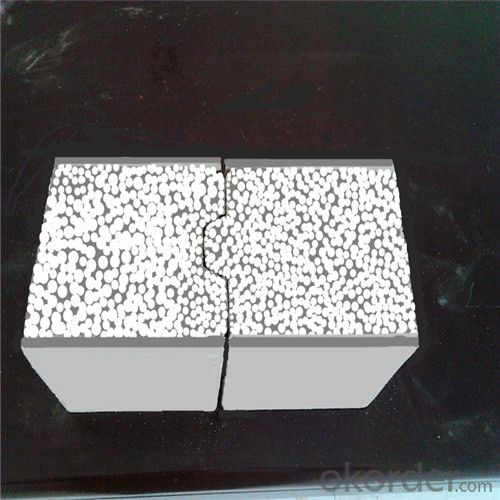

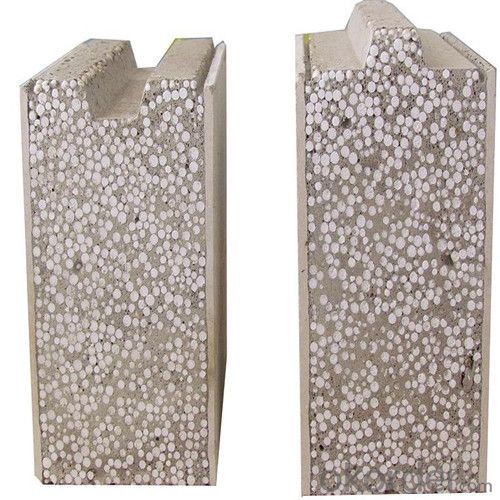

Light weight concrete sandwich panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiber cemnt sandwich panel, light weight concrete sandwich panel

1. Composition:

Core materials: cement, EPS, and fly ash core

Surface materials: fiber reinforced calcium silicone board or cement calcium silicone board

2. Specification: (L*W*T)

1500-3000mm X 610mm X (50, 75, 100, 120,150,180mm)

fiber cement board on both sides: 5mm, 6mm, 8mm

3. Usage:

Interior and exterior partition on steel or concrete structure building,

For new construction, additions or renovations.

4. Advantages:

Energy-saving

Light weight

Sound insulation

Environmental protection

Most area-saving

Most waterproof and dampproff

Most fire-proof

Most sound-insulation

Best hanging force

Most anti-seismic and impact resistance

Largest span and height thin webbed wall

Most civilized, environmental, high efficiency construction.

- Q: OKorder Wang Teng color steel production and sales of a variety of color steel plate, Caigang tiles, Caigang rock wool sandwich panels, Caigang polyurethane sandwich panels, Caigang foam sandwich panels, Caigang extruded sandwich panels, color Steel paper honeycomb sandwich panels, galvanized sheet, floor board, Caigang sandwich panels, C steel, color steel activities, and other products.

- Energy-saving insulation: thermal insulation superior performance, the same thickness of the insulation effect is 2 times the EPS board. ? Flame retardant: The product has passed the "National Fixed Fire Extinguishing System and Refractory Component Quality Supervision Center", the combustion level to GB8624 B2 level standards. ? Sound insulation: sound absorption is good, on the rain, hail and other impact caused by the sound has a subtractive effect. ? Waterproof rust: a large span, fast drainage, waterproof effect is good; screw hidden, easy to rust, to extend the useful life of the plate. ? Beautiful economy: beautiful appearance, rich colors; reduce material loss, save construction time and project costs. ? Construction of fast: polyurethane sheet is a highly controlled plant in the factory environment, the quality of production, quality and stability; construction fast, the application has more than 35 years.

- Q: Solid wood particle board to do wardrobe, shoe cabinet, cabinet how, environmental protection index is not high, long life is not long?

- Solid wood particle board is actually "particleboard", environmental protection index E2 or E3 level (E0 level 0 formaldehyde emissions). Life is not sandwich board length, lighter than the density board, grip nail is poor

- Q: Density board, sandwich panels, solid wood particle board What is the difference between the three, which is better!

- Sandwich board ah light weight, fast construction. Environmental protection, green, recyclable

- Q: Aluminum magnesium manganese composite sandwich panel 90 degrees right angle how to fold

- Certainly the aluminum magnesium manganese plate light, the proportion of aluminum magnesium manganese plate is 4.71, the proportion of color steel plate is 7.85.

- Q: Rock wool sandwich panel price rock wool sandwich board how much money a square meter

- This depends on the weight of rock wool, as well as color steel kind. If you need, we plant production. This answer is provided by Hebei Chengxin chemical building materials, if satisfied please adopt.

- Q: Color steel sandwich board where the best quality?

- To see where you are, too far away from the good cost is also high, the best distance from the nearest, I was Xuzhou people, I think before the company in the Pepsi Steel made Bo Sige plate is very good,

- Q: 100 thick roof color steel foam sandwich panels how to calculate the weight

- You calculate 1 square meters wide inside and outside the two thin steel plate added to the foam core weight, the number multiplied by 10, is the bulk density, its unit is ㎏ / m?. Or, weigh each block to remove each area, then multiplied by 10, is the bulk density.

- Q: what is sandwich panel?

- I think you are talking about a sandwich board - which is two large panels of cardboard, held together by strings over a person's shoulders and used to advertise on the street. Restaurants often hire someone to stand in the street wearing a sandwich board to advertise for the daily special and hand out flyers.

- Q: Share what is color steel sandwich panels, what are the characteristics and applications

- Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. Sandwich panels are a common product in the current building materials, not only good flame retardant and environmentally friendly Sandwich board English name: laminboard Sandwich panel products are composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the composition of the polymer core insulation. These sandwich panels are easy to install, lightweight and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. [1] The formation of the outer steel plate takes full account of the structural and strength requirements, and take into account the aesthetic, the inner layer of the formation of flat to meet the needs.

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- Polyurethane is a two-component AB material (isocyanate and combined polyether) mixed foam, is the thermal insulation material in the lowest thermal conductivity of 0.017 ~ 0.024 (thermal conductivity of the lower the better insulation). Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use. If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation. The cost is still lower than the infusion process.

Send your message to us

Light weight concrete sandwich panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords