Corporate Packaging Tape - Light Duty Adhesive Masking Tape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 roll

- Supply Capability:

- 30000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General purpose of Light Duty Packaging Adhesive Masking Tape

1) good adhesive

2) good flexibility

3) No residual left

4) Different sizes are available

Feature of Light Duty Packaging Adhesive Masking Tape

general purpose masking tape, adhesive tape, paper tape.

1) good adhesion. 2) good flexibility.

-General purpose masking tape is made of crepe paper coated with natural rubber adhesives.

-It is designed for interior paint masking, light-duty packaging, holding, bundling, splicing and packaging.

-Practical for construction, building, home, office or industrial applications.

-Jumbo roll, log roll and cut roll are available.

-The width of jumbo roll is from 980mm - 1250mm

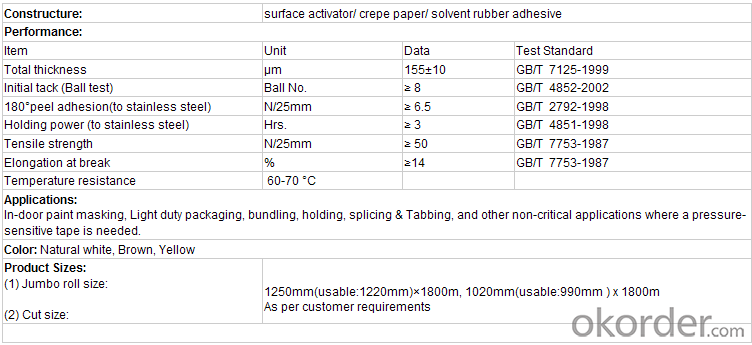

Specifications of Light Duty Packaging Adhesive Masking Tape

Advantages of Light Duty Packaging Adhesive Masking Tape

Different temperature resistance with good adhesion

High tensile strength, good resistance of damage, no residue, eco-friendly

Accept custom design

SGS, ISO, BV, CTI certificates approved

Professional teamwork for orders

No.267 on the 2014 Fortune Global 500

Professional manufacturer with 31 years experiences of adhesive tapes

Special size, color can be made according to customer's requirement.

Our Services

Your inquiry related to our product & price will be replied within 24 hours.

Well-trained & experienced staff can answer all your inquiries in English or other language

Your business relationship wit us will be confidential to any third party

Good after-sale service offered please free feel to contact us for more information

FAQ

Q 1: Do you have any MOQ of Wonder Masking Tape?

A: Yes, according to the size you need.

Q 2: What is the delivery time?

A: Sample time 7 days, 30 days for the mass production.

Q 3: Can we put our logo on the products?

A: Yes, welcome.

Q 4: How should I pay for you if I place order to you?

A: Usually, 30% T/T deposit in advance, 70% balance against the copy of B/L.

- Q: Is packaging tape easy to cut with scissors?

- Yes, packaging tape is typically easy to cut with scissors.

- Q: Can packaging tape be used for sealing fabric or textiles?

- No, packaging tape is not suitable for sealing fabric or textiles as it may not adhere properly and could damage the material. It is recommended to use fabric-specific or textile adhesive tapes for this purpose.

- Q: What are the benefits of using pre-printed packaging tape with warning messages?

- There are several advantages to using pre-printed packaging tape with warning messages. To begin with, it increases safety by clearly informing handlers of potential package hazards. These warning messages can include instructions like "Fragile," "Handle with Care," or "Do Not Stack," which prevent mishandling and reduce the risk of damage during shipping or transportation. By providing this crucial information upfront, pre-printed packaging tape ensures that fragile or sensitive items are handled properly, decreasing the likelihood of breakage, leakage, or other accidents. Additionally, it saves time and effort because the warning messages are already printed on the tape. This eliminates the need to separately apply warning labels or write instructions on the package, streamlining the packaging process. It also reduces the chances of labeling errors or inconsistencies since the pre-printed tape ensures a standardized and professional appearance. Moreover, using pre-printed packaging tape with warning messages enhances brand image and customer satisfaction. It demonstrates a dedication to quality and safety, which positively influences customer perception. It also helps establish trust and confidence in the company's products or services since customers can see that proper precautions are being taken to ensure the secure delivery of their items. Lastly, pre-printed packaging tape with warning messages can serve as a marketing tool. By incorporating the company logo, contact information, or promotional messages on the tape, businesses can effectively promote their brand and leave a lasting impression on customers. This increased visibility can boost brand recognition and potentially attract new customers. In conclusion, using pre-printed packaging tape with warning messages offers numerous benefits, including improved safety, time and effort savings, enhanced brand image, and marketing opportunities. It is a practical and efficient solution for businesses seeking to guarantee the secure and efficient transportation of their products.

- Q: Are there specific brands of packaging tape that are recommended?

- Yes, there are specific brands of packaging tape that are commonly recommended for their quality and reliability. Some popular and highly regarded brands include Scotch, Duck, 3M, Gorilla, and Uline. These brands are known for producing packaging tapes that have strong adhesive properties, excellent durability, and the ability to securely seal boxes and packages. Additionally, these brands often offer a variety of options such as different widths, lengths, and types of tape (such as clear, colored, or reinforced) to suit various packaging needs. However, it is always recommended to consider the specific requirements of your packaging task and read customer reviews before choosing a brand of packaging tape.

- Q: What are the considerations for using packaging tape on fragile items like ceramics?

- When using packaging tape on fragile items like ceramics, there are several important considerations to keep in mind. Firstly, it is crucial to select the appropriate type of packaging tape. Look for tape that is specifically designed for fragile items or delicate surfaces, as it will typically have features such as gentle adhesive and high tensile strength. This type of tape is less likely to damage or leave residue on the ceramics. Secondly, it is important to handle the ceramics with care when applying the tape. Avoid applying excessive pressure or force that could potentially cause them to crack or break. Additionally, make sure to clean the surface of the ceramics before applying the tape to ensure proper adhesion. Another consideration is the amount of tape that should be used. While it is important to secure the ceramics adequately, using too much tape can add unnecessary weight and potentially damage the fragile item. It is advisable to use just enough tape to hold the ceramics securely in place without putting excessive strain on them. Furthermore, it is recommended to use additional protective materials in conjunction with the packaging tape. Bubble wrap, foam sheets, or packing peanuts can provide extra cushioning and protect the ceramics from any potential impact or vibrations during transit. Lastly, it is crucial to label the package as fragile to ensure that handlers are aware of the delicate contents. This can help to minimize the risk of mishandling and provide an extra layer of caution during transportation. In conclusion, when using packaging tape on fragile items like ceramics, it is important to choose the appropriate type of tape, handle the ceramics with care, use the right amount of tape, employ additional protective materials, and clearly label the package as fragile. By considering these factors, you can help to ensure the safe transportation of your fragile ceramics.

- Q: For the moment the yellow rubber stamp [] how to use paper and pen, pen parts packaging tape?

- Circle, circle, lap, wrap the tail and cut off the excess!

- Q: Can packaging tape be used for other purposes besides packaging?

- Packaging tape is not limited to packaging; it can be utilized for various purposes. With its strong adhesive properties and durability, it serves a multitude of functions. For instance, it proves useful in household repairs like mending broken book spines or securing loose cables. Moreover, it finds its place in crafting projects, allowing the creation of temporary or permanent decorations, durable envelopes, and even makeshift labels or item organization. Additionally, it comes in handy for quick fixes, like sealing small leaks or cracks in pipes or containers until a more permanent solution is discovered. The versatility of packaging tape ensures its usefulness in diverse situations, making it an essential tool for any home or office, surpassing its initial purpose of packaging.

- Q: What are the considerations for using packaging tape on plastic packaging materials?

- When using packaging tape on plastic packaging materials, there are several considerations to keep in mind. First and foremost, the adhesive on the tape should be compatible with the type of plastic being used, as certain plastics may not adhere well to certain types of adhesives. Additionally, the tape should be strong enough to securely hold the packaging together, while also being flexible enough to accommodate any movement or shifting of the materials. It is also important to consider the environmental impact of the packaging tape, opting for eco-friendly options whenever possible. Finally, any printing or labeling on the packaging tape should be legible and easily visible to ensure proper identification and handling of the packaged materials.

- Q: What is the difference between acrylic and hot melt packaging tape?

- Sealing boxes and packages commonly involve the use of acrylic and hot melt packaging tapes, but they differ significantly in their adhesive properties and performance. Acrylic packaging tape boasts clarity and transparency, making it perfect for situations where package appearance matters. It also resists yellowing and aging, ensuring that it remains clear and does not become brittle over time. With a strong initial tack, acrylic tape adheres quickly to surfaces upon application. However, it may not perform as well in extreme temperatures, as its adhesive strength can diminish when exposed to high heat or cold conditions. In contrast, hot melt packaging tape consists of a synthetic rubber adhesive that is applied as a hot liquid. This tape offers superior adhesion and bond strength, making it suitable for heavy-duty or challenging packaging tasks. It excels in temperature resistance, maintaining its adhesive properties even in extreme conditions. Additionally, hot melt tape is known for its quick and effortless release, making it convenient for high-volume packaging operations. In conclusion, acrylic and hot melt packaging tapes are both effective for sealing boxes, but they have distinct advantages and disadvantages. Acrylic tape is ideal for situations prioritizing clarity, aging resistance, and initial tack. On the other hand, hot melt tape excels in adhesion strength, temperature resistance, and ease of use. Ultimately, the choice between the two depends on the specific requirements and conditions of the packaging task at hand.

- Q: Can packaging tape be used for sealing vinyl flooring?

- No, packaging tape is not suitable for sealing vinyl flooring. It is not designed to withstand the wear and tear that flooring endures. It is best to use specific adhesives or tapes recommended for vinyl flooring installation and repair.

Send your message to us

Corporate Packaging Tape - Light Duty Adhesive Masking Tape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 roll

- Supply Capability:

- 30000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords