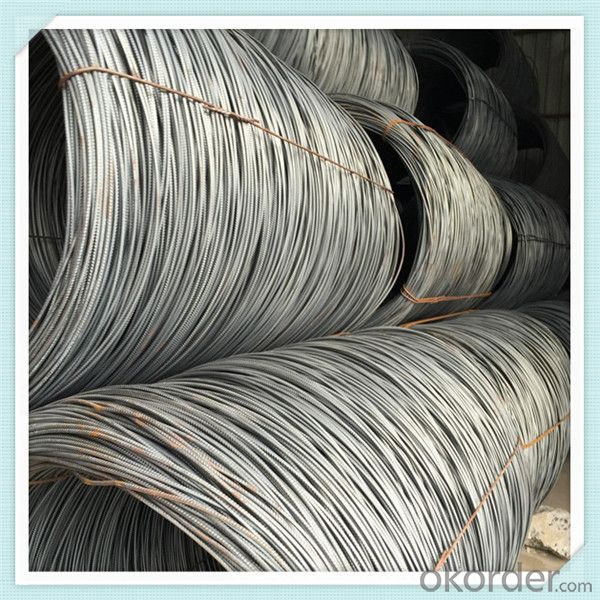

HRB400 steel wire rod hot rolled in good quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 14253 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale,

easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Used to make steel nail, mechanical spare parts. The high carbon steel wire coil is used to make steel

wire rope for different usage, spring steel wire, steel core Al strands, galvanized steel wire, galvanized steel

strands, prestressing steel wire

Mainly used in building and construction as binding wire, tie wire and baling wire; also can be make for wire mesh.

Product Description :

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material/steel grade | Q195-Q235,SAE1006B,SAE1006CR, SAE1008B, SAE1008CR, SAE1010B, SAE1018B, or according to customers requirements |

Wire Gauge | 5.5-12mm |

Coil weight | 1.8-2.1mts |

MOQ | 25MT |

Delivery Time | 15-30 days after receipt of L/C or deposit by T/T |

Packing | In coil and load in container, if large quantity, by bulk vessel; Can be packed as customers' special requirements |

Payment terms | 1).100% irrevocable L/C at sight. 2).30% T/T prepaid and the balance against the copy of B/L. 3).30% T/T prepaid and the balance against L/C |

Application | widely used in machinery parts, manufacturing industry, electronics industry, metal tools and others |

Application :

It generally used in braiding the hose for bathing product and machinery. With it

good flexibility, resistant to high temperature and resistant to corrosion, it

used widely in many industries.

Packing :

Hot-rolled wire rod is held in a unit with at least four steel straps in the

transverse direction and transported and stored without further packaging.

Before

the steel strapping is applied, the wire rod must be sufficiently compressed.

The strapping is fixed in the transverse direction with a single circumferential

strap so that the strapping does not slip and cause the coil to come apart.

Our service:

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing

consistently high standards of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in

customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with

shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can

achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our

key markets. To maintain our position as market leader we must continue to add

value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the

professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3

-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: How is the bending properties of steel wire rod tested?

- Steel wire rod's bending properties are usually assessed using a technique known as the bend test. During this examination, a wire rod sample is manipulated to a specific angle or curvature, and subsequently checked for signs of cracking or breakage. To conduct the test, one end of the wire rod is secured, while force is applied to the other end to facilitate bending. The force required to achieve the desired bend is measured, and the wire rod is visually inspected for indications of deformation or fracture. Additionally, the test may include measuring the wire rod's diameter prior to and after bending, in order to evaluate any alterations in its physical characteristics. By offering valuable insights into the flexibility and ductility of the steel wire rod, the bend test plays a crucial role in determining its suitability for various applications.

- Q: How are steel wire rods used in the manufacturing of mesh screens for sieving materials?

- Steel wire rods are used in the manufacturing of mesh screens for sieving materials by being woven together to create a sturdy and durable mesh structure. The rods are first processed and shaped into thin wires, which are then interwoven or welded together to form a grid-like pattern. This mesh screen allows for the efficient separation of particles based on their size, ensuring that only the desired materials pass through while larger particles are retained. The strength and flexibility of steel wire rods make them ideal for withstanding the rigorous sieving process and maintaining the integrity of the mesh screen.

- Q: What are the common applications of pre-stressed concrete steel wire rod?

- Pre-stressed concrete steel wire rods are commonly used in various construction applications such as bridges, dams, parking structures, and high-rise buildings. They are used to reinforce and strengthen concrete structures, increasing their load-carrying capacity and durability. Additionally, pre-stressed concrete steel wire rods are also utilized in the construction of railway sleepers, poles, and other infrastructure projects.

- Q: What are the trade policies affecting steel wire rod imports and exports?

- The trade policies affecting steel wire rod imports and exports vary from country to country. However, common trade policies include tariffs, quotas, and anti-dumping measures. These policies aim to protect domestic industries, prevent unfair competition, and ensure a level playing field in the global market. Additionally, countries may also negotiate trade agreements and engage in trade disputes to address concerns related to steel wire rod imports and exports.

- Q: What are the different types of coatings for steel wire rod?

- There are several different types of coatings that can be applied to steel wire rods to enhance their performance and protect them from corrosion. Some of the commonly used coatings include: 1. Zinc Coating: Zinc coating, also known as galvanization, is one of the most popular coatings for steel wire rods. It provides excellent corrosion resistance and can be applied through hot-dip galvanizing or electroplating methods. 2. Polymer Coating: Polymer coatings are often used to provide additional protection against corrosion and abrasion. These coatings can be applied by dip coating, extrusion, or powder coating methods, and they offer good adhesion and flexibility. 3. Phosphate Coating: Phosphate coatings are commonly used as a pre-treatment on steel wire rods before applying other coatings. They enhance the adhesion of subsequent coatings and improve corrosion resistance. 4. Epoxy Coating: Epoxy coatings are known for their excellent adhesion and chemical resistance. They are often used in industrial settings where the wire rods are exposed to harsh environments or corrosive substances. 5. Powder Coating: Powder coatings offer a durable and decorative finish to steel wire rods. These coatings are applied as a dry powder and then cured under heat to create a smooth, protective layer. 6. Organic Coating: Organic coatings, such as acrylics or polyurethanes, are often used for aesthetic purposes or to provide a specific color to the wire rods. These coatings also offer some degree of protection against corrosion. 7. Ceramic Coating: Ceramic coatings are used in high-temperature applications where the wire rods are exposed to extreme heat or thermal cycling. These coatings provide excellent heat resistance and can withstand thermal shocks. It's important to choose the appropriate coating based on the specific requirements and intended use of the steel wire rods. Different coatings offer varying levels of protection, durability, and resistance to specific environmental factors.

- Q: How is steel wire rod used in the production of wire mesh for security fencing?

- Steel wire rod is used in the production of wire mesh for security fencing as it serves as the primary raw material. The wire rod is drawn through a series of dies to reduce its diameter, resulting in a thinner and more flexible wire. This wire is then woven or welded together to create the wire mesh, which is then used to construct security fences. The steel wire rod provides strength and durability to the wire mesh, ensuring it can withstand external forces and provide the necessary security.

- Q: What are the different types of steel wire rod finishes for improved chemical resistance?

- There are several types of steel wire rod finishes that can be used to enhance chemical resistance. Some common finishes include galvanized, stainless steel, and epoxy-coated. Galvanized finishes involve coating the steel wire rod with a layer of zinc, which provides protection against corrosion and chemical reactions. Stainless steel finishes are highly resistant to corrosion and are often used in environments with acidic or alkaline substances. Epoxy-coated finishes involve applying a layer of epoxy resin to the steel wire rod, providing a barrier against chemicals and preventing corrosion. Overall, these finishes help improve the chemical resistance of steel wire rods in various applications.

- Q: What are the different shapes of steel wire rod?

- Steel wire rods come in various shapes, including round, square, hexagonal, and rectangular.

- Q: What are the common applications of oil tempered and tempered steel wire rod?

- Oil tempered and tempered steel wire rods have a wide range of applications in various industries. Some of the common applications include: 1. Springs: Oil tempered and tempered steel wire rods are widely used in the manufacturing of springs. The high tensile strength and excellent durability of these wire rods make them ideal for different types of springs, including compression springs, extension springs, and torsion springs. These springs are used in automotive, aerospace, and industrial applications. 2. Wire ropes and cables: Oil tempered and tempered steel wire rods are also used in the production of wire ropes and cables. The high strength and resistance to wear and fatigue of these wire rods make them suitable for applications where heavy loads and high tensile strength are required, such as cranes, elevators, suspension bridges, and mining equipment. 3. Fasteners: Another common application of oil tempered and tempered steel wire rods is in the manufacturing of fasteners, such as bolts, screws, and nails. The strength, toughness, and corrosion resistance of these wire rods ensure the reliability and longevity of fasteners in various construction and industrial applications. 4. Automotive components: Oil tempered and tempered steel wire rods are extensively used in the automotive industry for the production of various components. These wire rods are used in the manufacturing of engine valve springs, clutch springs, suspension springs, and braking systems. The high performance and durability of these wire rods make them suitable for demanding automotive applications. 5. Wire mesh and fencing: Oil tempered and tempered steel wire rods are also utilized in the production of wire mesh and fencing. The strength and resilience of these wire rods make them suitable for creating durable and secure barriers in agricultural, construction, and industrial environments. Overall, oil tempered and tempered steel wire rods have numerous applications due to their high strength, durability, and resistance to wear and fatigue. These wire rods are widely used in springs, wire ropes, fasteners, automotive components, and wire mesh/fencing, contributing to the efficiency and reliability of various industries.

- Q: What are the common industry regulations for steel wire rod?

- The common industry regulations for steel wire rod include specifications for chemical composition, mechanical properties, size tolerances, surface defects, and packaging requirements. These regulations ensure that the steel wire rod meets the required standards for quality and safety in various applications such as construction, manufacturing, and automotive industries.

Send your message to us

HRB400 steel wire rod hot rolled in good quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 14253 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords