HPMC Manufacturers High Viscosity for Building Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of HPMC Manufacturers High Viscosity for Building Materials

HPMC is a non-ionic cellulose ethers produced from matural high molecular cellulose through series of chemical changes, They are characterized by the solubility in water, water retention, non-ionic type, stable pH value, surface activity, reversibility from gelling to solving at different temperature, thickening, binding, film-forming, lubricating and mold resistance. Due to all these special properties, they are widely applied for thickening, gelling, emulsifying, dispersing, stabilizing, water retaining and mixing improving in industries like building material, painting, synthetic resin, porcelain, medicine, food, textile, agriculture, cosmetics and tobacco

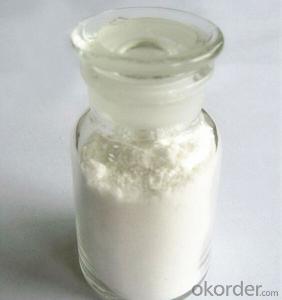

Image of HPMC Manufacturers High Viscosity for Building Materials

Application of HPMC Manufacturers High Viscosity for Building Materials :

HPMC is widely used in food, cosmetic and other daily use chemical lines, Typical usage as following:

1, External wall insulation system (EIFS)

2, Interior and exterior wall interface agent

3, Tile adhesive

4, Crack Filler

5, Self-leveling mortar

6, Gypsum-based plaster

Specification of HPMC Manufacturers High Viscosity for Building Materials

| Item | Specification |

| CAS NO. | 9004-65-3 |

| Appearance | white or light yellow powder |

| Moisture Content | ≤5.0% |

| PH | 4.0-8.0 |

| Particle Size | min. 98% pass through 100 mesh |

| Viscosity | 5000ps-200000cps, 2% solution |

- Q: i‘ve done this experiment on using banana apple and orange peelings cultivated into soil for mustard seeds. we predicted that the banana‘s will produce more flowers than apples and oranges.our hypothesis was correct.what is it about bananas that had a better outcome than the other fruits?

- Banana peels are high in potassium, among other nutrients, that are released when they decompose. These nutrients are taken up by whatever is planted where they decompose. This results in healthier plants and, therefore, healthier blossoms. While apples and oranges are also good soil additives they can't match the nutrients in the banana peels. Good luck and enjoy!

- Q: I have 3 container grow asian pear trees that I want to plant, do I need to add anything to the clay soil to promote a healthy tree?

- There are several good soil additives but I think the experts agree that if you can only add one, use shredded redwood bark.

- Q: Food additive use management system

- the use of units must be used to register. The use of special items must be used by the presence of two or more staff members.

- Q: Apart from flavor enhancers, what other food additives are addictive?

- Tires can cost less than 50 bucks if you get something used and worn, to over 1000 if you get custom colored or have pressure meters. The price you're quoting seems reasonable from a quick search, but without knowing your vehicle, it's hard to say if it's your only choice.

- Q: what are the food additives commonly for use?

- Hey i'm here for the first time. I found this question and I find the answers truly valuable. I'm hoping to give something back and help others too.

- Q: China's first brand of fuel additives which is

- Dimensional chain of oil Po, in 2004 to obtain a patent, has passed the National Petroleum Product Quality Supervision and Inspection Center, the Ministry of Transportation and Transportation Industry Energy Utilization Monitoring Center, the State Environmental Protection Administration of motor vehicle emissions monitoring center, China Petrochemical Petrochemical Research Institute, etc. The authority of the agency's testing, also won the International Invention Exhibition Gold Medal, China Invention Exhibition Gold Award, Fujian Science and Technology Progress Award, Xiamen City Science and Technology Progress Award, the national quality of reliable products, etc., are national and market for vitamin gasoline additives Recognized!

- Q: REAR END OIL CHANGE FOR DODGE RAM 2004 DO WE NEED TO USE A ADDITIVE IF WE USE SYNTHETIC OIL?

- If it is a rear end differential fluid buy yourself a good synthetic differential fluid. Especially if you do any towing. Then no, you will not need to put in an additive unless you are hearing chatter or noise in the differential.

- Q: Food additive red 7 is what red

- The Carmine Carmine, also known as 1- (4'-sulfo-1'-naphthylazo) -2-naphthol-6,8-disulfonic acid trisodium salt, lilac red 4R, CI. Edible red 7 The

- Q: What does it mean by up to isomorphism?

- That notation potential to take g(x) and positioned it in for x interior the f(x) equation. So in f(x) x + a million, i visit throw out the x and put in 2x^2 - 3 {f o g}(x) 2x^2 - 3 +a million Simplify. {f o g}(x) 2x^2 - 2

Send your message to us

HPMC Manufacturers High Viscosity for Building Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords