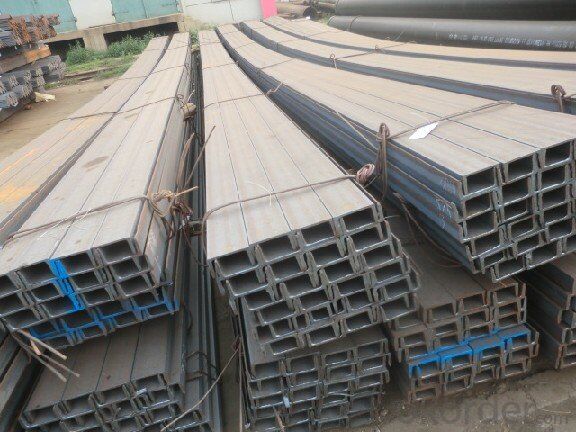

Hot Selling A Grade Quality U Channel Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

high quality Hot Rolled Steel U Beam at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

We supply high quality MS Channel at reasonable price, including Chinese standard, Japanese standard and so on.

Standard | GB/JIS |

Material Grade | Q235,SS400 |

Technique: | Hot Rolled |

Sizes as per chinese standard: | 50*37*4.5mm - 300*89*11.5mm |

Sizes as per japanese standard: | 50*25*3mm – 200*80*7.5mm |

Length: | 6meter, 9meter, 12meter |

Product Applications:

Hot Rolled Steel U-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel U-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

- Q: Can steel channels be used for pedestrian bridges?

- Yes, steel channels can be used for pedestrian bridges. Steel channels are commonly used in bridge construction due to their strength, durability, and versatility. They offer excellent load-bearing capabilities, allowing pedestrians to safely cross the bridge. Steel channels can be designed and fabricated to meet specific bridge requirements, such as span length, weight capacity, and aesthetic considerations. Additionally, steel channels can withstand harsh environmental conditions, making them suitable for outdoor pedestrian bridges that may be exposed to weather elements. Overall, steel channels are a popular choice for pedestrian bridge construction due to their structural integrity and ability to provide a safe and reliable crossing for pedestrians.

- Q: Can steel channels be used for elevator shafts?

- Indeed, it is possible to utilize steel channels in the construction of elevator shafts. Steel channels, characterized by their steel composition and "C" shape, are frequently employed in construction projects for a range of purposes, including elevator shafts. By incorporating steel channels into the design, the elevator shaft structure gains enhanced strength, stability, and support, enabling it to withstand the substantial weight and load of the elevator car, as well as any supplementary loads like individuals or heavy machinery. Moreover, steel channels can be conveniently manufactured and tailored to match the precise specifications of the elevator shaft, rendering them an appropriate selection for this particular application.

- Q: What are the common safety considerations in the design of steel channels?

- When designing steel channels, there are several common safety considerations that need to be taken into account to ensure the overall safety and structural integrity of the channels. These considerations include: 1. Load-bearing capacity: One of the primary safety concerns is ensuring that the steel channels have sufficient load-bearing capacity to support the intended loads. This involves analyzing the expected loads, such as the weight of the materials or equipment that will be placed on the channels, and designing the channels with adequate strength and stiffness to withstand these loads without failure. 2. Material selection: The choice of material for the steel channels is another important safety consideration. The material should have the necessary strength and durability to withstand the anticipated loads, as well as resistance to corrosion, fire, and other potential hazards. The material should also meet the relevant industry standards and specifications. 3. Structural stability: The design of steel channels should ensure their structural stability, which involves considerations such as the proper sizing and positioning of the channels, the use of appropriate connections, and the incorporation of bracing or other reinforcement elements if needed. Structural stability is crucial to prevent buckling, collapse, or other forms of failure under load. 4. Fire resistance: In certain applications, fire resistance is a critical safety consideration for steel channels. Depending on the location and purpose of the channels, they may need to be designed to withstand high temperatures and prevent the spread of fire. This can involve using fire-resistant coatings or insulation materials and designing for proper ventilation to prevent the buildup of heat. 5. Accessibility and ergonomics: Safety considerations also extend to the accessibility and ergonomics of the steel channels, especially in industrial or construction settings. Designers should ensure that the channels are easily accessible for installation, inspection, and maintenance tasks, and that they are designed to minimize potential hazards or risks to workers who may interact with them. 6. Compliance with codes and regulations: Finally, it is essential to consider the relevant codes, standards, and regulations when designing steel channels. Compliance with these requirements ensures that the channels meet the necessary safety standards and are fit for their intended purpose. By addressing these common safety considerations in the design of steel channels, engineers and designers can create structures that are safe, reliable, and able to withstand the intended loads and environmental conditions.

- Q: Are steel channels suitable for mining and industrial applications?

- Yes, steel channels are highly suitable for mining and industrial applications. Steel channels are structural elements made of steel that possess excellent strength and durability, making them ideal for heavy-duty applications. In mining, steel channels are commonly used for the construction of support structures such as roof supports, beams, and columns. They provide the necessary strength to withstand the extreme conditions, loads, and vibrations associated with mining operations. In industrial applications, steel channels are widely utilized for various purposes. They are commonly used as support structures for heavy machinery and equipment, providing stability and rigidity. Steel channels also serve as frames for conveyor systems, platforms, and walkways, ensuring safe and efficient movement within industrial facilities. Their versatility allows them to be customized and adapted to specific requirements, making them an excellent choice for different industrial applications. Furthermore, steel channels offer several advantages that make them suitable for mining and industrial applications. Firstly, steel is highly resistant to corrosion, which is crucial in environments where exposure to moisture, chemicals, and other harsh elements is common. This resistance ensures the longevity and reliability of the steel channels, reducing maintenance costs. Secondly, steel channels have excellent load-bearing capacity, allowing them to bear heavy loads and withstand significant forces. This is essential in mining and industrial settings, where heavy machinery, equipment, and materials are often involved. Lastly, steel channels can be easily fabricated and installed, providing flexibility in design and construction. They are available in various sizes, shapes, and lengths, allowing them to be tailored to specific project requirements. Their ease of installation also minimizes downtime during construction, ensuring efficient operations in mining and industrial applications. In conclusion, steel channels are highly suitable for mining and industrial applications due to their strength, durability, corrosion resistance, load-bearing capacity, and ease of fabrication and installation. They provide the necessary support and stability required in these demanding environments, making them a reliable choice for such applications.

- Q: How do steel channels perform in corrosive chemical environments?

- Steel channels generally perform well in corrosive chemical environments due to their high resistance to corrosion. This is primarily because steel, especially stainless steel, forms a protective oxide layer that prevents or slows down the corrosion process. However, the exact performance can vary depending on the specific chemical environment and concentration. It is important to consider the corrosive properties of the chemicals and consult with experts or engineers to select the appropriate type and grade of steel channel for optimal performance and longevity in corrosive chemical environments.

- Q: What material is the channel steel bought in the steel market?

- Carbon structural steels are normally used directly under heat supply without heat treatment.

- Q: Can steel channels be used for exhibition stands?

- Yes, steel channels can be used for exhibition stands. Steel channels are commonly used in construction and engineering industries for their strength and durability. They provide excellent structural support, making them ideal for creating sturdy exhibition stands. Additionally, steel channels can be easily customized and shaped to fit specific design requirements, allowing for versatile and unique stand designs.

- Q: How do steel channels perform under live loads?

- Steel channels are highly durable and reliable structural components that are commonly used in construction projects. When it comes to their performance under live loads, steel channels exhibit excellent load-bearing capabilities. They have the ability to support heavy loads and distribute them evenly along their length, making them suitable for applications where live loads, such as people or equipment, are present. The design of steel channels allows them to efficiently resist bending and buckling, ensuring the integrity and stability of the structure. The shape and cross-section of steel channels provide a high moment of inertia, which contributes to their superior load-carrying capacity. This means that they can withstand larger live loads without experiencing excessive deflection or deformation. Additionally, steel channels offer high strength-to-weight ratio, making them an ideal choice for structures that require considerable load-bearing capacity while keeping the weight of the structure at a minimum. This advantage makes steel channels particularly suitable for applications where the weight of the structure needs to be minimized, such as in bridges or overhead cranes. Moreover, steel channels are highly resistant to fatigue, which means that they can withstand repeated loading and unloading without experiencing any significant loss in performance. This characteristic makes them well-suited for applications that involve dynamic loads, such as moving vehicles or heavy machinery. In summary, steel channels perform exceptionally well under live loads. They have the ability to support heavy loads, distribute them evenly, resist bending and buckling, and withstand repeated loading. These qualities make steel channels a reliable and efficient choice for various construction projects that require superior load-bearing capacity and structural stability.

- Q: Do steel channels have any specific thermal expansion properties?

- Yes, steel channels do have specific thermal expansion properties. Like all materials, steel expands and contracts with changes in temperature. The thermal expansion of steel channels is primarily determined by the coefficient of linear expansion, which is a measure of how much the material expands per unit length per degree Celsius (or per unit length per degree Fahrenheit). The coefficient of linear expansion for steel typically ranges between 10 to 13 parts per million per degree Celsius (10-13 ppm/°C). This means that for every degree Celsius increase in temperature, a steel channel will expand by approximately 10 to 13 parts in a million of its original length. It is important to consider the thermal expansion of steel channels in various applications to ensure proper design and functionality. For example, in structures where steel channels are used, such as bridges or buildings, allowance must be made for the expansion and contraction of the channels to prevent stress buildup and potential damage. Expansion joints or other methods of accommodating thermal expansion are typically incorporated into the design to account for these properties. In summary, steel channels do exhibit specific thermal expansion properties, which are determined by the coefficient of linear expansion. Understanding and accounting for these properties is crucial in the design and application of steel channels to ensure their structural integrity and functionality in varying temperature conditions.

- Q: How do steel channels contribute to building security?

- Steel channels contribute to building security by providing structural support and reinforcement. They are commonly used in the construction of walls, floors, and roofs to enhance the overall strength and stability of the building. Steel channels help distribute the weight and loads evenly, making the structure more resistant to external forces such as strong winds, earthquakes, or impact. Additionally, they can be integrated with security systems to serve as barriers, preventing unauthorized access and enhancing the physical security of the building.

Send your message to us

Hot Selling A Grade Quality U Channel Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords