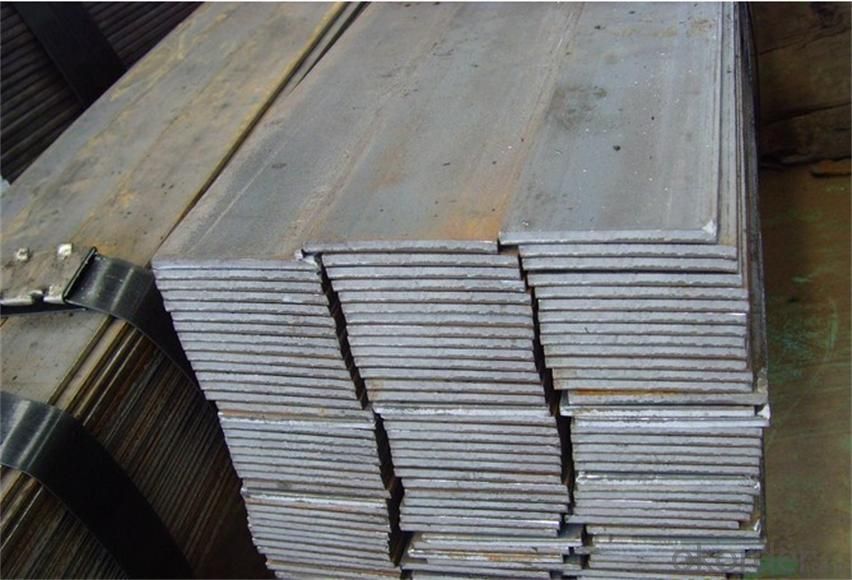

Hot rolled steel flat bar in Grade Q235 for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering hot rolled steel flat bar in Grade Q235 for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot rolled steel flat bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Flat Bar for construction are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Chinese Standard (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light I (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light II (H*W*T) | Weight (Kg/m) | 6M |

100*68*4.5 | 11.261 | 14.8 | 100*66*4.3 | 10.13 | 16.4 | 100*64*4 | 8.45 | 19.7 |

120*74*5.0 | 13.987 | 11.9 | 120*72*4.8 | 12.59 | 13.2 | 120*70*4.5 | 10.49 | 15.8 |

140*80*5.5 | 16.89 | 9.8 | 140*78*5.3 | 15.2 | 10.9 | 140*76*5 | 12.67 | 13.1 |

160*88*6 | 20.513 | 8.1 | 160*86*5.8 | 18.46 | 9 | 160*84*5.5 | 15.38 | 10.8 |

180*94*6.5 | 24.143 | 6.9 | 180*92*6.3 | 21.73 | 7.6 | 180*90*6 | 18.11 | 9.2 |

200*100*7 | 27.929 | 5.9 | 200*98*6.8 | 25.14 | 6.6 | 200*96*6.5 | 20.95 | 7.9 |

220*110*7.5 | 33.07 | 5 | 220*108*7.3 | 29.76 | 5.6 | 220*106*7 | 24.8 | 6.7 |

250*116*8 | 38.105 | 4.3 | 250*114*7.8 | 34.29 | 4.8 | 250*112*7.5 | 28.58 | 5.8 |

280*122*8.5 | 43.492 | 3.8 | 280*120*8.2 | 39.14 | 4.2 | 280*120*8 | 36.97 | 4.5 |

300*126*9 | 48.084 | 3.4 | 300*124*9.2 | 43.28 | 3.8 | 300*124*8.5 | 40.87 | 4 |

320*130*9.5 | 52.717 | 3.1 | 320*127*9.2 | 48.5 | 3.4 | |||

360*136*10 | 60.037 | 2.7 | 360*132*9.5 | 55.23 | 3 |

FAQ

Q1: What makes stainless steel stainless?

A1: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q2: Can stainless steel rust?

A2: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: What is the typical price range for steel flat bars?

- The typical price range for steel flat bars can vary depending on factors such as size, thickness, and the current market conditions. However, as a general guideline, the price range for steel flat bars can range from around $10 to $50 per foot.

- Q: What are the safety precautions when working with steel flat bars?

- When working with steel flat bars, it is important to follow certain safety precautions to prevent injuries and ensure a safe working environment. Here are some key safety precautions to consider: 1. Personal Protective Equipment (PPE): Always wear the necessary PPE, such as safety goggles, gloves, steel-toed boots, and a hard hat. These items will protect you from potential hazards like flying debris, sharp edges, and falling objects. 2. Proper Lifting Techniques: Steel flat bars can be heavy, so use proper lifting techniques to avoid strain or injury. Bend your knees, keep your back straight, and use your leg muscles to lift the bars. If the bars are too heavy, ask for assistance or use lifting equipment. 3. Secure Work Area: Ensure your work area is organized, clean, and free from any obstacles. This will minimize the risk of tripping or falling while handling steel flat bars. Also, make sure the floor is dry to prevent slips and falls. 4. Sharp Edges: Steel flat bars often have sharp edges that can cause cuts or punctures. Be cautious when handling them, and use appropriate tools to avoid direct contact with the sharp edges. If necessary, wear protective gloves or wrap the sharp edges with duct tape or rubber to prevent injuries. 5. Machinery and Tools: When using machinery or tools, always follow the manufacturer's instructions and safety guidelines. Ensure that the equipment is in good working condition, properly maintained, and appropriate for the task at hand. Use guards and safety features provided by the equipment whenever possible. 6. Fire Safety: Steel flat bars are highly flammable when exposed to extreme heat or sparks. Therefore, it is crucial to have fire extinguishers readily available and to follow proper fire safety protocols in your work area. 7. Training and Knowledge: Ensure that you have received proper training on how to handle and work with steel flat bars. Familiarize yourself with the material's properties, potential hazards, and safe working practices. If you are unsure about any aspect, consult with a knowledgeable supervisor or expert. 8. Communication and Teamwork: If working as part of a team, communicate with your coworkers to ensure everyone is aware of the tasks being performed and any potential risks involved. Maintain clear and effective communication to avoid accidents and promote a safe working environment. By following these safety precautions, you can minimize the risks associated with working with steel flat bars and create a safer and more productive work environment.

- Q: Are steel flat bars available in different surface finishes?

- Yes, steel flat bars are available in different surface finishes. Some common surface finishes for steel flat bars include mill finish, hot rolled, cold rolled, brushed, polished, and galvanized. Each surface finish has its own unique characteristics and is suitable for different applications. For example, mill finish is the basic surface finish that is achieved after the steel is manufactured, while hot rolled has a rougher texture and is commonly used for structural applications. Cold rolled steel flat bars have a smoother surface finish and are often used in decorative applications. Brushed and polished finishes provide a more refined and aesthetically pleasing appearance. Galvanized steel flat bars have a protective zinc coating that helps prevent corrosion. Overall, the availability of different surface finishes allows steel flat bars to be used in a wide range of applications while meeting specific requirements for appearance and functionality.

- Q: How do steel flat bars perform under impact or shock-loading conditions?

- Steel flat bars generally perform well under impact or shock-loading conditions due to their high strength and resilience. The toughness and ductility of steel allow it to absorb and distribute the energy generated during impact, reducing the risk of deformation or fracture. Additionally, steel's ability to withstand high forces and maintain its structural integrity makes it a reliable choice for applications requiring resistance to impact or shock-loading.

- Q: Can steel flat bars be used for manufacturing agricultural equipment or machinery?

- Yes, steel flat bars can be used for manufacturing agricultural equipment or machinery. Steel is a strong and durable material that can withstand the heavy loads and harsh conditions often encountered in agricultural settings. Steel flat bars can be shaped, welded, and formed into various components required for agricultural equipment such as plows, cultivators, trailers, and machinery parts. The versatility of steel allows for customization and adaptation to different agricultural applications, making it a reliable choice for manufacturing agricultural equipment and machinery.

- Q: What are the load capacities of steel flat bars?

- The load capacities of steel flat bars vary depending on their dimensions and the specific grade of steel used. However, steel flat bars are known for their high strength and load-bearing capacity, making them suitable for various applications such as construction, manufacturing, and structural support. It is important to consult engineering specifications and calculations to determine the precise load capacities for a specific steel flat bar.

- Q: Can steel flat bars be used for reinforcing concrete?

- Indeed, reinforcing concrete with steel flat bars is feasible. Concrete structures frequently incorporate steel flat bars as a means to augment their resilience and endurance. These bars are typically inserted either horizontally or vertically into the concrete, thereby furnishing supplementary tensile strength and averting cracks or structural collapse. By utilizing steel flat bars as reinforcement, the load is more evenly dispersed, thereby ameliorating the concrete's overall functionality. Moreover, the steel bars foster resistance against bending and shear forces, thereby further fortifying the concrete's structural integrity.

- Q: How do steel flat bars perform in terms of chemical resistance?

- Steel flat bars generally have good chemical resistance. However, the level of resistance can vary depending on the specific grade and composition of the steel. Stainless steel flat bars, for example, have excellent resistance to a wide range of chemicals, including acids, alkalis, and organic solvents. This is due to the high chromium content in stainless steel, which forms a protective oxide layer on the surface, known as passive film, that prevents corrosion and chemical attack. On the other hand, carbon steel flat bars, while more susceptible to corrosion, still exhibit decent chemical resistance in many environments. They are resistant to most organic chemicals, but can be affected by strong acids, alkalis, and certain corrosive agents. In such cases, protective coatings or surface treatments can be applied to enhance the chemical resistance of carbon steel. Overall, steel flat bars are commonly used in various industries due to their good chemical resistance. However, it is important to consider the specific grade and composition of the steel, as well as the intended application and the specific chemicals it will be exposed to, in order to determine the level of chemical resistance required.

- Q: What are the different methods of surface protection for steel flat bars in corrosive environments?

- There are several methods of surface protection for steel flat bars in corrosive environments. Some of the commonly used methods include: 1. Galvanization: This process involves coating the steel flat bars with a layer of zinc. The zinc acts as a sacrificial anode, protecting the steel from corrosion. Galvanization can be done through hot-dip galvanizing, where the bars are immersed in a bath of molten zinc, or through electroplating, which involves the application of zinc using an electric current. 2. Powder coating: Powder coating involves applying a dry powder onto the surface of the steel flat bars. The powder is then heated and cured, forming a protective layer. Powder coating provides excellent corrosion resistance and can be customized in terms of color and finish. 3. Paint or epoxy coating: Applying a layer of paint or epoxy coating can effectively protect steel flat bars from corrosion. These coatings act as a barrier between the metal and the corrosive environment, preventing moisture and chemicals from reaching the surface of the steel. 4. Stainless steel cladding: In this method, a layer of stainless steel is bonded to the surface of the steel flat bars. Stainless steel is highly resistant to corrosion, making it an effective protective layer against corrosive environments. 5. Organic coatings: Organic coatings, such as polyurethane or acrylic coatings, can be applied to steel flat bars to provide corrosion protection. These coatings create a barrier that prevents moisture and corrosive agents from reaching the steel surface. 6. Metal plating: Steel flat bars can be plated with metals such as nickel or chrome to enhance their corrosion resistance. The plating process involves immersing the bars in a solution containing the metal ions, which then adhere to the surface of the steel. It is important to consider the specific requirements of the corrosive environment and the expected lifespan of the steel flat bars when selecting a surface protection method. Each method has its own advantages and limitations, so choosing the most suitable option will depend on factors such as cost, durability, and the severity of the corrosive environment.

Send your message to us

Hot rolled steel flat bar in Grade Q235 for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords