Hot Rolled JIS U-channel Carbon Steel HIgh Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering STEEL CHANNEL at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

1.The JIS channel can be devided into two kinds, namely common channel steel and light channel steel. The sizes of hot rolled common channel steel range from 5# to 40#. Meanwhile, the channel steel can be divided into cold forming sectional equal channel steel, cold forming sectional unequal channel steel, cold forming inner edge channel steel and outer edge channel steel.

2.The JIS channel is usually used for arch-itechtural structure, and they could be welded in order to support or hang a vari-ety of facilities. They are also usually used in combination with I beam. The channel steel with sizes under 14# is usually applied to construction engineering, as purline, while the channel steel with sizes above 16# is more likely to be used in building vehicle chassis structure and mechanical structure. Furthermore, the channel steel in sizes above 30# are target at building bridge structure, as tension bar.

3.In a word, the channel steel must possess perfect welding property, riveting property and mechanical property and so on.

Product Advantages:

OKorder's STEEL CHANNELare durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Minimum Order Quantity: 25 Tons Unit: m.t. Loading Port: Xingang Port

Supply Ability: 1000 Tons Per Day Payment Terms: TT or L/C

Product Description:

Specifications of Steel U Channel:

Standard Applied: GB Standard, EN Standard(UPN), JIS Standard

Sizes: 50mm to 300mm

Material Grade: Q235B, Q345B, S235JR, SS400, ASTM A36

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 | B | 0.12-0.20 | 0.3-0.7 | ≦0.045 | ≦0.045 | ≦0.3 |

Alloy No | Grade | Yielding Strength Point(Mpa) | |||

Thickness(mm) | |||||

≦16 | >16-40 | >40-60 | >60-100 | ||

≧ | |||||

Q235 | B | 235 | 225 | 215 | 205 |

Table-3-1

Alloy No | Grade | Tensile Strength(Mpa) | Elongation After Fracture(%) | |||

Thickness(mm) | ||||||

≦16 | >16-40 | >40-60 | >60-100 | |||

≧ | ||||||

G235 | B | 375-500 | 26 | 25 | 24 | 23 |

Production Flow of JIS Channel:

1.The steel billet shall be heated in the high temperature furnace.

2. The heated steel billet shall be rolled five to nine times with the aim of shaping the general figure of steel u channel.

3. The rolled steel channel should be put onto the cooling bed to make the temperature low.

4. The JIS Channel should be straighted on the straightener.

5. The straighted steel u channel will be cut into meters by saw, as per customer's requirements.

6. At the last part of production, the channel steel must be tested in order to confirm that the finished products are completely free from crack, pore, slag, scab or fold on the surface.

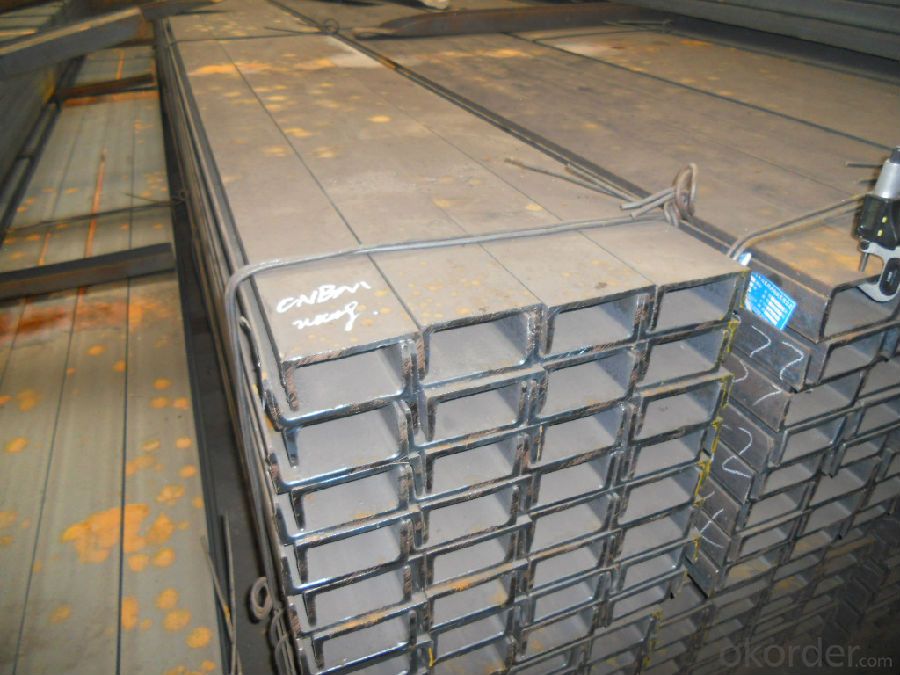

Package & Delivery: Steel U Channel

The steel u channel will be packed in bundle with steel wire at each end of every bundle and color marking in order to help the customer to recognize his goods more easily at sight.

And steel u channel could be loaded into 20ft or 40ft container, or by bulk cargo. If the weight of each bundle reaches less than 3.5 mt, the loading by break bulk cargo should be choosed. When the weight of each bundle reaches less than 3mt, the loading by container should be choosed.

As for the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

All in all, we could do in accordance with customer's request

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Images:

- Q: Can steel channels be used in telecommunications infrastructure?

- Yes, steel channels can be used in telecommunications infrastructure. Steel channels are commonly used in the construction of electrical and telecommunications towers, as well as in the installation of various equipment such as antennas, cables, and support structures. The strength and durability of steel make it an ideal material for supporting heavy equipment and ensuring the stability and longevity of telecommunications infrastructure. Additionally, steel channels can be easily customized and fabricated to meet specific requirements, allowing for efficient installation and maintenance processes.

- Q: What are the weight-bearing capacities of steel channels?

- The weight-bearing capacities of steel channels vary depending on several factors including the dimensions and design of the channel, the grade of steel used, and the specific loading conditions. Steel channels are commonly used in construction and structural applications for their strength and durability. To determine the weight-bearing capacity of a steel channel, engineers typically calculate the maximum load it can support without experiencing failure or deformation. This calculation is based on various mechanical properties of the steel, such as its yield strength, ultimate tensile strength, and section modulus. Yield strength refers to the maximum stress a material can withstand without permanent deformation, while ultimate tensile strength indicates the maximum stress it can handle before breaking. Section modulus, on the other hand, measures the resistance of a cross-sectional shape to bending and is essential for determining the load-carrying capacity of a steel channel. To obtain specific weight-bearing capacities, it is necessary to consult engineering design tables, manufacturer specifications, or consult with a structural engineer. These resources provide detailed information on the weight-bearing capacities of different steel channel sizes and shapes based on their design, material properties, and intended usage. In conclusion, the weight-bearing capacities of steel channels depend on various factors and can only be accurately determined through engineering calculations, referencing design tables, or consulting with professionals in the field of structural engineering.

- Q: Are steel channels suitable for high-rise construction?

- High-rise construction finds steel channels to be a suitable option. These channels, composed of steel with a C-shaped cross-section, serve as structural components. Their strength, durability, and versatility make them commonly used in construction. In the realm of high-rise construction, where buildings face substantial vertical and lateral loads, steel channels offer multiple advantages. Firstly, they possess a high load-bearing capacity, enabling them to bear the weight of the building and endure the forces exerted upon it. This characteristic proves crucial in high-rise construction, where structural components must withstand significant loads, including the weight of multiple floors, occupants, and equipment. Secondly, steel channels demonstrate exceptional durability and resilience, allowing them to withstand harsh weather conditions, seismic activities, and other external factors. This aspect holds particular importance for high-rise buildings, as they face more extreme conditions compared to low-rise structures. Steel channels provide the necessary strength and resilience to maintain the structural integrity of the building throughout its lifespan. Additionally, steel channels exhibit versatility, as they can be readily fabricated, customized, and installed in various configurations to meet the specific requirements of high-rise construction. They can function as primary structural elements or as secondary components to support other structural members. Their flexibility facilitates efficient design and construction, empowering architects and engineers to create tall and intricate structures. Moreover, steel channels offer cost-effectiveness in high-rise construction. Steel is a relatively affordable and easily accessible material, making it an economical choice for large-scale projects. Furthermore, steel channels can be prefabricated off-site, reducing construction time and labor costs. Overall, steel channels prove well-suited for high-rise construction due to their strength, durability, versatility, and cost-effectiveness. They provide the necessary structural support and resilience required for tall buildings, establishing themselves as a dependable choice for this type of construction.

- Q: Calculated weight of channel steel

- Channel theory, weight calculation, steel theory, weight measurement units of kg (kg).

- Q: Can steel channels be used for fencing applications?

- Yes, steel channels can be used for fencing applications. Steel channels provide strength, durability, and stability, making them suitable for fencing purposes. They are commonly used as posts or horizontal supports in fencing systems, providing a robust framework for the fence panels.

- Q: Are steel channels suitable for coastal applications?

- Indeed, steel channels prove to be a fitting choice for coastal applications. Given their resilience and ability to resist corrosion, steel channels are widely utilized in coastal regions. The coastal environment presents distinct challenges, including elevated moisture levels, exposure to saltwater, and formidable winds, all of which hasten material decay. Nevertheless, steel channels are purposefully designed to withstand these conditions. Typically crafted from stainless steel or galvanized steel, they possess a protective layer that deters rust and corrosion. Additionally, steel channels boast exceptional strength and structural integrity, rendering them an apt choice for coastal applications such as seawalls, docks, piers, and various other marine infrastructure projects.

- Q: Could you tell me the theoretical weight and size of 16 and 18 channel steel?

- 14 # A 140×58×6.0 14.53514 # 140×60×8.0 16.733 B16 # a 160×63×6.5 17.2416 # B 160×65×8.5 19.75218 # a 180×68×7.0 20.174# 180×70×18 B 9 2320 # a 200×73×7.0 22.63720 # B 200×75×9.0 25.777

- Q: Are steel channels suitable for marine applications?

- Steel channels are highly suitable for marine applications due to their strength and durability. They are crafted from a resilient material that is resistant to corrosion, making them an ideal choice for marine settings where saltwater exposure is constant. These channels are capable of enduring the harsh conditions of the ocean, including high levels of moisture, waves, and wind. Furthermore, they possess exceptional structural integrity and can provide support and stability for various marine structures like piers, docks, and offshore platforms. In addition to this, they are commonly employed in shipbuilding and the construction of marine vessels. All in all, steel channels offer a reliable and practical solution for marine applications as they possess the necessary strength, corrosion resistance, and ability to withstand the demanding conditions of the marine environment.

- Q: How do steel channels contribute to building security?

- Steel channels can contribute significantly to building security due to their inherent strength and durability. They are commonly used in construction to provide structural support and reinforcement, particularly in areas where additional strength is required. One of the main benefits of steel channels is their ability to resist impact and withstand extreme forces. This makes them highly resistant to forced entry, such as ramming or cutting attempts. Their robustness acts as a deterrent to potential intruders, as the level of effort and time required to breach a building with steel channels is significantly higher compared to structures with weaker materials. Moreover, steel channels are often utilized in the construction of doors, windows, and other entry points. By incorporating steel channels into these vulnerable areas, building security is enhanced. These channels reinforce the frames, making them more resistant to break-ins and forced openings. Additionally, steel channels can be utilized to create secure barriers within a building, such as partitions or security gates. These barriers can be placed strategically to control access and movement, particularly in high-security areas. Steel channels can be integrated with other security features, such as locking mechanisms and access control systems, to further enhance building security. Furthermore, steel channels have excellent fire resistance properties. In the event of a fire, steel channels can help maintain the structural integrity of a building, preventing collapse and allowing occupants to evacuate safely. This is crucial for building security, as it ensures the safety of individuals inside and minimizes the risk of injury or loss of life. In conclusion, steel channels contribute to building security by providing strength, durability, and resistance to forced entry. They can reinforce doors, windows, and other vulnerable areas, acting as a physical barrier against intrusion. Steel channels can also create secure barriers within a building and enhance fire resistance, further enhancing overall building security.

- Q: Can steel channels be used in the construction of railings or handrails?

- Yes, steel channels can be used in the construction of railings or handrails. Steel channels are often chosen for their strength and durability, making them a suitable material for supporting and securing railings or handrails. They can be easily fabricated and installed, providing a sturdy structure that can withstand heavy loads and ensure the safety of individuals using the railing or handrail. Additionally, steel channels can be designed in various shapes and sizes, allowing for flexibility in creating different railing or handrail designs to suit specific architectural requirements.

Send your message to us

Hot Rolled JIS U-channel Carbon Steel HIgh Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords