Hot Rolled Channel Steel 2015 Hot Sell JIS Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

2015 Hot Sell JIS Hot Rolled Channel Steel Details

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Dimensions: | 50*37*4.5mm -400*104*14.5mm | Grade: | Q235 |

Place of Origin: | Hebei China (Mainland) | Brand Name: | jinding | Model Number: | 50*37*4.5mm -400*104*14.5mm |

Shape: | U Channel | Application: | construction | Perforated Or Not: | Is Perforated |

hot rolled: | channel steel | economic price: | channel steel | LC payment: | channel steel |

Packaging & Delivery

Packaging Detail: | Tied And Band With 6mm Wire Rod in Four Places Tightly |

Delivery Detail: | within 20 Days |

2015 Hot Sell JIS Hot Rolled Channel Steel Specifications

1.channel steel: ss400/q235/st37-2/a36/s235jr

2.channel steel 5.8/6/9/12m

3.LC payment channel steel

4.delivery within 25 day

Chinese standard size: 50*37*4.5mm -400*104*14.5mm

Japanese standard size: 50*25*3mm-300*90*13mm

| Size (mm) | Thickness (mm) | Thickness (mm) | Weight (kg/m) |

| 50*25 | 3.00~5.00 | 6.00 | 2.37~3.46 |

| 75*40 | 3.80 | 7.00 | 5.30 |

| 75*40 | 4.00 | 7.00 | 5.60 |

| 75*40 | 4.50 | 7.00 | 5.85 |

| 75*40 | 5.00 | 7.00 | 6.92 |

| 100*50 | 3.80 | 6.00 | 7.30 |

| 100*50 | 4.20 | 6.00 | 8.03 |

| 100*50 | 4.50 | 7.50 | 8.97 |

| 100*50 | 5.00 | 7.50 | 9.36 |

| 125*65 | 5.20 | 6.80 | 11.66 |

| 125*65 | 5.30 | 6.80 | 12.17 |

| 125*65 | 5.50 | 8.00 | 12.91 |

| 125*65 | 6.00 | 8.00 | 13.40 |

| 150*75 | 5.50 | 7.30 | 14.66 |

| 150*75 | 5.70 | 10.00 | 16.71 |

| 150*75 | 6.00 | 10.00 | 17.90 |

| 150*75 | 6.50 | 10.00 | 18.60 |

| 150*75 | 9.00 | 12.50 | 24.00 |

| 200*80 | 7.50 | 11.00 | 24.60 |

| 200*90 | 8.00 | 13.50 | 30.30 |

| 250*90 | 9.00 | 13.00 | 34.60 |

| 300*90 | 9.00 | 13.00 | 38.10 |

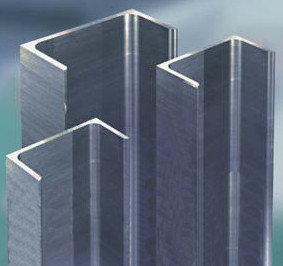

2015 Hot Sell JIS Hot Rolled Channel Steel Pictures

- Q: Can steel channels be used in the aerospace parts manufacturing industry?

- Yes, steel channels can be used in the aerospace parts manufacturing industry. Steel channels are often used in the aerospace industry for various applications such as structural components, support frames, and load-bearing structures. They provide high strength, durability, and excellent structural integrity, making them suitable for aerospace applications where strength and reliability are crucial.

- Q: Can steel channels be used in the agricultural manufacturing industry?

- Yes, steel channels can be used in the agricultural manufacturing industry. Steel channels are versatile and durable, making them suitable for various applications in agriculture, such as constructing farm equipment, machinery, and structures like barns and sheds.

- Q: What about channel 16?

- Channel steel is a kind of carbon structural steel used for construction and machinery. It is a complex section steel. Its cross section has a groove shape. Channel steel is mainly used in building structure, curtain wall engineering, mechanical equipment and vehicle manufacturing, etc.. In use, it requires better welding, riveting performance and comprehensive mechanical properties. The raw material steel billet for channel steel is carbon or low alloy steel billets with a carbon content of not more than 0.25%. The finished channel steel is delivered by hot forming, normalizing or hot rolling.

- Q: Can steel channels be used in telecommunications towers?

- Yes, steel channels can be used in telecommunications towers. Steel channels have a range of applications due to their strength, durability, and versatility. In telecommunications towers, steel channels can be used for structural support, providing stability and load-bearing capacity for the tower. The channels can be fabricated and assembled to form the framework of the tower, allowing for the installation of various equipment such as antennas, transmitters, and receivers. Additionally, the design of steel channels allows for easy integration of cables and wiring, facilitating efficient connectivity throughout the tower. Overall, the use of steel channels in telecommunications towers ensures a sturdy and reliable infrastructure for efficient and effective communication networks.

- Q: How do steel channels contribute to sound insulation?

- Steel channels can contribute to sound insulation by providing a rigid structure that helps to minimize the transmission of sound waves. When steel channels are used in the construction of walls or ceilings, they create a framework that can be filled with sound-absorbing materials such as insulation or acoustic panels. This combination of the steel channels and sound-absorbing materials helps to dampen and absorb sound energy, reducing the amount of noise that can pass through the structure. Additionally, steel channels can also be used to create double or staggered wall systems, which further enhances sound insulation by creating air gaps that act as barriers to sound transmission. Overall, steel channels play a crucial role in sound insulation by providing a solid foundation and structure for sound-absorbing materials and creating a barrier that prevents sound from traveling through the building.

- Q: What are the specifications for steel channels?

- Steel channels have specific specifications in terms of their dimensions, material composition, and mechanical properties. The specifications for steel channels may vary depending on the industry standards and requirements. Firstly, the dimensions of steel channels are important specifications to consider. These dimensions include the height, width, and thickness of the channel. Steel channels are typically available in a range of sizes, with standard sizes such as C3x4.1 or C6x10.5, where the first number denotes the channel height and the second number represents the weight per linear foot. Additionally, the material composition of steel channels is a crucial specification. Steel channels are made from various types of steel, including carbon steel, alloy steel, or stainless steel. The specific steel grade used will depend on the intended application and the desired strength and corrosion resistance properties. Moreover, steel channels also have mechanical properties that should be specified. These properties include the yield strength, tensile strength, and elongation of the steel. These mechanical properties determine the load-bearing capacity and durability of the steel channel. Different applications may require steel channels with specific mechanical properties to ensure structural integrity and safety. Furthermore, the surface finish and coating specifications for steel channels may also be important. Steel channels can be supplied with different surface finishes, such as hot-rolled, cold-rolled, or galvanized finishes. Coatings like zinc or paint can be applied to enhance corrosion resistance and aesthetics. In summary, the specifications for steel channels encompass dimensions, material composition, mechanical properties, surface finish, and coating. These specifications are essential to ensure the proper selection and use of steel channels in various applications such as construction, manufacturing, and infrastructure projects.

- Q: What are the different methods for joining multiple steel channels together?

- There are several methods for joining multiple steel channels together, including welding, bolting, riveting, and using adhesive or epoxy.

- Q: Can steel channels be used for playground equipment?

- Indeed, playground equipment can utilize steel channels. The construction industry frequently employs steel channels due to their robustness and resilience, rendering them appropriate for playground equipment. They offer a firm and secure framework capable of bearing the weight of children and enduring the constant usage. Furthermore, steel channels can be effortlessly molded and welded to form diverse structures and designs for playground equipment, including slides, climbing frames, and swing sets. Their adaptability and capacity to withstand harsh weather conditions make them a perfect choice for long-lasting and child-safe playground equipment.

- Q: How do steel channels contribute to the overall sustainability of a construction project?

- Steel channels contribute to the overall sustainability of a construction project by providing strength and durability to the structure. As steel channels can be recycled and reused, they help reduce the demand for new materials and minimize waste. Additionally, their long lifespan and resistance to corrosion reduce the need for frequent replacements, making them a sustainable choice for construction projects.

- Q: Can steel channels be used for roof structures?

- Yes, steel channels can be used for roof structures. Steel channels are strong and durable, making them suitable for supporting the weight of a roof. They can provide structural stability and support, making them a popular choice in construction for various types of roofs.

Send your message to us

Hot Rolled Channel Steel 2015 Hot Sell JIS Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords