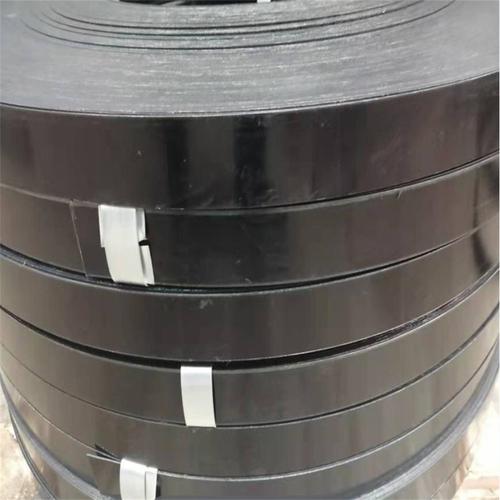

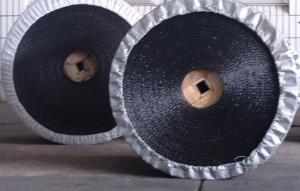

High strength straight disc painted packing tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 2500 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

High strength straight disc painted packing tape

Painted packing tape is an important material widely used in logistics, packaging, construction and other fields.

Painted strapping has the following advantages:

1. It has good tensile resistance and is not easy to break;

2. It has good corrosion resistance and wear resistance, and can be used for a long time;

3. It has good insulation performance and can protect packaging items from static electricity and electromagnetic interference;

4. It has good environmental performance and can be recycled and reused.

Process: Hot rolled coil - acid pickling - cold rolling - slitting - annealing - dipping - air drying - coiling - finished product packaging

According to strength, it can be divided into low strength (550-650Mpa), medium strength (650-750Mpa), high strength (750-850Mpa), and ultra-high strength (850-950Mpa)

Technical requirements: The surface is allowed to have individual concave surfaces, protrusions, longitudinal scratches, and abrasions greater than half of the allowable thickness tolerance, but there must be no rust, and the edges must not have burrs, edges, or uneven cutting.

Usage: Painted strapping tape is mainly suitable for packaging and bundling steel plates, steel coils, steel pipes, aluminum ingots, zinc ingots, light textiles, wooden products, and other steel strips.

- Q: Production process of PP packing belt

- Easy to stretch orientation to obtain high quality products. Then, the tensile and tensile purposes are to increase the longitudinal strength of the strap and reduce the elongation.

- Q: How is the packing belt sold?

- The packing belt is usually sold by the kilo, and some will be sold by volume, as per the guest's custom.

- Q: What's the difference between PP strapping and PET packaging?

- The PET packing belt belongs to the environmental protection type packing belt, the green environment protection can recycle, is suitable for the sustainable development, but the PP packing belt does not belong to the environmental protection packing belt. The PET belt is safer than the belt

- Q: Identification of the quality of the packing belt

- Packaged with quality, to look at the package with high purity polypropylene, currently on the market a variety of packing belt: pure polypropylene, polypropylene and polypropylene masterbatch, and recycled material, polypropylene and recycled materials and masterbatch. Packaged with transparent state production of pure polypropylene, polypropylene and masterbatch production package for translucent, polypropylene and packaged with basically opaque recycled material production, packaged with fully opaque polypropylene and masterbatch and renewable materials production. There are a total of renewable materials and calcium carbonate powder sandwich material production packing belt, completely regenerated material packaged with soft sandwich material belt production, only the surface of raw materials, the rest is calcium carbonate (lime). The quality of the packing belt depends entirely on the purity of polypropylene. The higher the purity of polypropylene, the better the pulling force of the packing strap.

- Q: How do you split the straps?

- After dressed again will lead to wear into one small mouth, tighten the strap, complete.

- Q: Identification of PP packaging belt

- PP packaging machine with the general white (other colors should be bright), quality is better, because these are not easy to mix old material.

- Q: Is packing with a shelf life?

- Metal belt pack also called steel, steel is processed into a certain process, there is a common blue metal packing tape and galvanized iron straps, iron belt can guarantee period is about three months, the galvanized iron sheet packaged with storage time can be longer, usually about half a year.

- Q: How to use the tie case packing belt?

- When you take the lead out, turn to the back of the suitcase and wrap it vertically around the trunk: (Note: the winding process should tighten the collar button)

- Q: What adhesive tape do you use?

- Common polyethylene, polypropylene resin as the main raw material, but also to nylon and polyester, polyester and the tensile strength of nylon strap, and polyethylene and polypropylene strapping polypropylene with low cost, good elasticity, can be selected according to different material strapping needs. ;

- Q: Baling machine; packing belt; tightness adjustment

- The automatic packer can not work automatically. First need to control system of packing tape to check whether the normal position, with a long adjustment is in the zero scale, and then check whether the wear process conforms to the standard, generally there are foreign bodies blocked, causing this kind of phenomenon.

Send your message to us

High strength straight disc painted packing tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 2500 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches