Geocells Ofisis Nomeri High Strength Polyester Geogrid with PVC Coated

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Polyester Geogrid:

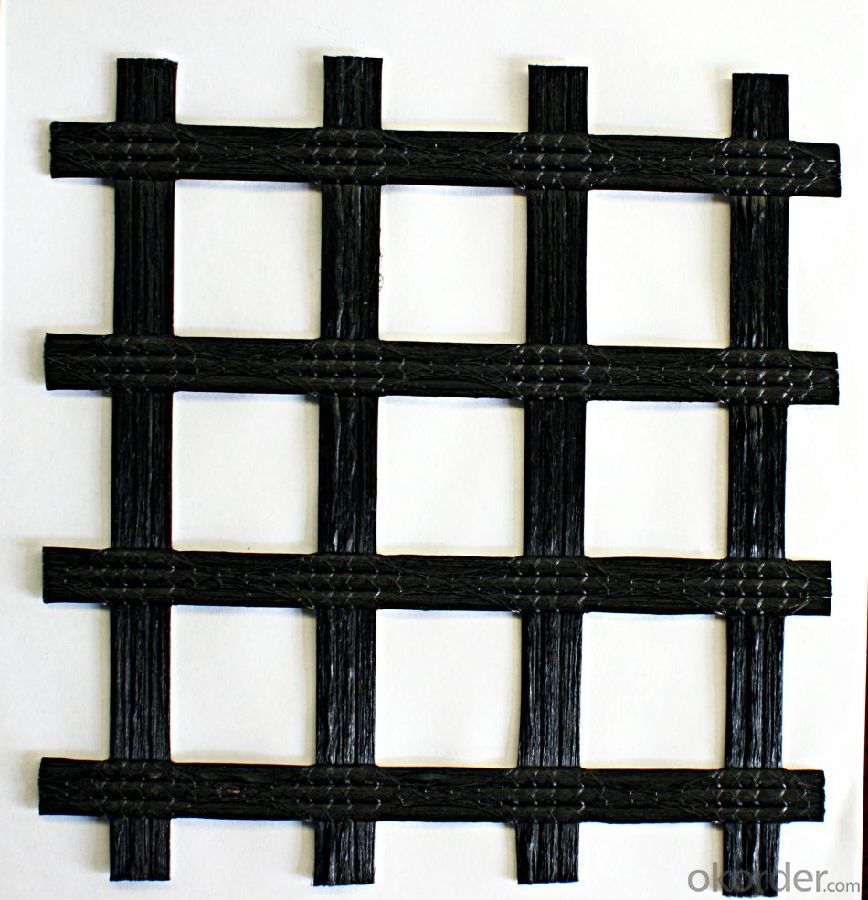

Polyester geogrid is a new kind of favorable earthwork base material to strength the road surface and roadbed, which composed of high strength polyester yarns coated with an inorganic sizing agent.

Polyester Geogrid known as PET Grid is woven by high strength polymer yarns as per desired mesh sizes and strength from 20kN/m to 800kN/m(Biaxial type), 40-25kN/m to 600-400kN/m(Uniaxial type). Woven PET Grid is created through interlacing, usually at right angles, two or more yarns or filaments. Exterior of PET Grid is coated with polymer or nontoxic substance material for UV, acid and alkali resistance and prevents the bio-decomposition.

PET Grid is widely introduced to the various fields of civil engineering, transportation engineering, and environment issues. The reinforced steep slopes, reinforced retaining earth walls, reinforced embankments, reinforced abutments and piers are typical applications where geogrids are used. The resulting grid structure possesses large openings that enhance interaction with filling material.

Features of Polyester Geogrid:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Application of Polyester Geogrid:

It mainly applied in strengthening soft ground of rail and road.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: How do geogrids improve the performance of geocell-reinforced slopes?

- Geogrids improve the performance of geocell-reinforced slopes by providing additional tensile strength and stability to the structure. They help distribute the load more evenly, reducing stress on the geocells and preventing soil erosion. Geogrids also enhance the overall durability and longevity of the geocell-reinforced slopes, making them more resistant to deformation and settling.

- Q: The price of the type of geogrid manufacturers is the best phone

- Thermal stability - the melting temperature of the glass fiber is above 1000 DEG C, which ensures the stability of the fiberglass geogrid in the paving operation.

- Q: 300 grams of geotextiles a square meter

- Geotextile is a kind of new material geosynthetics, the product is cloth, the general width of 4-6 meters, the length of 50-100 M. Geotextiles are divided into nonwoven geotextiles and nonwoven geotextiles.Ordinary 2 or so

- Q: What is the effect of geogrid aperture size on performance?

- The effect of geogrid aperture size on performance is that it directly influences the soil's interlocking capability with the geogrid. Smaller aperture sizes enhance the interlocking mechanism, leading to improved load distribution and higher tensile strength. On the other hand, larger aperture sizes may reduce the interlocking efficiency, potentially compromising the geogrid's overall performance in terms of reinforcement and stabilization.

- Q: Can geogrids be used in agricultural applications?

- Yes, geogrids can be used in agricultural applications. They are commonly used for soil stabilization, erosion control, and reinforcement of slopes in agricultural fields. Geogrids help to improve soil structure, prevent erosion, and provide support for heavy machinery, making them beneficial for various agricultural activities.

- Q: What is the difference between Geogrid and geogrid

- The geotextile is used to prevent seepage and the geogrid is used to reinforceThe geotextile is mainly used for seepage control, isolation, geogrid are generally used in reinforcement reinforcement, the two are essentially different, in the use of the process is sometimes used in the same project, for example, high-speed railway project is made of polypropylene production grid and polyvinyl chloride polymer and thermoplastic or die of two-dimensional grid or a certain height of 3D grid screen,

- Q: Are geogrids resistant to biological fouling?

- Yes, geogrids are generally resistant to biological fouling. Geogrids are made from materials that are not easily degradable, such as high-density polyethylene (HDPE) or polypropylene (PP), which makes them less susceptible to colonization by organisms and reduces the likelihood of biological fouling. Additionally, geogrids often have a smooth surface that makes it difficult for biofilms or other organic matter to adhere to the grid. However, it is important to note that while geogrids are resistant to biological fouling, they are not completely immune, and regular inspection and maintenance may be required to prevent any potential buildup of organic matter.

- Q: Are geogrids suitable for use in mining applications?

- Yes, geogrids are suitable for use in mining applications. They are commonly used in mining to reinforce soil and stabilize slopes. Geogrids provide excellent tensile strength and can withstand heavy loads, making them ideal for reinforcing mining structures such as mine walls, tailings dams, and haul roads. Additionally, geogrids are resistant to chemical and environmental degradation, ensuring long-term stability and safety in mining operations.

- Q: Can geogrids be used in retaining wall construction?

- Yes, geogrids can be used in retaining wall construction. Geogrids are commonly used to reinforce soil and provide stability to retaining walls by distributing the forces exerted by the soil. They are effective in preventing soil erosion, increasing the strength of the wall, and enhancing its overall durability.

- Q: What is the effect of installation damage on geogrid performance?

- Installation damage can significantly affect geogrid performance. Damage during installation, such as tears, punctures, or stretching, can compromise the integrity and functionality of the geogrid. These damages can reduce its load-bearing capacity, limit its ability to provide soil reinforcement, and decrease its overall effectiveness in stabilizing the soil. Therefore, proper installation techniques and careful handling are essential to maintain the geogrid's performance and ensure its long-term functionality.

Send your message to us

Geocells Ofisis Nomeri High Strength Polyester Geogrid with PVC Coated

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords