High Quality Aluminum Disc with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Disc Description:

Aluminum Disc is mainly used for general commercial and industrial uses, like the capacitor case, toothpaste case, medical tubes, kitchen ware, spray bottle, cosmetic case and glue tube case etc. With high quality casting and rolling coils or hot-rolled coils as raw materials ,it goes through different cold rolling deformation. slitting, annealing and finally stamping into an aluminum disc, then packaging for delivery

2.Main Features of the Aluminium Disc :

High quality & Competitive price

Fast heat transfer, evenly heated, save time and energy

High performance coating

Different thickness for your selection

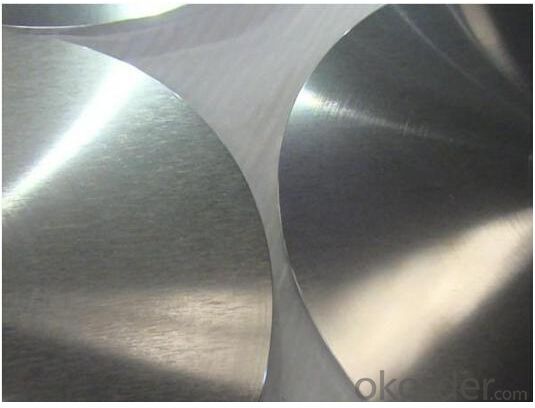

3. Aluminium Disc Images

4. Aluminium Disc Specification:

Product Type | Aluminium Circle / Aluminium Disc |

Product Martial | 1xxx series, 3xxx series, 5xxx series, |

Hardness state | H14, H16, H18, H24, H26, H22 and “O”. |

Product Size | Thickness: 0.3-6.0mm (+/-0.0.2mm), Diameter: 50-950mm |

Surface Treatment | mill finished, flat clean surface without scratches, wholes, oil dirty, oxidation, cutting edge no burrs. |

Processed | Deep drawings |

Min order quantity | 5 tons |

Short lead time | 20 days |

Application | Road sign, cookware, pot, pan, decoratating and so on |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

We are a professional factory with competitive price .

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③how about the sample?

Sample approval

- Q: This question asks about the impact of aluminum on human health.

- <p>Aluminum is a naturally occurring element that can be found in small amounts in various foods, water, and air. While it's not considered an essential nutrient, it's also not inherently harmful in small quantities. However, excessive exposure to aluminum has been linked to potential health concerns. Some studies suggest that high levels of aluminum might contribute to neurological disorders, particularly Alzheimer's disease, although the evidence is not conclusive. Aluminum can also cause digestive issues and bone disorders if ingested in large amounts. It's important to note that the human body does not absorb aluminum efficiently, and most ingested aluminum is excreted without issue. However, it's always advisable to minimize exposure to high levels of aluminum, especially for vulnerable populations such as infants and those with kidney issues.</p>

- Q: Explain the relationship between aluminum and iron in terms of their properties and uses.

- <p>Aluminum and iron are both metals with distinct properties that determine their various applications. Aluminum is lighter, more resistant to corrosion, and has good thermal conductivity, making it suitable for applications such as beverage cans, aircraft construction, and electrical wiring. Iron, on the other hand, is heavier, stronger, and more magnetic, which makes it ideal for construction materials, steelmaking, and electromagnets. They can be combined to form alloys, such as steel, which is an iron alloy with carbon and sometimes other elements, enhancing its strength and durability.</p>

- Q: This question asks about the impact of adding magnesium to aluminum alloys and how it changes their characteristics.

- <p>The addition of magnesium to aluminum alloys significantly improves their mechanical properties, particularly strength and rigidity. Magnesium enhances the alloy's resistance to corrosion and increases its formability. It also contributes to better weldability and reduces the likelihood of hot cracking during the welding process. However, the addition of magnesium can also lead to a decrease in electrical conductivity and may increase the alloy's susceptibility to stress corrosion cracking. The overall effect of magnesium on aluminum alloys is to create a material that is lighter, stronger, and more resistant to environmental degradation, making it suitable for various applications in the aerospace, automotive, and construction industries.</p>

- Q: Explain the interaction between aluminum and oxygen.

- <p>Aluminum and oxygen have a reactive relationship. When aluminum is exposed to oxygen, it forms a thin, protective layer of aluminum oxide on its surface. This oxide layer prevents further oxidation of the aluminum beneath it, making aluminum a corrosion-resistant metal. The reaction is exothermic and can be represented by the chemical equation: 4Al + 3O2 鈫?2Al2O3. This aluminum oxide layer is hard and stable, which is why aluminum is widely used in various applications where resistance to corrosion is important.</p>

- Q: This question seeks to understand the impact of aluminum exposure on human health, including potential risks and consequences.

- <p>Aluminum is a common element found in the environment, and while it is generally considered safe, there are concerns about its health effects on humans. High levels of aluminum exposure have been linked to neurological disorders, particularly Alzheimer's disease, although the relationship is not definitively proven. Aluminum can also cause bone diseases and anemia, as it can interfere with the absorption of calcium and iron. Long-term exposure to high levels of aluminum may lead to cognitive dysfunction and memory loss. However, the everyday exposure to aluminum from food, water, and medications is considered safe by health authorities, and there is no need for alarm in normal circumstances.</p>

- Q: This question asks if there are differences in how long different types of aluminum cookware can last.

- <p>Yes, there are differences in the durability of different types of aluminum cookware. Anodized aluminum cookware is more durable and resistant to scratches and corrosion compared to non-anodized aluminum. Cast aluminum cookware is heavier and more durable than aluminum clad cookware, which is a layer of aluminum bonded to a stainless steel core. The thickness of the aluminum also affects durability, with thicker aluminum being more resistant to warping and lasting longer. Proper care and maintenance also play a significant role in the longevity of aluminum cookware.</p>

- Q: What measures should be taken to ensure safety while working with aluminum?

- <p>When working with aluminum, it's important to follow safety precautions. Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a dust mask to prevent inhalation of aluminum dust. Ensure good ventilation to avoid the buildup of fumes. Use proper tools and equipment to handle aluminum, as it can become sharp and cause cuts. Be cautious of the heat generated during cutting or welding, as aluminum conducts heat quickly and can cause burns. Store aluminum in a dry place to prevent it from reacting with moisture, which can cause it to corrode. Lastly, be aware of the fire hazard associated with aluminum dust and take necessary fire prevention measures.</p>

- Q: Does aluminum have the ability to corrode or deteriorate over time?

- <p>Yes, aluminum can corrode, but it typically forms a protective oxide layer on its surface when exposed to air, which prevents further corrosion. This layer of aluminum oxide is very thin but strong and stable, making aluminum highly resistant to corrosion. However, under certain conditions such as exposure to certain chemicals or in the absence of oxygen, aluminum can still corrode. Corrosion can also occur if the protective layer is damaged or compromised.</p>

- Q: What are the typical applications for aluminum sheet metal?

- <p>Aluminum sheets are versatile and have numerous applications due to their lightweight, corrosion resistance, and strength. Some common uses include construction for roofing and siding, automotive parts such as body panels and heat sinks, packaging for food and beverages, aerospace for aircraft components, and in the manufacturing of electronic devices due to its good thermal conductivity. They are also used in signage, furniture, and various decorative applications.</p>

- Q: What are the effects of aluminum on water quality, and how does it impact aquatic ecosystems?

- <p>Aluminum can significantly affect water quality, particularly in acidic conditions. It becomes more soluble and bioavailable in water with low pH, which can occur due to acid rain or natural soil acidity. High levels of aluminum can be toxic to aquatic life, causing physiological stress and even death in fish and other organisms. It can damage gill tissues, impairing respiration, and affect reproduction and growth. Aluminum can also bind to organic matter in the water, affecting nutrient cycling and potentially leading to eutrophication. In addition, aluminum can leach into water from various sources such as antiperspirants, which can contribute to its presence in aquatic environments.</p>

Send your message to us

High Quality Aluminum Disc with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches