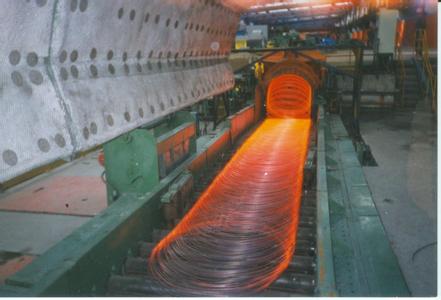

High grade hot-finished rod

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wire is 5-22 mm diameter hot rolled round steel, or rather the cross section of special-shaped steel. Due to the delivery of the goods in the form of wire rod, so it is also known as wire rod.

Wire cross-section circumference is small, common specifications for 5-13 mm diameter. According to the different can be divided into the high speed wire rod mill (line) and ordinary wire line (at) two kinds.

Generally made from ordinary carbon steel and high quality carbon steel wire rod. According to the directory and USES different steel distribution, mild steel wire including ordinary hot rolled plate, the high quality carbon steel wire rod, carbon electrode wire rod, conditioning threaded rod, wire rope with wire rod, piano wire with wire rod and stainless steel wire rod, etc.

1. Ordinary low carbon steel hot rolled plate (GB701-65), normal low carbon steel hot rolled plate by low carbon ordinary carbon structural steel or the carbon structural steel rolling of low yield point, is dosage the biggest, the most widely used in varieties of wire rod, also known as the cord.

Main use: general line is mainly used in construction of reinforced concrete structure for reinforcement, can also be made steel wire, cold drawn to pull for strapping, etc.

2. Ordinary no twist accused of cold, hot rolled low carbon steel wire rod (ZBH4403-88), no twist accused of cold, hot-rolled wire rod by no twist to control cooling after rolling in high speed wire-rod mill, material is the same as the general line, but no twist accused of cold, hot-rolled wire rod with high dimensional accuracy, good surface quality and higher mechanical properties, etc.

Main application: no twist accuracy of cold, hot-rolled wire rod size control points A, B, C level 3. A, B, C level precision is applicable to drawing, construction, packaging and electrode and other purposes, B, C level accuracy is suitable for processing into bolts, screws and nuts, etc.

3. Quality carbon steel wire rod (GB4354-84), high quality carbon steel wire rod is made of high quality carbon structural steel rolling. Is one dosage larger varieties of wire rod variety.

Main application: high quality carbon steel wire rod is mainly used for processing and manufacturing carbon spring steel wire, oil quenching tempering carbon spring steel wire, prestressed steel wire, high strength and high quality carbon structural steel wire, galvanized steel wire, galvanized wire rope, etc.

4. Quality carbon steel no twist accused of cold, hot-rolled wire rod (ZBH44002-88), no twist accused of cold, hot-rolled wire rod quality carbon steel by the high-speed wire mill rolling with no twist, disposed of by controlled cooling after rolling. Compared with the high quality carbon steel wire rod, high dimensional accuracy, good surface quality, have higher mechanical properties.

Main USES: the main purpose is the same as the high quality carbon steel wire rod. Often used in the manufacture of carbon spring steel wire, oil quenching tempering carbon spring steel wire, prestressed steel wire, high quality carbon structural steel wire, galvanized steel wire, etc.

5. Wire rope with wire rod (YB349-64), wire rope with wire rod is one of the high quality carbon structural steel hot rolled plate.

Main application: wire rope with wire rod available 35 and 40, 45, 55, 60, 65, 70, 75, 80 and 85 steel grade high quality carbon structural steel manufacture. Chemical composition meet GB699 (high quality carbon structural steel technical conditions).

6. Wire rope with no twist accused of cold, hot-rolled wire rod (ZBH44004-88), wire rope with no twist charged with hot and cold rolled plate and with high quality carbon structural steel, in the absence of torsion wire mill rolling, controlled cooling after rolling. This rolling of wire rod, high dimensional accuracy, good surface quality, superior mechanical properties.

Main application: mainly used for drawing steel and steel strand steel wire rope.

7. Carbon electrode steel wire rod (GB3429-82), carbon electrode made by high quality carbon structural steel hot rolled low carbon steel rod.

Main application: mainly used in the manufacture of manual arc welding welding core.

8. No twist accused of cold, hot rolled carbon electrode steel wire rod (ZBH44005-88), no twist accused of cold, hot rolled carbon electrode steel wire rod is rolling on blockade twist wire mill, and made controlled cooling after rolling. Its high dimensional accuracy, good surface quality, superior performance, is a kind of high quality welding rod steel wire rod.

Main application: mainly used in the manufacture of a coated electrode steel reinforced carbon steel hot rolled plate.

9. Alloy structural steel hot-rolled wire rod (GB3077-82), alloy structural steel hot-rolled wire rod by alloy structural steel rolling material. Alloy structural steel with a total of 26 steel group, the 78 steel grades. Each manufacturer according to buyer's requirements and different USES to choose brand for production.

Main use: alloy hot rolled wire rod structure is mainly used for drawing wire, metal products and components.

10. Carbon tool steel hot-rolled wire rod (GB1298-86), carbon tool steel by high quality or high quality high carbon steel rolling. Processing performance and wear-resisting performance is good, the price is cheap.

Main USES: mainly used in drawn steel ratio and making tools, etc.

11. Alloy tool steel hot-rolled wire rod (GB1299-77)

Alloy tool steels is in chrome is joined on the matrix carbon tool steel, tungsten, molybdenum, vanadium, silicon, manganese, nickel and cobalt alloy elements and tempered steel. Compared with the carbon tool steel. It has good hardenability, small heat cracking tendency, the characteristics of high wear resistance and heat resistance. Alloy tool steel hot-rolled wire rod by 33 five steel group steel grade of alloy tool steel material and rolled. Respectively by the dalian steel, benxi steel mills and steel mills and other unit production in shaanxi province.

Main use: is suitable for measuring tool, cutting tool and cold and hot die, shock resistant, etc.

12. Spring steel hot-rolled wire rod (GB1222-84)

Spring steel is used in the manufacture of springs or other steel grade of elastic element. Springs and elastic element mainly USES the elastic degeneration absorb and store energy, alleviate vibration, shock, or make parts to complete some action for the purpose. Since it is in shock, vibration or even under the working conditions of periodic alternating stress for a long time, so the spring steel with high yield strength, especially must have higher showed (the ratio of yield strength to tensile strength) and fatigue strength of high elastic, high resistance to high temperature and corrosion resistant performance. The surface of spring steel shall also have the good quality.

Spring steel with carbon spring steel and alloy spring steel, a total of 17 brands.

Main use: spring steel hot-rolled wire rod is mainly used in the production of various USES of helical spring.

13. Ball bearing steel hot-rolled wire rod (YB9-68), referred to as "bearing steel, ball bearing steel is used in the manufacture of various types of rolling bearing ring (sleeve) and steel rolling body (the ball). Due to the particularity of its USES for bearing steel has high and even hardness and wear resistance, high elasticity and fatigue strength. Enough toughness and hardenability, at the same time in the atmospheric environment or lubricant has certain corrosion resistant ability. Some special use of the rolling bearing also require high temperature resistance, corrosion resistance, nonmagnetic, ultra-low temperature, high precision, long life and other performance. So the choice of bearing steel and steel than ordinary steel strict quality.

Bearing steel is usually refers to the high carbon chromium steel, there are also carburizing bearing steel, high carbon chromium stainless bearing steel. Commonly used in rolling bearing steel hot-rolled wire rod steel grade five.

Main use: ball bearing steel hot-rolled wire rod is mainly used in the manufacture of bearing steel ball (ball), etc.

14. Stainless steel wire rod (GB4356-84), stainless steel wire rod was organized by a variety of brand different size of stainless steel hot rolling.

Main use: stainless steel wire rod is mainly used in the manufacture of stainless steel wire, stainless spring steel wire, stainless wire upsetting and stainless steel wire. According to the main industrial USES for to distinguish, stainless steel wire rod are stainless steel and stainless acid-resistant steel wire rod.

15. Welding of stainless steel wire rod (GB4241-84), welding of stainless steel wire rod and stainless steel wire rod is different in chemical composition. In order to guarantee its excellent welding performance, improve the quality of weld, welding of stainless steel wire rod in composition marked characteristics are low carbon, phosphorus, sulfur, less toxic impurities, such as nickel, chromium content is higher.

Main application: mainly used in the manufacture of welding electrode wire and steel core.

- Q: How is steel wire rod used in the production of wire mesh reinforcement?

- Steel wire rod is an essential component in the production of wire mesh reinforcement. It serves as the main raw material for manufacturing wire mesh, which is widely used in construction and other industries for reinforcing concrete structures. To produce wire mesh reinforcement, steel wire rod is first processed through a series of manufacturing steps. The rod is typically drawn through a series of dies to reduce its diameter and increase its length. This process, known as wire drawing, results in a thinner and longer wire with improved mechanical properties. The drawn wire is then fed into a specialized machine called a wire mesh welding machine. This machine uses electric resistance welding to join the wires together, forming a grid-like pattern. The welding process ensures that the wires are securely bonded at their intersections, creating a sturdy and durable wire mesh. The wire mesh reinforcement is used in various construction applications, such as in the construction of concrete slabs, walls, and columns. It is embedded in concrete structures to provide additional strength, prevent cracking, and increase the overall load-bearing capacity. The wire mesh acts as a reinforcement, distributing the forces and stresses evenly across the concrete, thereby enhancing its structural integrity. Furthermore, wire mesh reinforcement is also utilized in other industries, including agriculture, mining, and manufacturing. In agriculture, it is commonly used as fencing to secure livestock and crops. In mining, wire mesh is employed for safety purposes, such as preventing rockfalls and supporting tunnel walls. In manufacturing, wire mesh is utilized for filtration, separation, and containment purposes, among others. In summary, steel wire rod plays a crucial role in the production of wire mesh reinforcement. Its transformation through wire drawing and subsequent welding forms the basis for creating durable and versatile wire mesh. This reinforcement is widely used in construction and other industries to enhance the strength and integrity of various structures.

- Q: What are the different corrosion resistance properties of steel wire rod?

- The corrosion resistance properties of steel wire rod can vary depending on factors such as the composition of the steel, the presence of protective coatings or finishes, and environmental conditions. Some types of steel wire rod, such as stainless steel, exhibit excellent corrosion resistance due to high levels of chromium and other alloying elements. These types of steel are particularly resistant to rust and corrosion caused by moisture or exposure to corrosive substances. On the other hand, carbon steel wire rod may have lower corrosion resistance and may require additional protective measures, such as galvanization or coating, to prevent corrosion. Overall, the corrosion resistance properties of steel wire rod can range from high to low depending on the specific type of steel and the conditions it is exposed to.

- Q: What are the dimensions and sizes available for steel wire rod?

- The dimensions and sizes available for steel wire rod vary depending on the specific needs and requirements of different industries. Generally, steel wire rod is produced in diameters ranging from 5.5 mm to 22 mm. However, larger or smaller sizes can be customized based on the customer's request. Additionally, the length of steel wire rod typically ranges from 2,000 to 2,500 meters.

- Q: What are the weight requirements for steel wire rod coils?

- The weight requirements for steel wire rod coils can vary depending on the specific application and industry standards. However, in general, the weight of steel wire rod coils typically ranges from a few hundred kilograms to several metric tons. The specific weight requirements are determined by factors such as the intended use of the wire rod, the type and grade of steel being used, and the transportation and handling capabilities of the facilities involved. It is important to consult the appropriate industry standards and specifications to ensure compliance with weight requirements for steel wire rod coils in a particular application.

- Q: How does the thermal conductivity of steel wire rod vary with different grades?

- The thermal conductivity of steel wire rod typically varies with different grades. Higher-grade steel wire rod tends to have a higher thermal conductivity compared to lower-grade steel wire rod. This is because higher-grade steel wire rod is usually made with superior quality materials and has a more refined structure, allowing for better heat transfer. However, it is important to note that the exact variation in thermal conductivity can depend on various factors such as alloy composition, heat treatment, and processing techniques used during the manufacturing process.

- Q: How is the steel wire rod market affected by political and economic instability?

- The steel wire rod market is significantly impacted by political and economic instability. These uncertainties create fluctuations in demand and supply, which in turn affect the prices of steel wire rod. Political instability, such as changes in government policies or trade disputes, can disrupt international trade and lead to market volatility. Economic instability, such as recessions or inflation, can reduce consumer spending and construction activity, directly impacting the demand for steel wire rod. Overall, political and economic instability introduce uncertainty and risk into the market, making it challenging for businesses to plan and make informed decisions.

- Q: How are steel wire rods used in the manufacturing of piano strings for musical instruments?

- Steel wire rods are used in the manufacturing of piano strings for musical instruments by being drawn through a series of dies to achieve the desired thickness and strength. These wire rods are then wound tightly around a core wire to create the piano string. The high tensile strength of steel wire makes it ideal for withstanding the tension required to produce the desired pitch and resonance in a piano.

- Q: How is steel wire rod used in the production of nails and fasteners?

- Steel wire rod is a crucial component in the production of nails and fasteners. It serves as the primary raw material, providing the strength and durability required for these products. To manufacture nails and fasteners, steel wire rod goes through a series of processes. First, it is heated and rolled into a coil shape to increase its ductility and reduce its thickness. This process is known as hot rolling and gives the wire rod the necessary properties for further manipulation. Following hot rolling, the wire rod undergoes cold drawing, where it is pulled through a series of dies to reduce its diameter further. This process enhances the wire's surface finish and mechanical properties, such as tensile strength and hardness. The drawn wire is then cut into specific lengths, depending on the desired nail or fastener size. These lengths are then fed into a nail making machine or a fastener production line. In the case of nails, the wire is fed into a cutter that forms the nail heads and points. For fasteners, the wire is shaped and formed into the desired product, such as screws, bolts, or rivets. The quality of the steel wire rod used in the production of nails and fasteners is crucial for the end products' performance. It must have excellent tensile strength, as nails and fasteners are subjected to significant stresses when used. The wire rod also needs to be corrosion resistant to ensure that the nails and fasteners can withstand exposure to moisture and other environmental conditions without deterioration. Overall, steel wire rod plays a vital role in the production of nails and fasteners, providing the necessary strength, durability, and corrosion resistance required for these essential products.

- Q: What is the manufacturing process of steel wire rod?

- The manufacturing process of steel wire rod involves several steps. It begins with the melting of iron ore and other materials in a blast furnace. The molten iron is then refined and converted into steel through various processes such as oxygen blowing, electric arc furnaces, or basic oxygen furnaces. Once the steel is produced, it is cast into billets or blooms, which are then hot rolled into wire rod form. The hot rolling process involves passing the billets or blooms through a series of rollers to reduce their thickness and shape them into long, continuous wire rods. After hot rolling, the wire rods are cooled, straightened, and cut into desired lengths. They may undergo additional treatments like surface finishing, heat treatment, or galvanization depending on their intended use. Finally, the wire rods are coiled and packaged for shipment to various industries where they are further processed or used directly in applications such as construction, automotive, or manufacturing.

- Q: How is steel wire rod used in the production of wire for mattress springs?

- Steel wire rod is an essential element when producing wire for mattress springs. It acts as the primary raw material used to manufacture the robust and long-lasting wire required for mattress springs. To initiate the manufacturing process, careful selection of steel wire rod is crucial, considering its desired characteristics such as tensile strength, flexibility, and corrosion resistance. Subsequently, the rod undergoes a series of procedures to convert it into wire suitable for mattress springs. The initial step involves heating the steel wire rod and passing it through a sequence of dies that gradually reduce its diameter. This process, known as wire drawing, refines the mechanical properties of the wire and ensures uniformity in thickness. Once the wire has been drawn to the desired diameter, it undergoes further treatment to enhance its strength and resilience. This may involve heat treatment procedures like annealing or quenching, which improve the wire's flexibility and resistance to fatigue. Following the treatment, the wire is coiled onto spools or reels, ready for use in the manufacturing of mattress springs. The wire is then fed into specialized spring-making machinery, where it is shaped into the required size and shape. These machines utilize a combination of bending, coiling, and twisting movements to create the intricate spring designs commonly found in mattresses. The utilization of high-quality steel wire rod in the production of wire for mattress springs ensures that the springs are strong, durable, and capable of withstanding the constant pressure and weight placed upon them. Consequently, mattresses made with these springs provide excellent support and comfort to sleepers. In conclusion, steel wire rod plays a vital role in the production of wire for mattress springs. It undergoes various processes to refine its properties and is then shaped into the necessary form to create robust and resilient springs. This guarantees that mattresses manufactured with these springs offer superior support and durability to users.

Send your message to us

High grade hot-finished rod

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords